The main task of a conventional drill is to drill holes in various materials with low and medium hardness. This tool is not suitable for working with hard materials, as it is necessary to drill them with a bang. Even a hammer drill cannot effectively hammer brick or concrete. However, this does not mean that the scope of use of electric drills is limited. The universality of this tool can be envied if you know how to use it correctly. About what you can do with a drill - read below.

The easiest way is to use a drill instead of a polisher. It can be used to polish surfaces made of wood, metal and other materials, clean iron products from rust, remove old paint, scrape away dried dirt and perform other tasks. All that is required for this is a special nozzle umbrella.

There are special wire brushes-brushes with a shank chambered for optimum removal of rust, dirt and old paint. There are also special nozzles with a flat surface on which sandpaper circles or a mesh are attached. They are used for cleaning and roughing or finishing sanding.

Another type of fixture is a drill bit for polishing, designed for finishing. It is a disc covered with “zero” sandpaper, or a hard fibrous material (felt, felt). The task of such nozzles on the drill is to polish surfaces, up to achieve their mirror shine.

When carrying out repairs in an apartment or house, attracting a concrete mixer is not always possible and justified. Cooking a few buckets of cement mortar or plaster using a large concrete mixer — the idea is like going for bread on a heavy truck. Therefore, the question of whether it is possible to use the drill as a mixer, is quite natural and explainable. After all, manually making the batch is not very convenient, and the power tool greatly simplifies the task.

It is quite possible to use a drill for mixing the solution, such an application does not harm the tool and does not pose any increased danger to people, since the tool motor works in the normal mode, and sharp moving nozzles are not used. In order to use the drill as a mixer, you need a special nozzle for it. It costs almost a penny (10-100 hryvnia), and will last for a long time. There are nozzles mixers of various shapes, lengths, different material.

To quickly and accurately knead the solution with a drill, you need not to look for the cheapest nozzle. This is especially important if the composition of the solution contains solid and coarse-grained fractions (sand, gravel, fine crushed stone). Poor quality metal (without alloying additives that increase strength) is quickly erased and deformed. Also, when choosing a nozzle for mixing the solution with a drill, you must consider the type and thickness of the shank. It is important that it is compatible with the drill chuck. Usually these have a round or multifaceted shank, up to 1 cm thick. Nozzles for perforators can be equipped with a shaped SDS shank.

Also, in order to use the drill as a mixer, it is desirable to have a second handle. Without it, you will have to hold the tool by the body in the area of the ventilation slots, and this will lead to overheating of the motor. If there is no side handle with the drill, you can buy it, the issue price is up to 50 UAH.

Construction screwdriver is a miniature drill, so many are wondering whether you can use a drill as a screwdriver. However, another node has been added to the design of the latter. This is a force adjustment mechanism that prevents excessive tightening of the screw, stalling of the head or slot, as well as licking the bits. When the screw is screwed in - the tool stops rotating the cartridge. At the drill, such a function is simply absent, which, however, does not prevent using it instead of a screwdriver.

Screwdriver: a ring with numbers adjusts the force of the screw screw

Sometimes a drill instead of a screwdriver becomes indispensable, especially if you need to screw long screws into hard wood. Battery models have a low-power motor that does not always cope. But the drill for 400-600 W easily twists the screws of almost any length.

Before you tighten the screws with a drill, you need to take into account several features of this mode of operation of the tool and follow the recommendations mentioned below.

Subject to the advice of the process of tightening screws will be without complications. Having become accustomed, it is possible to twist the screws with a drill faster than with a specially designed tool. But the answer to the question of whether it is possible to use a hammer drill as a screwdriver is somewhat more complicated. The fact is that hammer drills are larger and heavier than usual. When you turn off the shock mode - you can safely use the tool instead of a screwdriver, but fatigue will come much faster.

Deciding whether to use a drill as a grinder is somewhat more difficult. The obstacle becomes safety regulations when working with sawing disc power tools. Firstly, such a tool must have a casing above the disk on the employee’s side. Secondly - in the process of work it is forbidden to be in the plane of its rotation. If there is no problem with the second moment (the disk will rotate in a plane parallel to the worker), then with the case it is more difficult. Therefore, use a drill instead of the grinder "can, if carefully."

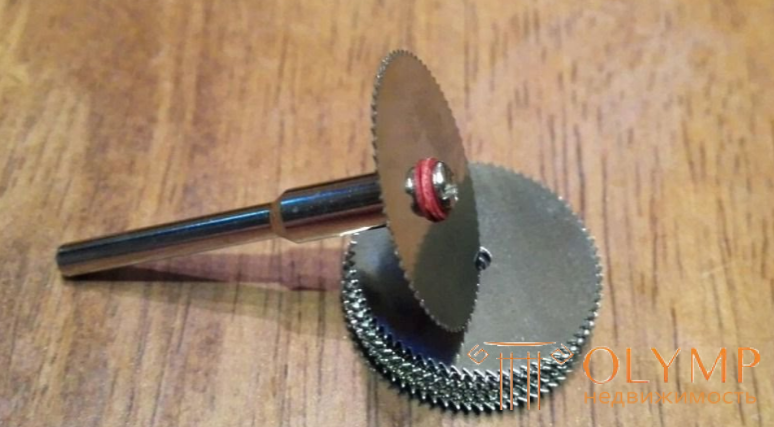

To use the drill as a grinder, you need a special device to install the disk. The adapter from the drill to the grinder is a rod that has a thread on one side and a slot for a cartridge on the other. In the middle of the rod there are two washers between which the cutting disc is clamped. After installing the adapter, the disk is perpendicular to the drill body and therefore does not pose a danger to the worker. However, there are some limitations of this application of the drill.

Use the drill as a grinder can be used with small parts and blanks, with a small amount of work. She can cut thin plastic pipes (water and gas), corners and channels, fittings. You can also use a drill instead of the grinder when working with boards, slats, bars of small thickness. The optimum disc diameter is 10-15 cm. But for making long longitudinal cuts (when cutting sheet metal, wide boards, sheets of facing and finishing materials) a drill with a nozzle for a grinder is not enough. It is very difficult to get a long and even line with it.

Drill with an adapter on the grinder is not suitable for cutting sheet metal and other thin but wide materials (why - see above). However, it is quite possible to use a drill for cutting metal. Moreover, the above method is completely safe and much more convenient than cutting with disc tools. All that is needed for this method is a nozzle on a drill for cutting metal, popularly called "cricket".

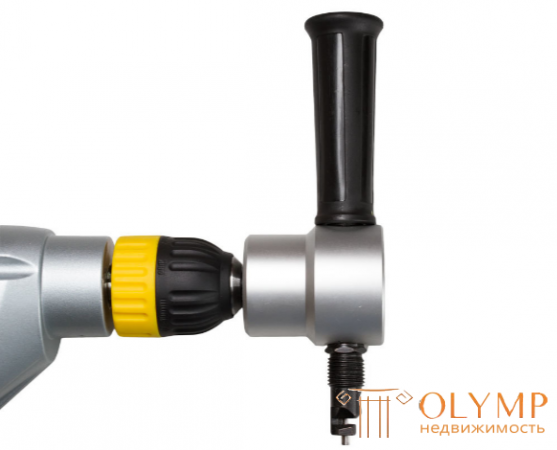

Vysechnye scissors or "cricket" is a special corner adapter designed for figure cutting of sheet metal and other thin materials. It converts the rotational movements of the cartridge into the reciprocating stroke of a special toothed knife, which cuts the sheet.

In addition to convenience and safety, the advantage of punching shears for a drill is the ability to cut metal and corrugated flooring. The fact is that disc tools are not recommended for cutting them, and manual metal shears lead to profile deformation. The only drawback of the adapter to the drill for cutting metal is the price. Vysechnye scissors can have a cost comparable to the price of a cheap drill. However, even at such a cost, cutting metal with a drill is cheaper, since professional cutting scissors are quite expensive and redundant for household needs.

To use the drill for cutting metal - you need to install a "cricket", mark the cutting line (you can use a marker) and begin to advance by adjusting the position of the scissors with the help of their handle. The adapter allows you to cut with a drill not only flat and even sheets of metal, but also blanks of any other shape.

Что бы оставить комментарий войдите

Комментарии (0)