For fixing drywall is most effective to use screws that attach it to the metal frame. For screwing screws can be used shaped screwdriver, if the amount of work is very small. If you need to work a lot, you should use a screwdriver. Moreover, this tool is unthinkable without its important part, which is called a bat. With its help, it will be transferred from the tool to the screw.

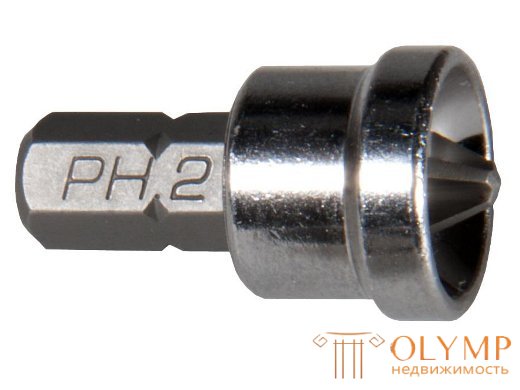

For even more convenience, a drywall bit with a limiter is used. But first, let's look at what a regular bit is.

The limiter does not allow the tip of the bits to fall below a predetermined level

Content:

Imagine an ordinary hexagon 5 cm long. One end of it is attached to a screwdriver, and the other end has the shape of a screwdriver tip. This is a bit. For repair work in the apartment bits are used, which are divided into:

Cross bit is what you need to work with drywall

The two most popular standards are PH and PZ. Bits on the screwdriver for drywall with PH classification are considered universal. The shape of the head is specially designed so as to increase the area of adhesion with the screw, which in turn leads to the fact that the load is evenly distributed. As a result - the screw easily passes through the drywall and the metal profile. You can not be afraid that the slots will be broken. Usually use the size number 2.

Ratio of the number of bits and thread fasteners

The second most popular standard PZ has an additional four small diagonal edges. As a result, it is possible to achieve even an even larger area of coupling than the PH-bit. However, it is hardly advisable to use them when working with GCR, because they are more suitable for working with rigid materials. They are also good if you need to unscrew the screw that stuck. The most running are the second and third numbers.

To understand why bits are used on a drywall screwdriver, it’s enough to think about the time and effort that is spent manually screwing in the screws.

A good bit is mainly made from chrome-vanadium. You need to carefully look at the products that are brought from China. If you miss this moment, then by the middle of the work, the sting of a bit may start to wear out due to the fact that it is made of bad steel.

PH and PZ (Phillips and Pozidriv) are standards for cross bits. There are other standards (Slotted, Hex, Torx, Robertson, Tri-Wing, etc.), but they do not apply when working with drywall, so there is no point in considering them.

It is not enough to simply attach the GCR to the frame. You need to do this so that all fasteners are flush with drywall. In other words, screws should not stick over the surface of the sheet. This will ruin all further work with the surface. In particular, it will be impossible to putty drywall. However, you can not mindlessly twist the screw as deep as possible. He must enter the drywall just enough to not hang around with it. This will help bits for drywall with a limiter.

The material from which the limiter is made does not play a special role.

On the screwdriver, you can set the torque. If the screw is not screwed, then we make more torque, if the drywall breaks, then less. Thus, it is possible to control the force with which the screw will be twisted. However, it may take a long time for a repair beginner to find the right value. Moreover, it is difficult to do, because one effort is needed for rolling drywall, and to go through a profile is quite another. Moreover, the screws have different sharpening and they cut the profile with different force. Therefore, it is recommended to use a bit with a limiter, because it has certain advantages.

In fact, it should already be clear how the bits for the drywall screwdriver are selected. Since all the screws come with a cross-shaped cap, then you need to take the corresponding bit with the limiter. As previously stated, these are the PH and PZ standards. Always take the second number, because it is suitable for working with screws, whose diameter is 3.5 mm. These are the screws used in the installation of drywall. Their length can be 25 mm, 35 mm or even 45 mm, but the diameter is always 3.5 mm.

When choosing, pay attention to the bit length. If designs with shelves and niches are created, then you may have to work in slightly uncomfortable conditions, because of which a long bit will be useful.

It looks like a screw, twisted by a bat with a limiter

On brands you can not navigate, you still do not know them. And the knowledge of what Toptul is doing in Taiwan, Stanley in the USA, GROSS in Germany, and Sigma with VEKO in China, will not give you anything. But what is worth thinking about is the material. If the bat is made of incomprehensible steel, then its quality is in doubt.

There are several alloys that are considered most suitable for making bits for drywall with a limiter. Chromium and vanadium, tungsten and molybdenum, chromium and molybdenum - these are the highest quality alloys. If a bit with a limiter is useful for more than one repair, then it should be made from any of these alloys.

The presence of a magnet in a bit with a limiter will allow you to attach screws to it and do not hold them with your hands. Such a little trick greatly speeds up the workflow.

In addition to the material of the bat, you should pay attention to its protective coating. What can such coatings be made of and why are they needed?

Что бы оставить комментарий войдите

Комментарии (0)