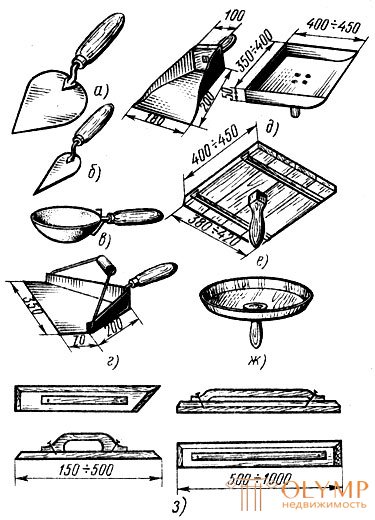

Tools for applying and leveling the solution (Fig. 9, a-h). The plastering blade (GOST 9533-81) consists of a steel cloth up to 1.5 mm thick, a handle with a knee 50 mm high and a wooden handle mounted on the handle. Blades are made with a blade length of 180 and 200 mm. The handle is fastened to the web by welding, less often it is riveted. Handles make one standard size. At the attachment points of the cutting, a solution accumulates on the web; it must be systematically cleaned. More comfortable are the paddles with a seamless cloth and a handle, since the solution is easily removed from them. The lighter the blade, the less tired the worker.

Fig. 9. Tools for applying and leveling mortar: a - plastering blade, b - cutting, c - ladle, d - scoop with a swinging handle, d - scoop-scapula and falcon-scoop, e - rectangular falcon, W - dish-shaped falcon, - poluterki

Plaster blades pour and approximately dispense various materials, mix dry mixtures and solutions, throw, smear, smooth, smooth, cut off solutions, clean tools, tools and accessories from the solution.

The cuts are small spatulas with thin steel blades 100, 125 and 140 mm long, 25, 35 and 56 mm wide. For some works, the fabric is shortened in length to 50 mm, in width to 10-15 mm. Apply cutoffs to clean the tool, cutting cracks in the plaster, grease, cutting and refilling the solution when cutting corners in rods, plastering.

The bucket for finishing works (GOST 7945-73) consists of a cup (ladle), a cutting, a wooden handle and a hook with which the bucket is hung on the side of the box. The total capacity of the bucket is 1.1 l, the working 0.8 l. Buckets are made of different metals, the most comfortable steel. Cups made of aluminum and various alloys are unsuitable because the solution strongly sticks to them, which reduces its slipping during sprinkling. Buckets are used to apply the solution on different surfaces and dispense materials.

Falcon is a shield made of wood or duralumin with a handle in the middle. From the falcon, the solution is applied to the surface with a spatula or directly applied with a falcon and spread on the surface.

Wooden shield is made from three to four 10-15 mm boards. The boards are fastened together with keys with dovetail groove or nails. The key should protrude 15–25 mm above the shield plane. It prevents the shield from warping and serves as a stop for the end of the scapula when spreading or leveling the mortar. Double handle spikes should be 1-2 mm below the shield plane. This is necessary so that the blade does not cling to the spike handle. The shield can also be made from 8-10 mm plywood on waterproof adhesives, but you also need to nail the keys to it. Falcon shield is saturated with linseed oil and dried. Wood falcons should have a smooth, smooth shield. They are convenient because they do not stick to them and the solution is easily cleaned from them.

Duralic falcons are light, but a solution sticks to them, and this delays the sliding of the blade on the web. In addition, it does not have keys that would serve as a stop for the end of the blade when spreading and leveling the solution with a falcon. The end of the scapula may slip off the leaf and injure the arm. It is not always convenient to press the falcon with the hand or the handle of the plastering blade. Some plasterers put a rubber cap on the blade handle and the handle slips less on the metal. However, focusing the end of the blade is more convenient, since the blade does not have to be turned over. It is best to rivet the tabs on the falcon shield.

To hold a large portion of decorative or liquid conventional solutions, dish-shaped falcons are manufactured, square or round, with a handle in the middle or side.

Pawns are made of linen and pen. They are made from not knotted wood. Depending on the purpose, they come with a web 150-2000 mm long, 20-150 mm wide, 5-30 mm thick. Cloth smoothly planed, and best of all fugovano. Semi-graters are used for leveling, smearing mortar, rubbing architectural elements.

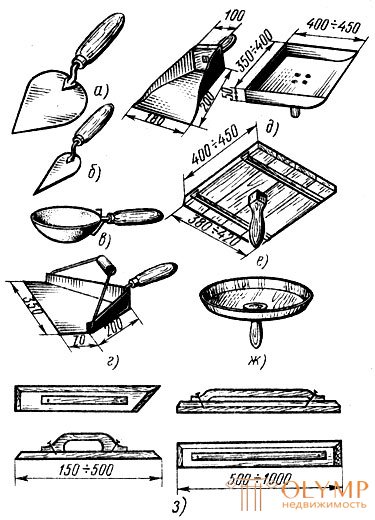

Fig. 10. Tools for finishing the plaster: a - a wooden grater, b - a universal metal grater for attaching felt, c - a universal metal grater for fastening wooden cloth, d - trowels, d - a brush (okamelok), e - bushda, w - a chisel, h - trojan and zubchatka, and - shaped semi-graters, k - steel brush, l - cycle, m - nail brush, n - plaster ruler, o - rustication

When wetted and dried, the grater webbels warp and begins to rub over some part, which reduces productivity. If a dense felt or felt is nailed to the canvas, such a grater wipes a cleaner, but does not cut off small tubercles. Therefore, first rub the surface with a float with a wooden sheet, and then with a padded felt.

The brush is intended for wetting surfaces with water and dried plaster, washing tools and other purposes. Brushes come in different sizes and shapes, from hair, sea grass, bast. In plastering works, brushes are often used, which were used by painters and not suitable for painting - pellets.

Buchard - a metal hammer weighing up to 1.5 kg. On the front sides of the bouchard there are notched from 16 to 36 pyramidal teeth. Instead of teeth, there may be cutting in the form of straight blades. When machining surfaces on the latter, they remain from the teeth of the fossa, from the blades - stripes (strokes). Bouchards are used for forging decorative plaster on a cement binder (stone and terra-site) and for preparing stone, brick, concrete and similar surfaces.

Chisels are used to select the seams in the masonry, notching decorative plaster, preparing surfaces.

Trojan and Zubchatka are used for the same purpose as chisels. The trojan has three teeth on the blade, and the teeth on the blade have several. They make chisels, trojans and teeth from steel.

Shaped trowels - metal 804 mm long and wooden up to 2000 mm long are used for polishing husks, whiskers and chamfers.

In wooden semi-ceilings, the canvas is knocked out of two planed boards at a right angle. The handles to such poluterkam fasten, as well as to the usual, nails. The lack of wooden trowels in the fact that, wetting and drying out, they jarred on.

Steel brushes (wooden handles into which steel wire is inserted) are intended for cleaning various surfaces, cleaning some types of decorative plaster.

Cycles (GOST 12378-81) - steel plates up to 200 mm long with teeth of different height and width. This tool is used for copying decorative plasters, especially terrazitic ones.

Nail brush - a piece of board or a grater with nails stuffed into a cloth, the ends of which protrude 3-10 mm from the plane of the board, depending on what size the texture should be obtained. Nails are stuffed at a distance of 5 to 10 mm in rows or in a checkerboard pattern. Brushes used for processing terrazitovye plasters.

Plastering line is used for cutting corners, raskrepovok, ie, cutting the solution applied above the level of thrust. Rulers are made of wood. Their length, thickness, and width vary. A long line is more convenient for work, as it provides a more accurate cut of the solution. One or two ends of the ruler are cut at an angle of 45 ° and the steel cutter is nailed on the same level with the working plane of the ruler. The edge of the ruler can be flat - for cutting rectangular architectural breaks or rounded - for cutting curvilinear break-offs.

Rustovka - wooden or metal semi-graters with a length of 300-400 mm with a notch at the end and an attached steel strip in the form of a semicircle, which is a cutter and serves to cut the solution between the floor slabs.

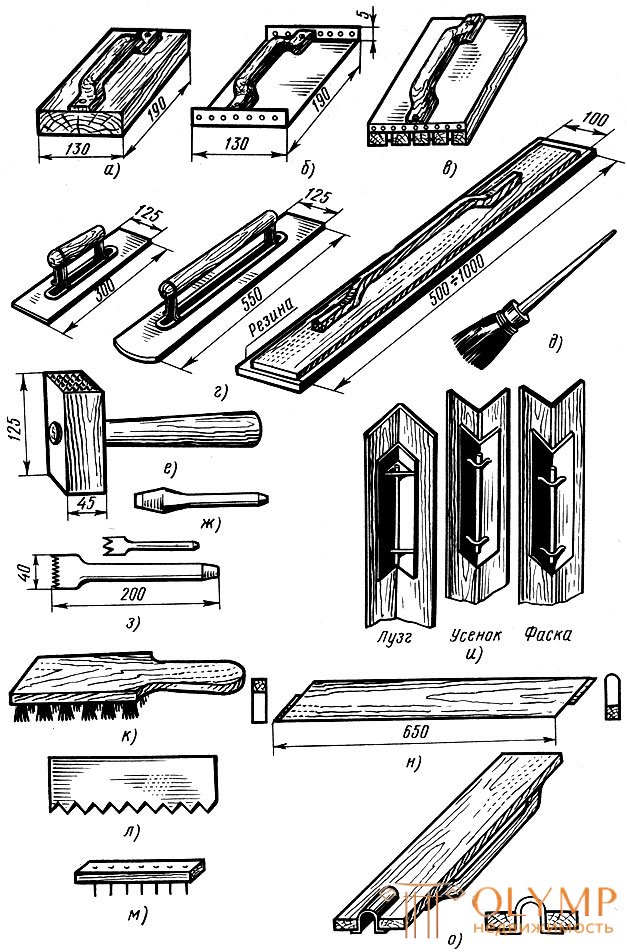

Tools for preparing and testing surfaces (Fig. 11, a-i). A plaster hammer at one end has a pickaxe measuring 25 x 25 mm, on the other - curved horns with slots for pulling nails. The hammer sits on a 300 mm long handle. The weight of the hammer (450-475 g) and the handles are designed so that you can hammer plaster nails in two strokes.

Fig. 11. Tools for preparing and checking surfaces: a - plaster hammer, b - cam, c - plaster knife, g - scissors for cutting metal, d - plumb, e - level, f - water level, h - water level, and - gon with slide bar

A cam is a hammer with a wide edge weighing from 1 to 1.5 kg. It is used to strike on the chisel, trojan, zubchatka.

Scissors for cutting metal is used for cutting steel profiles to templates, cutting the grid. Scissors with curved handles are more convenient and safe in work. When working with such scissors, the hands are always above the cut edges of the mesh, which reduces the risk of injury.

A plumb bob is used to hang surfaces and check their horizontal position. It consists of a load and a cord. Plumb weight in the form of a cylinder with a pointed end weighing at least 200 g. The diameter of the cargo is 10-20 mm, which makes it possible to hang surfaces for plaster with a thickness of 5 mm or more. Cord length 20 m.

Levels are used to check the vertical and horizontal surfaces, they are of different lengths, wooden and metal, with one or two reticle. Levels should be prevented from falling, as they may break or their viziers move.

Plumb-rake is the simplest wooden level of two slats set at right angles to each other. Short slats-plumb lines have a length of 600-750 mm, an average length of 1000-1500 mm. Plunge racks are simple - only for checking vertical surfaces and combined ones - for checking vertical and horizontal surfaces. A simple plumb rake is a fugated board, in the middle of which a risk is held or studs are hammered and a plumb line is strengthened. Combined slats-plumbs consist of two strips: long and short, which is attached to the long at an angle of 90 ° with a spike and struts. In the middle of the rails carry risks at the intersection of which drive a nail and attach a plumb line. Usually at the ends of the rails on the risks of driving studs, which check the position of the cord. For storage of a plumb in the corner between the slats arrange a box.

The flexible level is used for hanging horizontal surfaces or punching horizontal lines on the walls. This level consists of a rubber tube 10-15 mm thick of the required length. In the ends of the rubber tube are inserted glass tubes with a length from 200 to 300 mm with graduations. If the level is filled with water and the tubes are brought closer to each other on the same level, then the poured water should stand on the same divisions.

Squares are wooden and metal, preferably with a mobile bar, with which it is easier to measure the angles of dawn slopes. Their sizes are different. Squares are needed for marking, checking raskrepovki, corners, making profiled boards.

In addition to the considered tools for plastering work, saw, ax, meter, wire cutters, tongs, files, bars, etc. are also used .

Tool attachment and care . All tools must be firmly seated on the handles so that they cannot come off during operation. This is especially true for percussion instruments: hammers, cams, bushards.

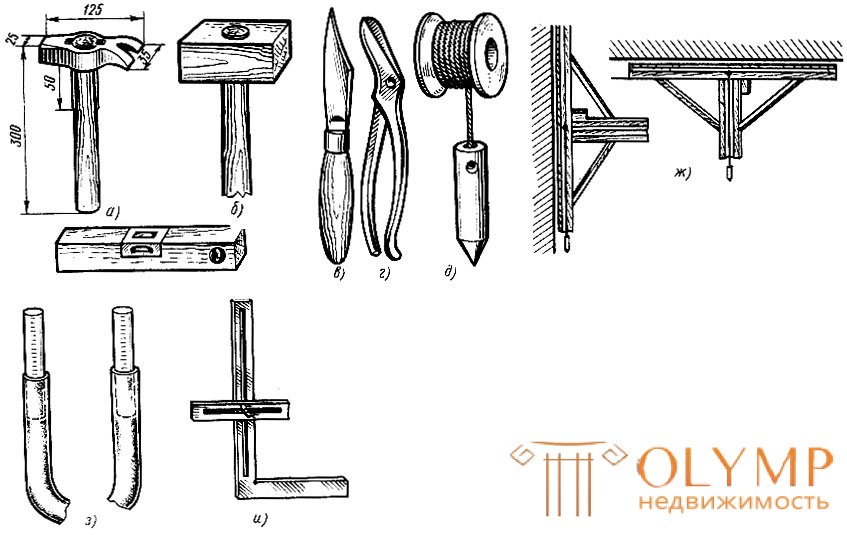

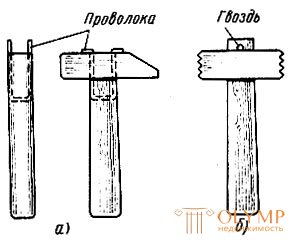

Hammers and cams (Fig. 12) are first pushed onto the handle so that they stop moving on it. After that, a hammer or cam is seated, the end of the handle is cut off, a hole of diameters of 5-7 mm is drilled at a distance of 50-100 mm from this end, and grooves are cut from it on two opposite sides along the thickness of the wire used. Then they insert a piece of wire into the hole, fold it so that it fits tightly into the grooves, and cut off the ends so that they protrude from behind the handle by 10-15 mm. A hammer or cam is put on the handle, pushed in, bent over the ejected ends and wedged. The ends of the wire firmly hold the tool.

Fig. 12. Nozzle of percussion instruments: a - a hammer and a cam, b - boochards

Buchards are best fixed using wedges and nails to hammer into the handle, but across the hole. In this case, the end of the handle should protrude 20-30 mm behind the bouchard.

The handles of all tools are recommended to be well cleaned and coated with linseed for one or two times. They are less wet and easy to clean from the solution.

After work, the instrument is inspected, cleaned of the solution and, if necessary, washed. The burrs are chipped off or grinded. If this is not done, then, breaking off and flying away, they can cause damage.

While working with percussion instruments, pieces of material fly away from the surface to be treated, therefore plasterer should be in protective glasses and mittens.

Что бы оставить комментарий войдите

Комментарии (0)