The organization of the workplace of the weaver, equipping it with appropriate tools, accessories, and comfortable furniture is one of the most important conditions. When weaving, the workplace includes a table (workbench) up to 65 cm high, 75 cm long and 55 cm wide, with a drawer for storing tools and a chair.

The main tools for the manufacture of various woven products are as follows: beater (iser), zhamka, awl, knife set, shears, hammer, pliers, pliers and needle nose pliers, trough, set of patterns, wedges, etc.

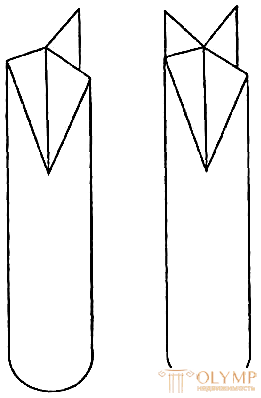

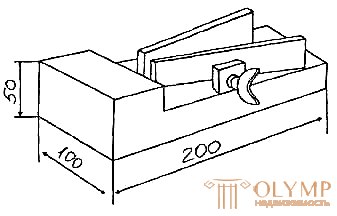

Bilo, or Isera (Fig. 1), serves to enable the weaver to compact the weaving, and if necessary, if it is too tight to the previous row, to straighten it. Beats come in different sizes, the use of one or another depends on the size of the product. In large cases, the upper end ends with a crochet hook, which serves to bend thick rods in the corners when weaving large objects.

|

Fig. 1. Beat (gauge), dimensions in millimeters |

Characteristics of isers in mm | ||||

| Length, L | Diameter, d | Width h | Thickness S | Cut for crease, alpha |

| 380 | 40 | thirty | 18 | 30 x 30 |

| 280 | thirty | 25 | 13 | 25 x 25 |

| 250 | 25 | 15 | ten | 20 x 20 |

Zhamka (Fig. 2) serves to straighten and bend the sticks. At one end there is a round hole for leveling and bending the sticks, on the other - a quadrilateral cut-out for their wringing. Zhamki come in different sizes: their length varies from 250 to 380 mm, the diameter of the hole from 25 to 40 and the width of the notch from 20 to 30 mm.

|  |

Fig. 2. Zhamka (dimensions in millimeters) |

Production of plates, tires and tapes . The plate is produced by splitting into two halves, and the tire into three or four parts, the tape is made from the tire by planing it. Tape, planed on both sides, called chips, and with one -gloss. The gloss is used to cut the core and soft wood so as to produce a ribbon with an untouched outer side that retains its luster. When weaving ribbon tape is used for finishing and bonding connections.

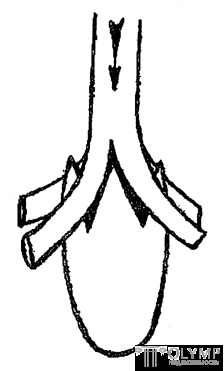

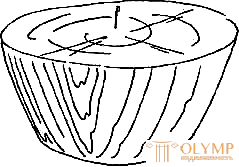

Before proceeding to splitting willow rods into plates and tires, they are soaked in several stages in water for 4-5 hours. To obtain plates, the rod is split with a knife into two parts. When splitting the rod into tires, the tip ends of the rods 10-25 mm long are cut, the cut is split with a knife into three or four parts and an appropriate drum is inserted (Fig. 3, a, b).

| Fig. 3. Cleaves for splitting the rod: a - into three parts; b - into four parts |

|  |

Cleaves are made of steel, horn, bone or hard wood; their length is 6-8 cm, diameter 3 cm. One end of the cleft is convex, and on the other there are 3-4 equal cut-out incisors.

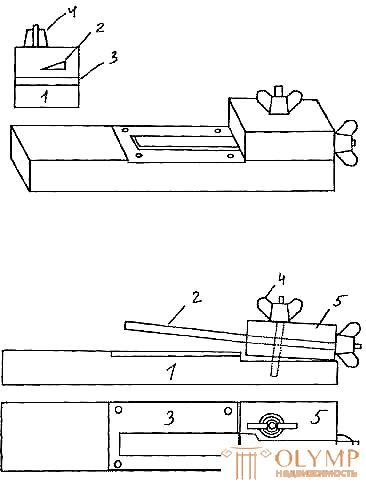

Tires planed with a special machine, and in his absence - manually. In the latter case, use a simple planing tool, called the chauffeur (Fig. 4).

|  |

| Fig. 4. Shaving tool shof: 1 - a knife; 2 - screw; 3 - plank; 4 - board (base); 5 - bar. | Fig. 5. Shmol |

The basis of the chauffeur is a piece of the board (4) to which a plate (3) is attached. In the last screw, the knife (1) is fixed with a one-sided facet. Between the plate (3) and the base (4) there is a spring on the screw 2 connecting them, which allows you to adjust the height of the knife. The wooden parts of the chauffeur can be replaced with metal. A chauff made entirely of metal is more portable, but less convenient to work with, especially if it has to be performed in a cold, unheated room.

For planing by the chauffeur the tires, previously soaked in water, are laid out on the left side with their apical ends, they take the tire by the left hand by the tip, they are inserted into the screen between the knife and the plank, they pull it with the right finger to the knife. By pulling the tire through the chrome several times, a gloss tape of the desired thickness is obtained - from 0.3 to 0.5 mm.

Mechanical planing machine for weaving tape

Schmol For the final trimming of planed tires they use another plow, the so-called shmol. Its purpose is to align the edges and get the tape of the same width throughout.

The basis of the shmola (Fig. 4) is a piece of board, to which are attached two knives with a one-sided facet. The distance between them, adjustable by screws, is set depending on the required width of the tape, which is pulled between the knives. Operations and the sequence of their execution on Shmola are identical to those when working on a chauffeur. Tapes are pre-moistened and laid out according to size. Having set the knives to the desired width, stretch the ribbon between them.

The awl is necessary for the weaver to strengthen the handle, seal the remaining ends of the rods when weaving bends, and also for sealing the weaving in the manufacture of small articles, especially from glossy tape. With a large awl, similar to a shoemaker, they attach the bottom of the basket to the pallet, on which weave the side walls connected to the bottom, this allows the weaver to rotate the basket when weaving around the axis of the awl. Sometimes, instead of sewed, they use a load that is put on the bottom of a basket weaving on the table. The weaver has a set of awls of different sizes, all of which must be sharp, well-honed, made of high-quality steel.

Knives - cutter and basket knife. The cutter (a wide, short knife with an obliquely sharpened tip) is used to carefully trim the ends of the rods during operation. It is made of high quality steel so that you can give it the sharpest edge needed for clean work. Basket knives are used for planing and cutting rods and sticks.

The sawing tools include hand saws for various purposes, sizes and shapes of blades, hacksaws, jigsaws, butt saws, and saws for cutting veneer. Bow saws are used to cut the material across, along, at an angle, zapilivaniya eyes, spikes; cutting ends on the "mustache"; for precise adjustment of the ends of the bars. The decoration is necessary for cutting in wood of non-through slots and grooves. Hacksaws with a wide blade serve for sawing the spikes of the lugs, for cutting across the fibers of wide boards and shields, and with a narrow blade for cutting curvilinear blanks. A hacksaw with a pick will be useful in the case of cutting the ends on the "mustache" during trimming, for cutting small parts. Jigsaws are used when it is necessary to cut a hole or a complex contour in subtle details, in artificial plates imitating natural materials, for example, bone.

It should be noted that the thicker the saw, the more intense the divorce. For thin saws, the divorce should be 2 times the thickness of the saw. It should also be remembered that when sawing soft wood, the divorce should be more, and hard - less.

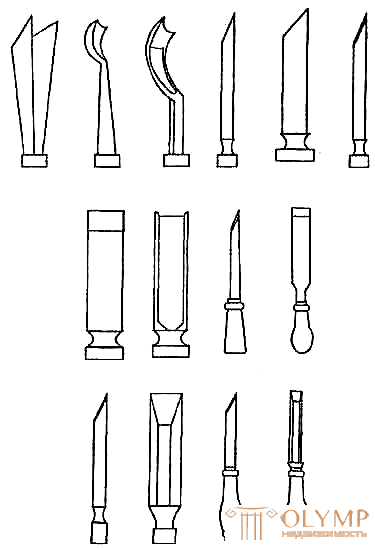

Joiner's chisels, cranberries and chisels (Fig. 6). The bits have different cutting widths (from 3 to 16 mm) and different grinding angles (from 25 to 35 °). It serves as a chisel for sampling lugs, sockets, grooves, cutting of through and blind holes, cleaning the surface. Chisels clean up the holes, bringing them to the desired size, and on minor works on cutting holes using only this tool. Chisels are flat and semicircular. For contour and triangular-grooved, relief and sculptural threads, etc., use chisels of the corresponding profile.

Only with the help of a planing tool can you get products with exact dimensions, a wide variety of profiles and shapes, with the necessary surface roughness. All these tools have almost the same device: a wooden or metal base, a knife and a wedge (screw) for fastening the knife in the body to a certain height from the tool's sole. All the difference of these tools in the device knife, its width and profile.

For a better material inlet, a Sherbel's knife is made semicircular, and its departure from the sole is 1-3 mm. The grooves line the plane with a straight cutting edge. For cleaning surfaces using files with coarse and fine notching and grinding skins.

|  |

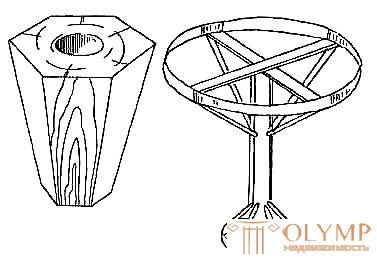

| Fig. 6. Joiner's chisel and chisel chisels | Fig. 7. Bugeli |

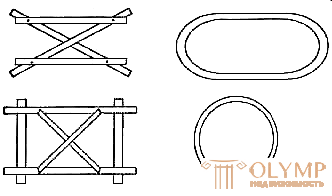

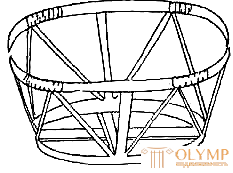

With the help of byugel (Fig. 7), the side racks (ribs) inserted into the finished bottom give the shape and position that is required from the product being manufactured. Having prepared the bottom of the basket, and securing all the rods-pillars forming the frame of the side walls, the weaver bends them up, puts the byugel on them of the required shape and size at a height corresponding to the height of the basket. The rack is tied to the byugel at regular intervals, and then proceed to braiding the posts with a rod or gloss, thus giving the basket a shape corresponding to the shape of the bugel. It is clear that the baskets, weaved on one byugel, are exactly the same in form. Bugeli made from hazel or thin willow stick. Byugel stock, as is evident from the destination, should be significant.

The template board is intended for weaving the bottoms of quadrangular baskets. Boards are made from linden or maple wood; their length is up to 60 cm, width is up to 25 cm. Several rows of holes are drilled in each board, positioning them so that each of them serves when weaving baskets of different sizes. Into the holes insert the stand of the base of the bottom of the basket and braid with a rod.

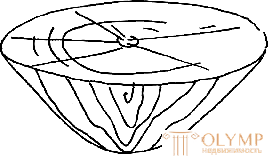

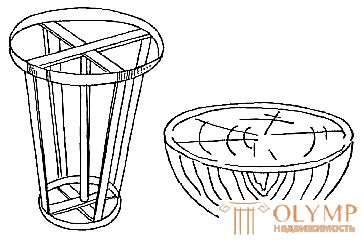

The template-pattern in form is an exact copy of the inner wall of the body of the product. It is used in the manufacture of various products. First, attach the bottom to it, and then to the last side racks. By pressing the side racks tightly to the body of the piece and braiding them, the weaver creates a piece that exactly matches the shape of the piece. Patterns are made from wood.

|  |  |  |

|  | ||

|  | Fig. 8. Patterns for weaving baskets | |

You can weave products and without a template, but for this you need to be a master of high qualification. The use of templates ensures the correct form and standardization of similar products, speeds up the manufacturing process, simplifies the work.

|

| Pattern for weaving vases, lamp shades, etc. |

Wedges are pointed pieces of hardwood, which, when weaving baskets with handles, are inserted in the place where the handles should be. The wedges are taken out of the finished baskets, and the ends of the handles are inserted into the nests remaining in their place, the latter should be sharpened. The wedge along its length must be such that when it is removed from the walls of the basket, it is possible to grasp its head. Some basket weavers do not use wedges; the holes for the handles are made with the help of a thick awl after finishing the weaving of the walls.

During operation, the moistened material is stored wrapped in plastic wrap, and the rod is also stored after work. It should be borne in mind that a moistened rod wrapped with plastic wrap cannot be stored in a warm room for a long time: it molds, becomes covered with black spots, blackens.

It is best to store the rod in a cold room in the cold. If there is no such possibility, then the soaked rods not used for the day can be left in a warm room, but without a film and not tied up in bunches, but freely laid out. Before work, the rods are soaked again until they reach the necessary flexibility.

Что бы оставить комментарий войдите

Комментарии (0)