Carcass and wicker furniture frames are assembled on nails or screws (screws) from straight and bent parts. Immediately we say that the preparation of parts by hand does not guarantee the correctness of their configuration and dimensional accuracy, which often leads to damage to the surfaces by the jacks. The use of templates in the preparation of parts makes it possible to give them the required dimensions, standard shape and a surface that does not have any damage. In addition, when preparing bent parts on templates, work moves much faster.

When the closed frames of the seats are annular, trapezoidal, oval and others, the parts get the right shape on the outside, but their slight irregularity on the inside does not affect the quality of the product.

The fastening of the ends of the bent parts by the method "on the mustache" on the template eliminates deviations in size when they are fastened by eye. There is another advantage of making bent parts on the templates - the marking of their attachment points during assembly of the frames can be performed on the template, which ensures the correctness of their placement in the finished product and speeds up the process of assembly of the frames.

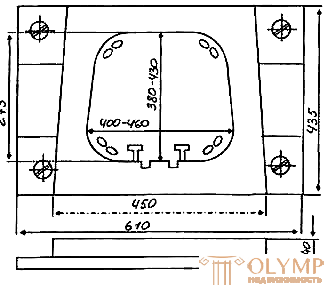

When bending ring parts using a template that is made of pine boards. The bending procedure is performed along the inner cut, for which the butt-cut end of the stick is placed between the abutment of the template, after which it is bent along the inner cut. Further, the opposite end of the stick is cut off “on the side” and the joint is fastened with nails (Fig. 1, 2).

| Template for bending ring parts |

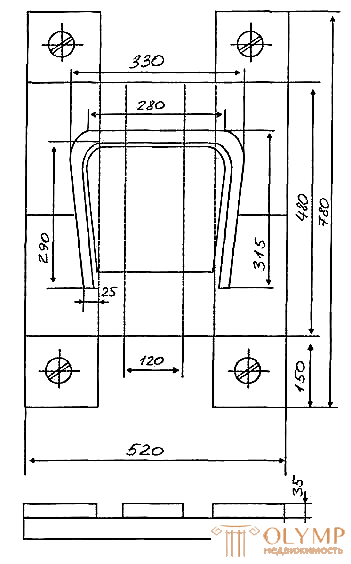

| Template for bending the backrest of chairs and armchairs |

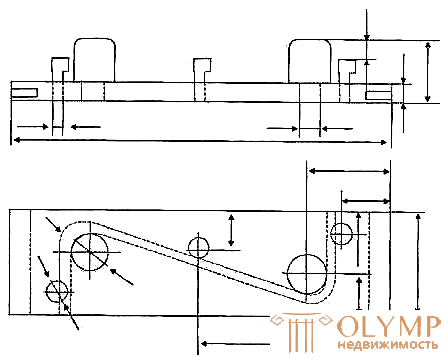

| Patterns for bending armrests |

| Patterns for bending sofa backs |

In the same way, a template is prepared for bending trapezoid and other closed parts. Unclosed parts (armrests, bows for the decoration of the backs, various inserts, back arches, etc.) are made using templates of a different design, on which bending is carried out using stops placed on the basis of the template (Fig. 3).

At the ends of these supports there are holes for attaching the template with screws or bolts to a wooden frame. An oval-shaped plank is attached to the middle longitudinal stand, designed to serve as the base of the upper board of the template with an arc of the backrest.

The procedure of bending the backrest arc consists in the following: with trapezoidal details, the butt end of the willow stick is equal to a knife or shears and is inserted into the left gap formed by the template board; after that, bend the stick on the upper board of the template and cut off the other end of it in such a way that it fits tightly enough into the gap that forms on the right side of the template board. You can also make special patterns for bending the bow of the backs of chairs, armrests of chairs and sofas, backs of sofas.

The parts bent on the template are dried, in order to avoid deformation they are placed on special racks, on which there are limiting racks and sockets corresponding to the configuration of this part. After completing the drying on the parts, they smooth out irregularities, bumps and other defects.

The front parts, which are not subjected to further wrapping with willow ribbons, are sanded manually or used for this purpose. The assembly of the projectile into the lock is best done on a template with slotted grooves in which the projectile parts are laid. In the middle part of the template, a hole is provided for the free passage of the nail, fastening the lock joint of the archways.

Что бы оставить комментарий войдите

Комментарии (0)