The basis of drywall constructions are plates consisting of a gypsum core pasted over from both sides with a special cardboard.

Gypsum panels do not contain toxic components, odorless, electrically neutral, they also have the ability to absorb excess moisture and release it into the surrounding air when it is deficient. Gypsum panels are also moisture resistant (for rooms with high humidity, such as bathrooms, kitchens); fire resistant (for rooms with increased fire hazard - sheathing attic rooms, gas pipelines), as well as special applications (reinforced, bulletproof).

Due to their relatively small mass, plasterboard constructions are indispensable in buildings where the load on the floor should be limited (old reconstructed buildings), as well as where it is impossible to use traditional finishes (houses with wooden partitions, floors, “shingles” plaster).

Under wall cladding, heating devices, pipes, electrical and telephone cabling can be hidden. Wall cladding structures are suitable for finishing mixed masonry, uneven surfaces, for quick and easy repairs. They include the supporting frame, embedded insulation, covered with gypsum panels.

Fig. 15.1.– Color range of panels

The sphere of business related to the production and sale of drywall systems is a rather tasty morsel of a large “building pie”. The pace of development of this market segment is so impressive (35-40% per year) that any other industry can envy them. So far the best has been done by the German company KNAUF, which, as a domestic producer, controls about 70% of the drywall market.

Gypsum plasterboards (slabs) are far from a new type of product on the domestic market of building materials. Dry gypsum plaster (as they used to call gypsum plasterboard) began to be produced from the beginning of the 1950s. However, this product did not receive proper distribution on the market - outdated technologies for the production of drywall did not contribute to its introduction into construction practice. Only in recent years, as the technology of "dry construction" advanced, did the real possibilities and advantages of drywall get a proper assessment. Began an active development of the business associated with the import, and then with the production of drywall systems.

The benefits of "dry" technology. Plasterboard constructions are used today for the decoration of walls, ceilings and installation of partitions in rooms, although there may be other options. The most popular are conventional gypsum boards with a thickness of 12.5 mm (it is estimated that up to 60% of sales accounted for them). About 20% of sales are moisture-resistant plates with a thickness of 12.5 mm and about 10% - ordinary plates with a thickness of 9.5 mm.

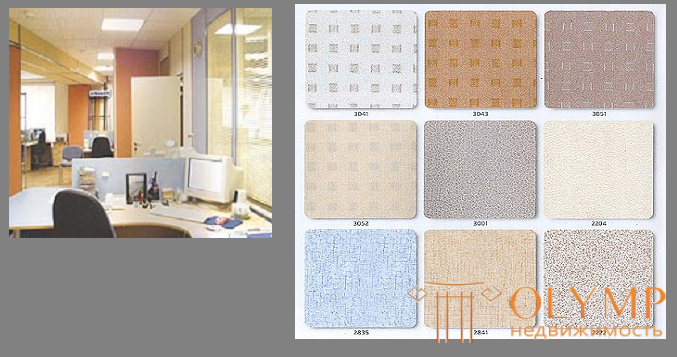

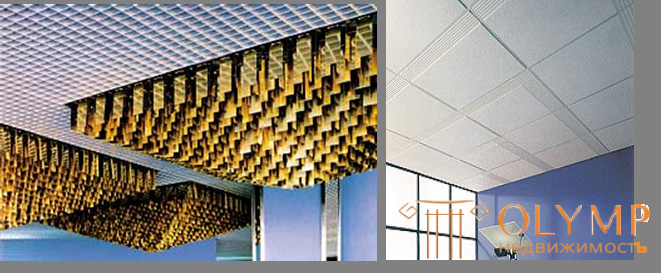

Fig. 15.2. - Plasterboard constructions

Five or six years ago, only imported goods prevailed on the Ukrainian drywall market (although its sales could hardly be called impressive). It was represented by such well-known manufacturers as KNAUF, LAFARGE, RIGIPS, who imported products from their factories in Austria, Germany, Poland, Russia, France and other countries. However, today the situation has radically changed: firstly, the capacity of the market itself has significantly increased (from 3 million square meters in 1998 to 20 million square meters in 2002), and secondly, the flow of imported gypsum board is noticeably dried up - its market share decreased from 100% to 30%.

Changes in the assortment can affect the increase in the supply of so-called "special products" (special acoustic, hygienic, refractory plates, "dry" gypsum floors, etc.).

Wall and ceiling decoration with drywall. Everyone knows that before you begin to finish the walls, you need to put them in order and, first of all, plaster and clean the cracks and level the surface. Much more profitable and spectacular wall and ceiling plasterboard. This fashionable material today - well forgotten old - is simply dry plaster. And in the decoration it is simpler than the traditional wet. So, drywall - gypsum sheets, covered with a thin, but durable cardboard. Their length is 2.5-3.5 m., Width 1.2-1.3 m. And a thickness of 8-10 mm. To cover the concrete walls with drywall, you must first nail the frame of wooden boards or battens to the wall with concrete nails (dowels).

Before starting work, it is necessary to accurately calculate the dimensions of the frame: it is important that, at the joints of sheets of dry plaster, the width of the frame rails should be at least 7.5 cm. Vertical boards or laths are nailed to the wall with a length of at least 7-10 cm. it is necessary to drill holes and insert stoppers, and already in them to drive in nails at a distance of no more than 50 cm from each other. Sheets of drywall are nailed to the prepared framework so that between them there is a space of 4-5 mm for the subsequent finishing of seams.

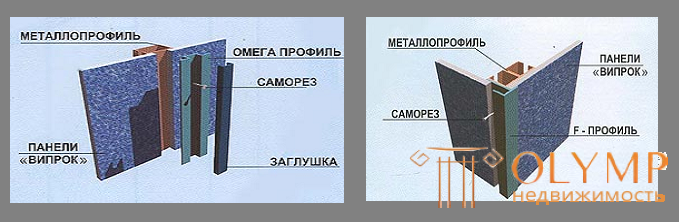

Fig. 15.3. - Profile for drywall

Between the plasterboard and the wall, in turn, there also remains an empty space of about 20-25 mm, which creates additional thermal insulation. But dry plaster does not necessarily nail to the wooden frame, thereby taking away such precious centimeters from their living space. You can simply glue the sheets to the wall with the help of the so-called gypsum paste mastic consisting of gypsum and 2% aqueous solution of bone glue (glue is necessary so that the gypsum does not harden at the same minute). Having prepared the mastic, throw it on the wall with tubercles using a spatula within the limits of the size of the gypsum plasterboard at a distance of 35-40 cm from each other. Along the edges of the sheet mastic arrange not tubercles, and a solid bed. Throwing mastic tubercles, immediately press the drywall to the wall and tap on it, leveling the surface. Veneer the corners of the room without leaving seams. If you have to finish any protrusion, be sure to glue the joints of the external seams with gauze strips and carefully putty. You can also cover the outer corners with wooden or plastic corners. Fill the seams between the sheets with gypsum dough and fill. Drywall is the best foundation for wallpaper. They can be glued without any pretreatment, the only thing that needs to be done is to cover nail heads with nitro enamel or alcohol varnish in order to avoid corrosion. And you can not glue the walls, but, for example, whitewash or paint with glue or oil paint, as usual plastered surfaces. It is not recommended only to use lime paints, as they do not adhere well to drywall.

Fig. 15.4 - Usage drywall for walls and ceilings

and devices of partitions in rooms

Dropped ceilings. More than half of the sales of suspended ceilings in the Russian market are accounted for by Armstrong.

The second half of our market was divided by several large and respected firms, also smaller ones. Armstrong, by popularity rating, is followed by another US company, Celotex. Further, the German firm “USS Donn”, often referred to in advertisements as “Donn”. Then the Swedish Ecophon (Ecophon) and the Finnish Akusto (Akusto) - both are part of the trans-national concern Saint-Gaben.

Tiled suspended ceilings of these companies mainly form the tastes of the Russian buyer today. All these are companies with experience and name, but their ceilings, of course, differ in quality, purpose and price. Each has its own characteristics. But you do not have to chase cheap and buy ceilings unknown and, therefore, unreliable company.

A suspended ceiling (frame) and plates made of solid or soft mineral fiber, usually 1.5 cm thick and measuring 60 x 60 cm or 61 x 61 cm, are included in the false ceiling. The difference of one centimeter is not accidental: the first size is designed for Europeans with their metric system of measures, and the second - on the Americans (61 cm - this is 2 feet). And in Europe, and we sell those and other plates.

Fig. 15.5. - Suspended ceiling design

A suspension system is a set of metal slats, having the shape of the letter “T” in cross-section and interconnected in a modular grid. The principle of hanging is simple. Holes are drilled in a conventional ceiling with a drill or a perforator. They are inserted dowels. Dowels are attached with special hooks, on which a modular grid is hung. Into the resulting metal frame insert the plate. They can also be removed if necessary. Along the perimeter of the room is finished with a ceiling plinth.

When buying a suspended ceiling, you need to pay close attention to the "unity" of the plates and the suspension system. Unscrupulous sellers sometimes strive to stick a "non-native" suspension system. That is, the plates - one manufacturer, and the suspension system - the other. Such a ceiling may not collapse, but can easily be deformed. Difficulties in repair and maintenance in this case are also guaranteed - different systems do not always interfere with each other.

Material. The Armstrong, Selotex, and USG Donn firms produce ceiling tiles made from solid mineral fiber with the addition of cellulose, which gives them greater strength. However, everything in this life has its downside: if you properly hit something heavy on this plate, then dents will appear on it. The products of the concern “Sen Gaben” are “soft”, in fact it is compressed glass wool. To the touch "soft" plate, as the name implies, softer. When struck, they are less prone to deformation than solid. Another advantage of "soft ceilings" is that it is convenient to transport them, they will not break.

Colour. Most often, the ceilings of suspended ceilings are monotonously white, the classic texture is smooth, but can also be with a rough surface, “worms”, dots, notches, with embossed geometric patterns, etc.

If desired, the plates can be painted with water-based or latex paints. For example, Armstrong manufactures Dune ceilings, originally painted in soft pastel colors (light green, sky blue, pale pink, and peach). According to statistics, almost 99% of buyers in our country are ordered exclusively white plates.

Fig. 15.6. - Texture and color of panels

Groups The ceilings of different companies are completely similar in appearance, but quite different from each other, both in quality and purpose. Large companies even have their own classification of ceilings in appearance and quality. Tile suspended ceilings "Armstrong", for example, are divided into 4 groups, each, in turn, several types of completely different (smooth, rough, etc.). Armstrong ceilings are divided into four groups:

1. Basis

2. Prima

3. Functional

4. Designer (exclusive)

"Basis" - the most simple. They can not be hung in basements, in bathrooms and in general in rooms with high humidity. These plates are “not friendly” with water, they can leak, sag, and absolutely exactly deform - something like blisters will appear on them.

The slabs of the “Basis” group, as a rule, are white, with “worms” or dots. But such ceilings are the cheapest and, as a result, are best sold. Buying "Basis" together with a suspension system, you pay from 4 to 5.5 $ / sq. In this group there are four types of ceilings, including "Baikal", "Cortega" and "Tatra". They differ from each other only in the different direction of the “worms” and the relief of the plate. The ceilings of a similar class from Donn and Selotex are a bit more expensive.

"Prima" - plates adapted to the "life" in the climate of Central and Eastern Europe. And that means in the Russian too. They feel great even at 95% humidity, unlike the Basis ceilings, designed for humidity up to 70%. Ceilings "Prima" will not sag because of the accumulated moisture and will not bubble. But still it is better not to mount them in the bathrooms and in other "wet" rooms.

The warranty on this type of tiled ceilings (subject to installation on the Armstrong suspension system) is 10 years. Prima costs a little more than the ceilings of the Basis group: an average of 15%.

Functional ceilings are several types of ceiling tiles. Each of them has certain specific properties.

Acoustic ceilings perfectly absorb sound indoors and provide sound insulation outside. The plates of soft fiberglass are loose in their structure (apparently, the sound “gets stuck” in them). This is the first way. The second: many tiny holes are made in the plates, this method is called microperforation.

“Soft” fiberglass ceilings produced by Ekofon and Akusto are often called acoustic suspended ceilings. These firms specialize in the production of precisely “soft” and precisely acoustic ceilings. The plates perfectly absorb the sound inside the room, so they will not hear you in the next rooms. But the conversations of neighbors, you can successfully overhear. Not the ceiling, but just a godsend for a spy. Minus these ceilings - the monotony of design. In addition, "soft" plates, like a cigarette filter, absorb all the nastiness from the air. Therefore, after a while such a ceiling turns yellow and even blackens. But acoustic ceilings perfectly resist moisture.

Hygienic ceilings are ideal for medical and childcare facilities: if they get dirty, they can be washed. These plates are covered with vinyl film, so they are easily washed with a high pressure jet. Moreover, the bacteria on this film die, and you can optionally cover the plates with a special antimicrobial film.

Moisture-resistant ceilings are great for rooms with 100 percent humidity (for example, in the bathroom or pool). The secret is simple - silicon containing admixture is mixed into these plates, and moisture-resistant plates are also very dense. This is noticeable even in weight: if an ordinary plate weighs 3.5-4.5 kg / sq. M, then it is moisture resistant - 7 kg / sq. M. When leakage, it so strongly absorbs moisture that it can withstand up to 17 kg. And when the stove dries, it acquires the same weight, volume, shape, and color (except for those “unfortunate” cases when neighbors from above have rusted water down on your ceiling).

Designer (or exclusive) ceilings amaze imagination with a variety of textures, reliefs and colors. Designer ceilings perfectly fit into almost any interior. You can disguise the suspension system, choosing it to match the color of the plates, - the “square” frame will be almost invisible. You can make designs of the suspension system in the tone of baseboards, doors, vases and even office folders.

As for the plates themselves, in the family of designer ceilings there are more than 15 varieties. There are slabs on which the squares are pressed out, "slats", scars and other geometric patterns. There are plates and with more interesting reliefs. At the request of the customer they are combined in such a way that very intricate patterns are obtained on the ceiling.

Another interesting nuance. If desired, if a flat surface tires the eye, you can make a chocolate bar out of any suspended ceilings. It is done this way: the suspension system is sunk into the interior, and the plates turn out to be convex, like squares in a chocolate bar, and each ceiling plate is finished with a edging. Such a plate edge (step) is called a “microlook” or “tegular”.

At least ten fixtures can be installed in the suspended ceiling. And instead of several plates, you can insert lamps of the same size as the plates themselves (the so-called “trough” lamps with fluorescent lamps). Or in each plate to make a hole and put a spotlight. As a rule, serious firms selling suspended ceilings offer their clients all the necessary lighting equipment.

Repair and removal of the suspended ceiling is extremely simple. Wanted: ladder, spare plate and three minutes of time. The damaged plate is removed, the new one is inserted. Everything. If you did not take care of the tile "nest egg" when you bought the ceiling set, do not worry. Just purchase another box (usually there are 14 or 16 tiles in it; if these are tiles of exclusive models, then 8 pieces each). The only problem is finding the exact same ones.

Fig. 15.7. - Variants of interior design using suspended ceilings

Also we advise when buying, be sure to ask what category of combustibility your chosen ceiling belongs to. Of course, all foreign manufacturers of tiled ceilings have a European certificate. But this does not exempt them from receiving Russian: according to our laws, all construction products must be certified for compliance with Russian fire safety standards. Sellers say that tiled suspended ceilings of all firms represented in our market fall under the most “combustible” category G1. This means that it is difficult to set fire to the ceiling plates even with a blowtorch, and they will not notice a short circuit at all. In addition, the plates practically do not smoke. Therefore, it turns out that suspended ceiling ceilings can be considered as an additional element of protection of a conventional ceiling from fire.

Все-таки подвесные плиточные потолки были придуманы специально для служебных помещений. Во-первых, официальный, во-вторых, подвесной потолок съедает до 10 см высоты – согласитесь, для типовых квартир это просто недопустимое расточительство. Из всех названных выше фирм-производителей подвесных плиточных потолков о жилых помещениях позаботился только «Aрмстронг». Фирма выпускает потолочные панели из твердого волокна специально для дома, которые так и называются – «Дома» («Doma»). Крепятся безо всякого каркаса: они приклеиваются прямо на обычный потолок, забирая всего 1,3 см высоты или «пришиваются» строительным степлером к деревянной обрешетке (в этом случае вы потеряете максимум 5 см высоты). Подвесные потолки для дома действительно выглядят изысканно и по-домашнему. Но истинно подвесными потолками их, пожалуй, назвать нельзя.

Fig. 15.8 - Solid Fiber Ceiling Panels

Suspended ceilings made of plasterboard can adjust the ceiling height, hide communications, frame elements (beams, beams), as well as give the ceiling various forms (arched, vaulted, slanted). Raster and halogen lamps can be built into the ceiling. In combination with heat and sound insulating materials optimal thermal performance and sound insulation characteristics are achieved.

Что бы оставить комментарий войдите

Комментарии (0)