The design scheme of ventilation is its axonometric scheme. The ventilation system is a branch system. Each branch starts from the grille and ends at the mouth of the mine. Thus, the branches have different lengths, the greatest - for the branches starting on the first floor, and the smallest - on the last. The air in the system moves under the action of natural pressure resulting from the difference in density between the cold outside and the warm inside air. The natural disposable pressure for each calculated branch Drе , Pa, is determined by the formula

Drе = hg ( rн - rвн) , (4.3)

where h is the difference between the elevations of the mouth of the mine and the louvered grille, m; rн and rвн are the densities of external and internal air, respectively, kg / m3.

The densities rn and rвн are taken according to the design temperatures of the outside tn and internal air tвн and can be determined from reference tables or formulas (1.5) and (1.6). The calculated outdoor temperature tn in accordance with the standards [2] is assumed to be +5 ° C, regardless of the area of construction . At a lower temperature, the natural available pressure in the ventilation increases, and the system provides air exchange more than the calculated one, and at a higher temperature, the air exchange in the rooms can be enhanced by opening the vents and windows. From formula (4.3) it is obvious that in ensuring air exchange, the upper floors are in less favorable conditions, since the available pressure here is less.

In the design scheme, all sections of the calculated branches are numbered; the boundaries of the sections are the nodes for changing the air flow rate or changing the duct section. For each section on the diagram indicate its length, air flow and in the future - the dimensions of the channel section.

The task of aerodynamic calculation is the selection of such sections of ducts in which the total pressure loss in the design branch å (Rl b + Z) will be equal to or less than the current pressure

S (R l b + Z) £ Drе, (4.4)

where R is the specific pressure loss due to friction in metal ducts, Pa / m; l is the length of the duct, m; b - coefficient taking into account the roughness of the channel walls; Z - pressure loss in local resistances.

A pressure margin of 10–15% is recommended.

Aerodynamic calculations are performed on the tables or nomograms compiled for round steel ducts (Appendix 12). All the parameters of the aerodynamic calculation are interrelated in them: air consumption L, m3 / h; duct diameter d, mm; speed V, m / s; specific pressure loss on friction R, Pa / m; dynamic pressure Pv = pV 2/2.

All tables and nomograms for aerodynamic calculations are made for circular ducts, therefore, when calculating rectangular ducts, their dimensions must be reduced to the equivalent diameter of a circular duct

Deq = 2a in / (a + b) , (4.5)

where a and b are the dimensions of the channel section, mm.

Increased compared with steel channel roughness is taken into account by roughness coefficients b, given in Table. 4.1.

Table 4.1

The values of roughness coefficients b

Speed movements air m / s | Duct material | |||

slag gypsum | shlakobeton | brick | gridded plaster | |

0.4 | 1.08 | 1.11 | 1.25 | 1.48 |

0.8 | 1.13 | 1.19 | 1.4 | 1.69 |

1.2 | 1.18 | 1.25 | 1.5 | 1.84 |

1.6 | 1.22 | 1.31 | 1.58 | 1.95 |

The calculation of each section of the branch is performed in the following order.

1. Determine the required channel area Fтр , m2

Ftr = L / (3600 Vrec), (4.6)

where L is the calculated air flow rate, m3 / h; Vrek is the recommended speed, assumed to be 0.5–1.0 m / s for vertical and horizontal channels and 1–1.5 m / s for the mine.

2. A standard channel section is selected with a close value of area F.

3. According to the formula (4.5) is the equivalent diameter deq of the duct.

4. Using tables or nomograms (Appendix 12) for air consumption L and equivalent diameter de equate the specific pressure loss to friction R, speed V and dynamic pressure Pv.

5. Determined by the pressure loss on friction R l b , Pa, and local pressure loss Z , Pa

Z = S x Pv, (4.7)

where x - coefficients of local resistance in the area, taken on adj. eleven.

6. Calculate the pressure loss in the areas (R l b + Z), PA.

After that, the total pressure loss in the branch S (R l b + Z), Pa is found, and the condition is checked by formula (4.4). If, on the first attempt, the inequality is not satisfied, the duct section should be changed. Similar calculations are made for other branches. All calculations are performed in tabular form according to examples 7, 8. In the course project, for branches of one ventilation unit, all branches of one ventilation unit should be calculated, for attic buildings - branches from the first and last floors.

Example 7. Design and calculation of the ventilation system of a bescherdny building.

Baseline: a three-story residential building with the characteristics of examples 1-4. A ventilation system should be developed for three-room apartments located one above the other, with toilets, bathrooms, kitchens with electric stoves and living rooms with a total area of 60 m2.

Decision. Standards for residential buildings are recommended duct exhaust ventilation system with a natural impulse. Exhaust grates are installed in areas of intense air pollution: in kitchens and bathrooms 0.2 m below the ceiling, vertical channels are installed in brick walls, canal mouths are raised above the roof 1.0 m. From each apartment air is drawn through two channels - from the kitchen and from the toilet, the bathroom is ventilated through the toilet, for which a vent is provided in the partition between these rooms.

Due to the fact that the building is non-sluggish, each ventilation duct has its own release into the atmosphere. The canals are grouped into two blocks - 3 channels from three toilets and one bathroom located above each other, and 3 channels from kitchens.

Each channel block is closed from precipitation by an umbrella.

Normalized air exhaust: from the kitchen with electric stove - 60 m3 / h; from the toilet and bathroom - 25 m3 / h; from the living room - 3 m3 / h per 1 m2 of floor space, i.e. 180 m3 / h.

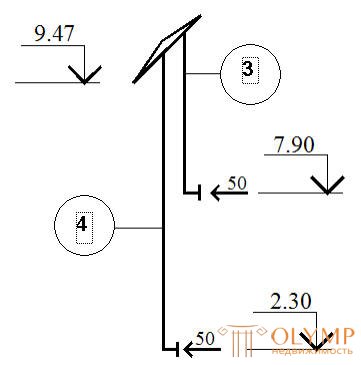

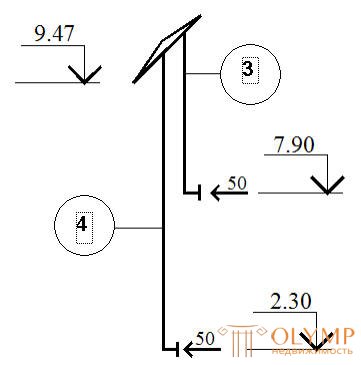

Fig. 4.4. The design scheme of the channels of the ventilation system of the confusionless building

The condition (4.2) is not fulfilled: 60 + 25 + 25 <180. As a result, the calculated air exchange of the kitchen is increased to 130 m3 / h.

The calculated outdoor air temperature for the ventilation system is tн = 5 ° С, this temperature corresponds to the air density rн = 1.27 kg / m3. For the kitchen at

tвн = 15 ° С, rвн = 1.22 kg / m3, for the air removed from the toilet and the bathroom, the temperature is taken to correspond to the arithmetic average temperature of these rooms (25 + 16) / 2 = 20.5 ° С and r20, 5 = 1.20 kg / m3.

Channels from toilets on the 1st and 3rd floors are calculated (Fig. 4.4). The height of the channels is determined by the difference in elevations of the mouth of the ventilation shaft and louvered grilles. H1 = 7.17 m, h3 = 1.57 m.

The natural pressure for each channel is determined by the formula (4.3)

Dr1 = 7.17 ∙ 9.81 (1.27 - 1.20) = 4.92 Pa;

Dr3 = 1.57 ∙ 9.81 (1.27 - 1.20) = 1.08 Pa.

Local resistances in all channels are similar: an entrance with a turn through a louvered grille x = 2; exhaust shaft with umbrella x = 1.3. The sum of the local resistance coefficients is Sx = 3.3.

The value of the roughness coefficient b of brick channels is taken from Table. 4.1 (b = 1.45).

All calculations for the ventilation system B-1 of the sanitary facilities are summarized in Table. 4.2. The effective pressures in some branches considerably exceed the pressure losses, therefore, the regulation of air exchange by a louvered grille is required.

Example 8 Design and calculation of the attic building ventilation system.

Baseline : a three-story residential building with dimensions similar to those specified for examples 1–5 with an attic floor.

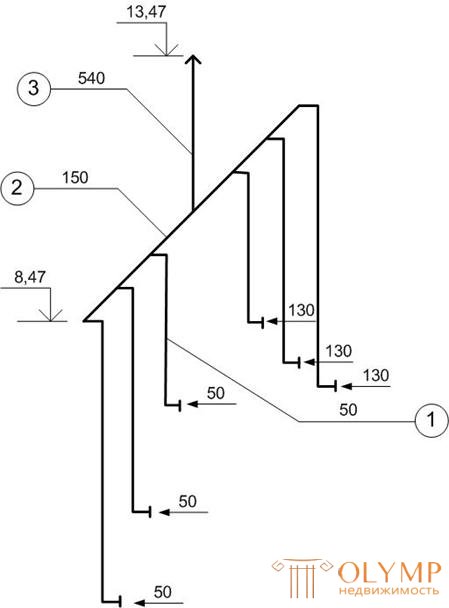

Decision. The layout of the ventilation system channels in the apartments is the same as in the previous example, that is, in the B-1 ventilation unit 3 channels are provided from the kitchens and 3 from the corresponding sanitary facilities. In the attic, these 6 vertical channels are united by a horizontal slag-gypsum channel, in the center of which a metal shaft with a height of 5 m is equipped. Channels from the upper floors are located unfavorable closer to the exhaust shaft. Axonometric system diagram is shown in Fig. 4.5. Aerodynamic calculation branches are presented in Table. 4.3.

In the example, only one of the most unfavorable branches is calculated - from the toilet (including the bathroom) of the 3rd floor (sections 1–2–3 in the diagram in Fig. 4.5). Natural pressure in this branch is determined by the formula (4.3)

Drе = 5.57 ∙ 9.8 (1.27 - 1.20) = 3.82 Pa.

Local resistances in the branches: entrance with turning through louvre x = 2; 2 tees with rotation x = 0.3 each; exhaust shaft with umbrella x = 1.3. The sum of the local resistance coefficients is Sx = 3.9. The roughness coefficient for a vertical channel in a brick wall is 1.43. For horizontal slag gypsum canal and mine b = 1.18.

Table 4.2

Table of aerodynamic calculation of air ducts of the system

natural exhaust ventilation of a non-residential building (for example 7)

room plot | Air consumption L , m3 / h | Section length l , m | Channel size a ´ in , mm | Equiv. diameter d eq , mm | Area F , m2 | Speed V , m / s | R , Pa / m | R l b, Pa | Pv = Pa | Sx | Z, Pa | (R l b + + Z) , Pa |

one | 50 | 7.17 | 140´140 | 140 | 0,0196 | 1.0 | 0.12 | 1.23 | 0.6 | 3.3 | 1.98 | 3.21 |

Dre = 4.92 Pa. Pressure margin 34% | ||||||||||||

3 | 50 | 1.57 | 140´270 | 184 | 0.0378 | 0.52 | 0.036 | 0.08 | 0.15 | 3.3 | 0.49 | 0.57 |

Dre = 1.08 Pa. Pressure margin 47% | ||||||||||||

Table 4.3

Table of the aerodynamic calculation of the natural system

exhaust ventilation attic building (for example 8)

room plot | Air consumption L , m3 / h | Section length l , m | Channel size a ´ in , mm | Equiv. diameter d eq , mm | Area F , m2 | Speed V , m / s | R , Pa / m | R l b, Pa | Pv = Pa | Sx | Z, Pa | (R l b + + Z) , Pa |

one | 50 | 0.57 | 140 × 270 | 184 | 0.0378 | 0.52 | 0.036 | 0.03 | 0.15 | 2.3 | 0.35 | 0.38 |

2 | 150 | 0.4 | 200 × 200 | 200 | 0.04 | 1.1 | 0.1 | 0.05 | 0.6 | 0.3 | 0.18 | 0.23 |

3 | 540 | 5.0 | 300 × 300 | 300 | 0.09 | 1.7 | 0.12 | 0.71 | 1.7 | 1,3 | 2.21 | 2.92 |

S (R l b + Z) = 3.53 Pa | ||||||||||||

Dre = 3.82 Pa . Pressure margin of 8%. | ||||||||||||

Fig. 4.5. The design scheme of the channels of the attic building ventilation system

The calculation showed that the pressure loss in the calculated branch is 3.53 Pa, less than the natural disposable pressure of 3.82 Pa, i.e. the projected ventilation system is operational.

Similarly, in the course project should be calculated and other branches of the system.

TEST QUESTIONS

1. What forces move the air in the ventilation system?

2. Show the calculated branches and areas in the system developed in the course project.

3. What is the purpose of aerodynamic calculation of the ventilation system?

4. How are the pressure losses in the ducts determined?

5. From which rooms is air removal recommended at the ventilation device?

6. What materials are used for ventilation ducts?

7. Why is the radius of the ventilation system limited?

8. How is air exchange in the premises of buildings determined?

9. How is the ventilation of living rooms?

10. On which floors do the ventilation systems work in the most favorable conditions and why?

11. What is the design of ventilation systems in high-rise buildings?

12. What is harmful, and why is their concentration in indoor air normalized?

13. How is the inflow of external air in the ventilated residential premises?

14. What hazards are usually characteristic for residential premises, for industrial premises?

15. How can a tenant regulate air exchange in a residential area?

Что бы оставить комментарий войдите

Комментарии (0)