5.1. Types of line measurements

Measurements of lines on the ground can be performed directly, by putting aside a measuring instrument at the site of the measured line, with the help of special devices of range finders and indirectly. An indirect method is used to measure auxiliary parameters (angles, bases), and the length is calculated by the formulas.

5.2. Devices for direct measurement of lines

To measure the lengths of the lines by means of laying off a measuring device, steel measuring tapes are used, which are usually made of carbon steel tape. In geodetic practice, most often used bar and scale ribbons.

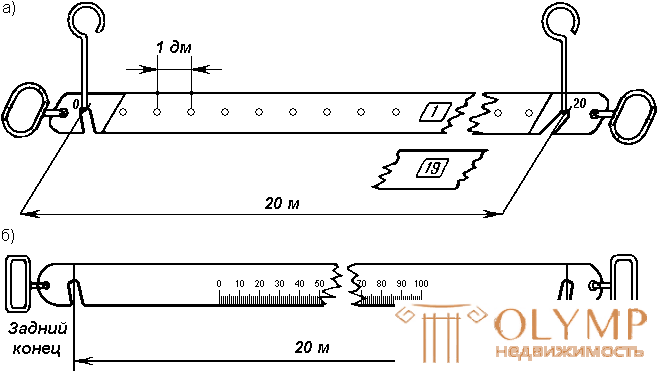

Dashed ribbons (Fig. 47a) are 20 and 24 m long, 15–20 mm wide, and 0.3–0.4 mm thick.

Fig. 47. Measuring tapes.

On the tape are marked meter divisions, indicated by attached plaques, and decimeter divisions, indicated by holes. Meter divisions on both sides digitized. The counting digitization account is conducted on one side from one end of the tape, and on the other from the other end. For the length of the tape take the distance between the strokes deposited on the hooks at the ends of the tape. Handles are attached to the hooks. The tape is attached 6 or 11 studs on the ring. The studs are made of steel wire with a diameter of 5 - 6 mm and a length of 30 - 40 cm in the off position the tape is wound on a ring (Fig. 47, c).

Scale tape (Fig.47, b) is produced with a length of 20 - 24 m, a width of 6 - 10 mm and a thickness of 0.15 - 0, 20 mm. At both ends of the tape, within the second decimeter, there are millimeter scales with a length of 100 mm each.

Steel and tape roulettes 5, 10, 20, 50 m long are used to measure small distances. The divisions on the tape measures are applied on one side in 1 cm and rarely in 1 mm. The rolled tape measure is placed in a metal or plastic case.

5.3. Comparing tapes and roulettes

Measuring tapes and tape measures before measuring lines should be checked. This test is called comparing and consists in determining the actual length of the measuring instrument by comparing it with a reference instrument, the length of which is precisely known.

For the purpose of comparing bar tapes for an exemplary measuring device, one of the tapes available in production is taken, the length of which is checked in the laboratory of the State Supervision of Standards and Measuring Techniques of the State Committee of Standards of the Russian Federation and used in comparison with working tapes. Scaling ribbons are produced on special devices, called stationary comparators.

The simplest way of comparing stroke tapes is as follows. On a horizontal surface, for example, on the floor, lay a model tape. Next to it, put the tested tape so that their edges touch each other, and zero strokes are combined. By firmly fastening the ends with zero strokes, the tapes stretch with the same force and measure the difference between the final touches at the other ends of the tapes with a millimeter ruler. This value indicates how many millimeters the working tape is shorter or longer than the model tape and is called the correction for comparing Δℓ.

The length of the tested 20-meter tape shall not differ from the length of the model tape by more than ± 2 mm. Otherwise, corrections are introduced into the measurement results of the lines. At the same time, when measuring the lines with a working tape, it is believed that its length is equal to 20 m. Amendments are determined by the formula

where D is the length of the measured line.

The correction is subtracted from the measurement results when the working tape is shorter than the model tape, and added when it is longer.

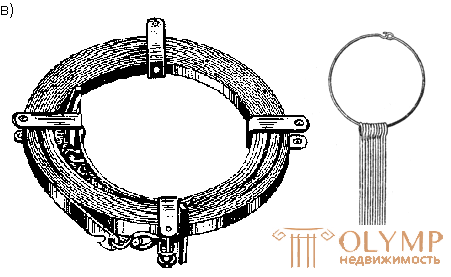

5 .4. Hanging lines

A straight line on the ground is usually designated by two milestones installed at its ends. If the length of the line exceeds 100 m or on some parts of it the installed milestones are not visible, then for the purpose of convenience and to increase the accuracy of measuring its length, additional milestones are used. They are installed in an imaginary plumb plane passing through this line. This plane is called the alignment line. Installing milestones on the target of this line is called hanging (fig. 48).

Fig. 48. Hanging line

Hanging lines can be made by eye, using field binoculars or instrument telescope. Hangings usually lead to themselves. The observer becomes on the hanging line at the milestone A (Fig. 48), and the worker, at his direction, places the milestone at point C so that it covers the milestone B. In the same way, milestones are installed at points D and E. Reverse milestones (from itself), is less accurate, as previously exposed milestones close visibility to the next. More precisely, milestones on the target are set according to the theodolite installed at point A and oriented towards milestone B.

5.5. The order of measurement lines dashed tape

The measurement of lines on the ground by dashed ribbons is made by two workers. In the direction of measurement, one of them is considered the rear, the second - the front. Tape neatly unwound from the ring. Its digitization should increase during the measurement. For fastening the measuring tape in the line of the line 6 pins are used. Before starting the measurement, 5 studs are taken by the front gauge and one by the rear. The rear gauge combines the zero line of the tape with the beginning of the line. Using a slot in the ribbon, fastens the end of it with a pin next to the peg, which marks the starting point of the line (fig. 49, a).

The front puller, having 5 studs in his hand, at the direction of the rear puller, shook the tape, tightens it in the line of the line and fixes the front end of the tape with the first stud. Then the rear gauge pulls his stud out of the ground, hangs it on the ring, and both scoopers carry the tape forward along the line. Having reached the stud stuck into the ground with a front splicer, the back sprocket fastens its end of the tape on it, and the front end, having pulled the tape, fixes its front end with the next hairpin (fig. 49, b). In this order, the gauges lay the tape in line with the line 5 times.

After the front measurer fixes his end of the tape with the fifth stud, the rear measurer gives him a ring with five studs, which he assembled during the measurement (fig. 49, c). The number of such transmissions (ie, segments of 100 m with a tape length of 20 m) is recorded in the measurement log. The last measured residual line is usually less than the full length of the tape. When determining its length, meters and decimeters are counted on the tape, and centimeters are evaluated by eye (Fig. 49, f).

Fig. 49. Line measurement by measuring tape

The measured length of the line D is calculated by the formula:

D = 100 · a + 20 · b + c,

where a - the number of gear studs;

b is the number of studs at the rear gauge on the ring;

c is the remainder.

To control the line is measured again the 24-meter or the same 20-meter in the opposite direction. The arithmetic average of the two measurements is taken as the final result, if their discrepancy does not exceed:

- 1/3000 parts of the line length under favorable measurement conditions;

- 1/2000 - average measurement conditions;

- 1/1000 - adverse measurement conditions.

Those. absolute errors per 100 m of the line length of 3 cm, 5 cm and 10 cm are allowed.

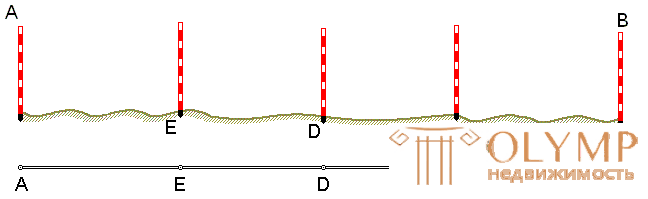

5.6. Calculation of the horizontal projection of the sloping terrain line

When creating local plans, the horizontal projection of each line is calculated, i.e. its horizontal positioning is S.

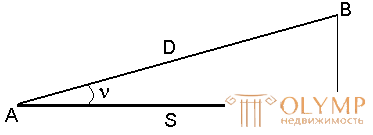

Fig. 50. Horizontal projection of the line

If the line AB (fig. 50) is inclined to the horizon at an angle ν , then the horizontal distance can be determined using the formula

,

,

where D is the length of the measured inclined line AB; ν is the angle of inclination.

Sometimes, the slope correction is used to determine the horizontal distance.

,

,

then

.

.

The slope correction is entered at slope angles greater than 1 °. Tilt angles are measured by theodolite.

5.7. Indirect line length measurements

When measuring distances with a tape or tape measure, there are cases when a local obstacle (river, ravine, building, road, etc.) makes direct measurement impossible. Then apply indirect methods for determining distances.

There are three cases of determining inaccessible distances.

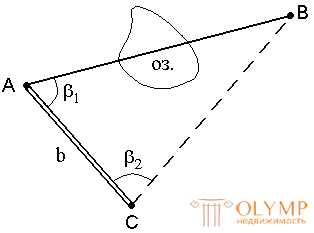

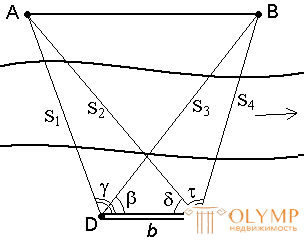

1. When points are visible, the basis b is broken and the horizontal angles are measured.  and

and  (Fig. 51).

(Fig. 51).

Fig. 51. Indirect distance measurement across the lake

To determine the distance AB, the sine theorem is used.

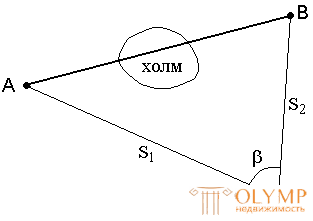

2. When points are mutually invisible (fig. 52), point C is selected from which points A and B are visible, measure distances S1, S2 and angle  .

.

Fig. 52. Indirect distance measurement through

Using the cosine theorem, find the distance AB

.

.

3. If both points of the measured distance are not available, then break the basis b and measure the angles from points C and D

Fig. 53. Indirect measurement of distances if both points are not available.

According to the sine theorem, the distance AB is found twice for control with control.

|  |

|  |

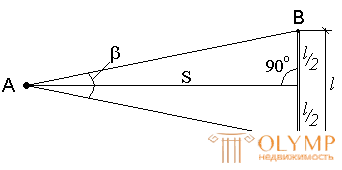

5.8. Parallactic method of measuring distances

This method is based on the solution of the triangle ABC, in which to determine the distance SC with high accuracy, the small side l , called the basis, and the acute parallax of it acute acute parallactic angle, measured perpendicular to the measured line  (fig. 54). The distance S is calculated by the formula

(fig. 54). The distance S is calculated by the formula

Fig. 54. Parallactic method of measuring distances.

By measuring the distance in this way, a horizontal distance is obtained immediately, so the introduction of corrections for the slope of the line is not required.

5.9. Questions for self-control

1. What is called line hanging?

2. What is the target line?

3. What instruments are used for direct measurement of distances?

4. What is the comparison of measuring devices?

5. How are the lines measured with steel measuring tape?

6. How are the inclined distances to the horizon?

7. What determines the accuracy of the measurement line measuring tape?

Что бы оставить комментарий войдите

Комментарии (0)