In decorative solutions that are treated with acid, do not introduce dry building paints (pigments). The color of the plaster is determined by the color of natural aggregates, for example, stone, marble and granite crumbs of different colors, crumb bricks, anthracite.

When applying such plasters between the grips, no joints in the form of dark stripes are formed. With this surface treatment method there is no loss of solution. Etching with acid is more productive than chiseling, forging with bushings or skarpels. However, textures treated with acid can only be of the same relief, since the aggregates use medium-sized ones.

When working with acids, you must observe the following rules. Acid transferred only together and stored in the appropriate place. When preparing the solution, the acid should be poured into the water in small portions and mix everything up; it is necessary to work in rubber gloves and respirators.

Consider some types of decorative plasters treated with acid.

Plaster "under granite" is durable and for decades retains its decorative properties. A different crumb is used for the decorative solution: white crumb is mixed with brick crumb, anthracite crumb is added.

The preparatory layer is made of cement-lime mortar. For coating, solutions of the following composition are used: 1 part of Portland cement 400-500, 5 parts of a crumb of one or several colors with grains of 1 to 4 mm and 0.1 parts of mica. First, a dry mixture is prepared, from which a semi-dry mass is then obtained in a mortar mixer or manually, slightly wetting the mixture with water. When using white chips, white cement is used.

Preparatory and skid solutions are applied as follows. Surfaces are hung, marks and lighthouses are arranged, and a preparatory layer is applied from the spray and the soil in a mechanized way or manually. The applied and leveled soil is scratched with grooves to create roughness and left to dry. After drying put overcoat. Before applying the coating

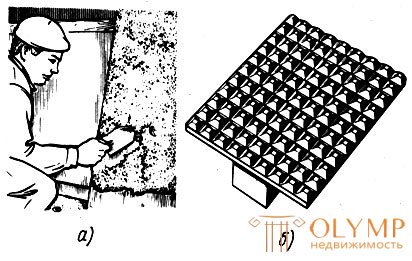

The soil is 1-2 m2 in size, moistened with water with a brush and smear a layer of cement paste with a creamy consistency 1-2 mm thick. A plaster spatula or trowel (Fig. 117, a) is immediately smeared with a dry covering on this layer. Coat should be flat and dense, layer thickness up to 4 mm.

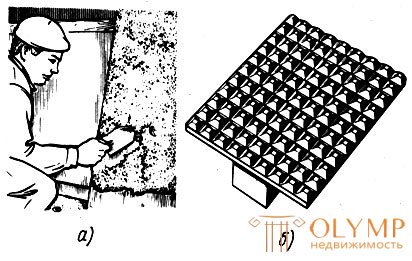

After completing the coating with an area of 1-2 m2, wash it with water from the spray gun so as to wash off the excess cement from the front surface of the coating. After that, the surface is punched with a float size of 15 x 15 cm (Fig. 117, b) with a bronze plate and pyramidal teeth to level the surface, smooth out the marks of the scapula or trowel and give relief to the cover.

Fig. 117. Application of the solution with a trowel (a) and grater-stamping (b) for surface treatment

Dry the sheet for 3-4 days and start treatment with acid.

For etching prepare a 10% hydrochloric acid solution. Acid is applied to the surface with a brush or spray and give the acid some time to destroy the remains of cement, dust and other contaminants on the surface of the aggregate. The end of the etching is determined by the fact that the acid solution stops boiling.

After that, wash the acid-treated surface with water to stop the acid from acting on the cement and prevent the formation of yellowness.

Consider a possible way of organizing labor when finishing the facade of a large building with plaster "under the granite".

A brigade of 32 people to perform work is divided into three links. To perform the work, the brigade was assigned a mortar pump with a capacity of 6 m3 / h, two mortar mixers, 100 m of hoses, 15 inventory mortar boxes, plastering blades, trowels with even edges, semi-graters, rules, 10 graters-forgings, 5 hand sprayers and 10 foot spray guns .

The duties between the links are distributed as follows.

The second link consists of eleven plasterers: two of the 2nd category, five of the 3rd category and four of the 4th category. This link applies a preparatory layer in a mechanized way, i.e. splashing and priming. Plasterer-driver of the 4th category with an assistant plasterer of the 2nd category take the imported solution, bring it to the working consistency using a mortar mixer and serve it with a mortar pump to the workplace.

The third link consists of nineteen people: a team leader-plasterer of the 6th category, one plasterer of the 4th category and seventeen plasterers of the 5th category.

Work among members of the link is distributed as follows. The plasterer of the 4th category prepares a semi-dry mortar mix in a mortar mixer. Seventeen plasterers of the 5th category are engaged in applying the facial overcoat. They moisten the surface with water with grips of no more than 2 m2, they cover it with a layer of 1-2 mm of pure cement paste and with a trowel they smear the prepared covering solution for gluing, that is, from the blade a layer 4-5 mm thick. The solution is smeared without gaps and possibly smoother. After spreading to clean the crumb and mica from the cement paste stuck to them, the plastered surface is washed with water using a hand sprayer. Then, in order to eliminate traces from the scapula or trowel on the covering layer and to create relief, the surface is treated with float-stamping and rusts are cut, dividing the surface, if necessary, into separate parts (hooks, stones).

After three or four days, i.e., after setting the solution, the applied plaster is finally cleaned of cement and dust, washing with 10% hydrochloric acid solution. The acid is applied with a spray and, as it is cleaned from the cement tracer, it is washed with water using a spray.

Plaster with quartz sand perform so. The preparation layer, i.e. spray and primer applied over the beacons of cement-lime mortar. Then level it and scratch it. After that, a covering face layer is prepared, which consists of 7 parts of quartz sand, 3 parts of lime paste, 1 parts of white cement mark 200 and 0.1 parts of mica. Water taken on demand.

The prepared solution is applied to the surface with a layer of 2-3 mm, leveled and rubbed. After drying, etch the surface with a 5% hydrochloric acid solution, followed by washing with clean water.

Что бы оставить комментарий войдите

Комментарии (0)