Upholstered furniture frames are assembled from structural units using all kinds of connections. Structural details of which make upholstered furniture frames can be divided into parts (bars) made of solid wood, glued from plates, bent and plates - joinery, fiber, chipboard, plywood. The main structural details are connected in knots (frames and boxes), from which the seats, backrests and armrests are then assembled.

Rama . Frames are widely used in furniture designs. They are used as a base for pillows in ottomans, couches, sofas, in solid and overhead seats of chairs, armchairs, stools, armchairs, sofas, in the backs and armrests of chairs, armchairs, sofas. Frames are usually made from solid wood, both coniferous and hardwood, mainly from pine and beech.

The boxes . One of the structural units are boxes. Like the frame, they are the main structural components of furniture frames. They are used in the seats of chairs, armchairs, stools, sofas. Boxes for chairs and stools are usually made of solid wood, beech or pine, as well as veneered. For the manufacture of boxes of armchairs, combined furniture, sofas, and chaise longues, usually solid wood or slabs are used. Boxes ottomans, and sometimes also chairs and sofas are assembled from wide elements. Sometimes frame constructions are used here, the frames in these cases are filled with fiber plates or plywood and immediately upholstered with facing fabric.

Armrests . Armrests suit at chairs, armchairs, sofas, armchairs, beds. In ordinary chairs, armrests are made stiff, in more comfortable furniture - partly soft. The armrests in the upholstered furniture can be of various designs:

Armrests are made from solid hardwood, made from coniferous wood, veneered.

Backrest . The backs are made in chairs, armchairs, sofas. They are made from solid wood or from slabs. There are many different designs of backs, of which the following should be highlighted:

the back representing a uniform design with a back leg;

a separate back, then connected to the rear legs or frame, for example, in sofas and armchairs; lateral back of an ottoman, couch.

Ways of connections . For the assembly of wooden elements in the nodes and frames used various compounds. Assembly of parts, as already mentioned, is very important, especially in the manufacture of upholstered furniture, intended for frequent use. The following are the most commonly used methods for joining joinery parts.

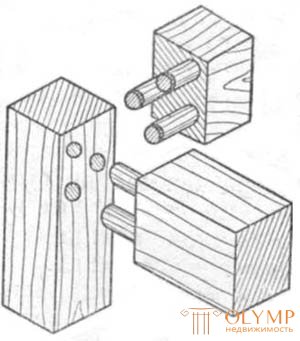

One of the oldest methods is to connect with round spikes. The base is a dowel, made of solid dry wood without knots with a smooth or carved surface, set on glue in a nest pre-selected in the part element.

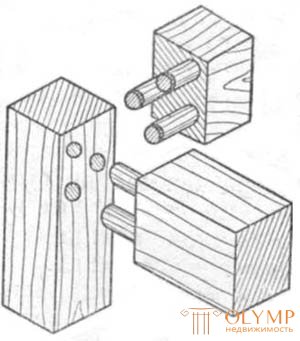

The connection on round spikes is used in the middle knitting, in the longitudinal or at an angle assembly, as well as in all cases where the use of other types of compounds is associated with structural or technological difficulties. To increase the strength of a joint when using several round spikes in it, they are not placed on a straight line, but with ledges (Fig. 1). Round spikes can be of different diameters and heights, depending on design requirements. In some cases, round spikes cannot be replaced by other compounds, in particular, when frilling bent parts (Fig. 2).

|  |

| Fig. 1. Methods for placing round spikes | Fig. 2. Knitting curved bars (the use of straight spikes would weaken the binding) |

For knitting elements into the frame use several types of connections on round spikes: on a straight joint, on a beveled joint, patch joint. Straight joint is used in cases where the frame must be studded entirely, in frames of small size and in profiled frames, where the spike could go through. Oblique joint is used in cases where the frame is not fully upholstered and is finished in a joinery way, as well as in small frames.

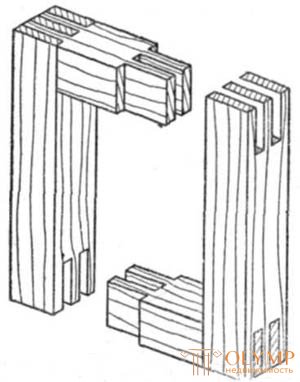

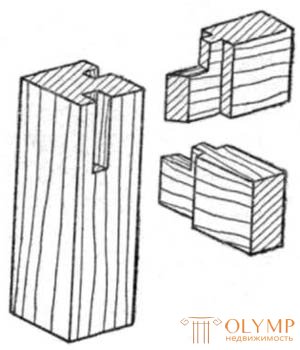

Another type of connection in frame structures are connections on flat spikes. They are used everywhere, as they are easy to manufacture in factories. This type of joint is very durable, especially through the spike, which has the largest bonding surface.

The most common types of connections on flat spikes:

The connection to the open straight spike is one of the strongest, thanks to the large bonding surface. This method connects the large frame size.

The double open spike is even more durable. It is used when knitting even thicker parts.

Deaf thorny joints are used in cases where it is necessary to cover the head of the spike, in cases where some part of the surface of the frame is not upholstered. When assembling a secret spike eliminates the need for additional lateral crimping of the frame, which is necessary when knitting in other ways. However, this is an uneconomical method, since it is necessary to increase the width of the frame bars in order to avoid splitting off the ends of the bars during the gluing process. On the closed spike, the parts are tied when the frame remains visible in the finished product. This is a very fragile connection.

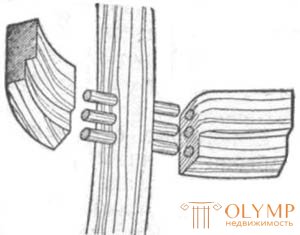

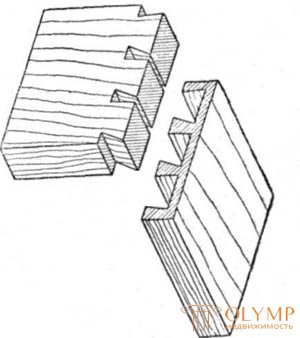

Connections on the tongue are applied in straight frames; in the profiled frames there are mainly round spiked joints. The types of connections when assembling boxes can be divided into connections for direct knitting of these knots and for knitting with simultaneous connection of the legs of this piece of furniture.

The first group includes the following types of compounds: Round spiked, used mainly in the binding of elements or nodes of solid wood; This type of connection ensures uniform drying of the connected elements. Knitting can be reinforced with additional stickers in the corners.

|  |

| Fig. 3. Tying the frame with a double straight spike. | Fig. 4. Tying the box on the mustache on the plug rail |

Sheet piling, found when joining woodpieces, especially veneered (Fig. 4). For strength make stickers in the corners.

Direct box, very strong connections, but used only in cases where the box is upholstered. Spiked connections in the semi-light (Fig. 5) bind the details in cases where the node remains on the one hand not upholstered.

|  |

| Fig. 5. Tied with a half-open spike | Fig. 6. Knitting a box with a semi-thin thorn |

In the second group, various compounds are usually applied on round spikes and on flat ones (Fig. 6).

In addition to the methods discussed, there are also connections using screws, screws, bolts, or other special metal products. Metal compounds are used mainly in the manufacture of combined furniture.

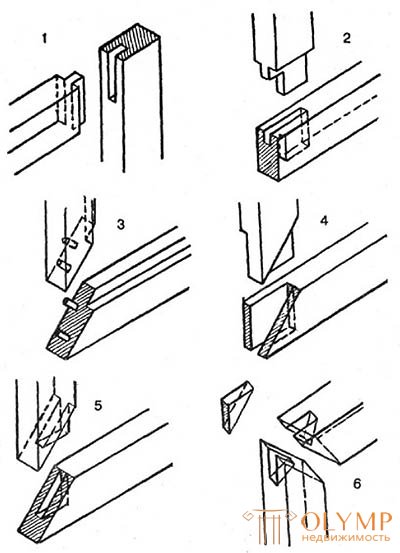

|  |

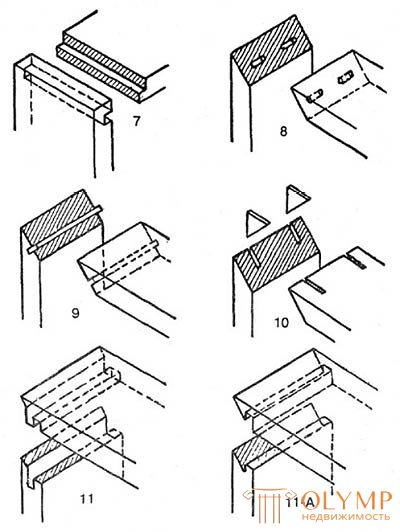

| Joiner's connections: 1 - a deaf open unary thorn; 2 - deaf single spike half-full; 3 - on the side of the plug-in round spikes; 4 - with a one-sided open spike; 5 - on a mustache with a deaf, secret spike; 6 - on the mustache insert thorn | Joiner's connections: 7 - butt on the whole thorn; 8 - on the mustache round plug-in studs; 9 - on the side of the insert key; 10 - on the side of the plug-in flat spikes; 11 —11A — on a full thorn |

|  |

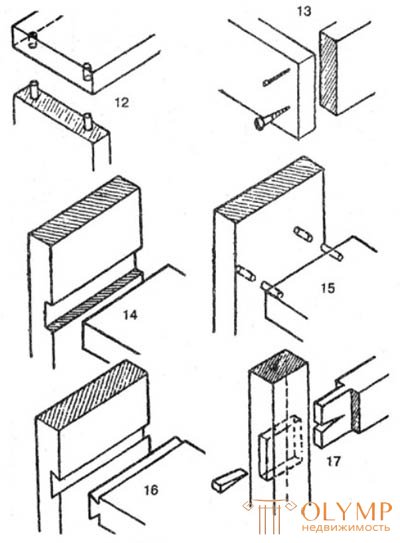

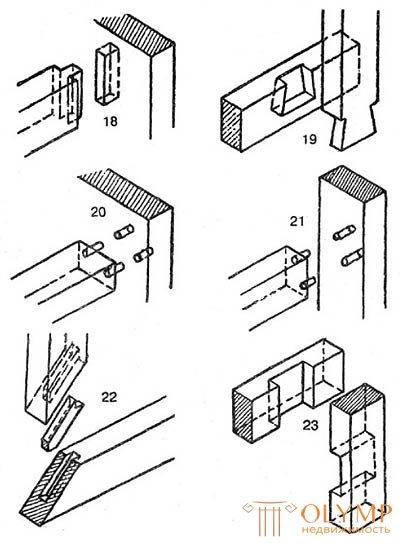

| Joiner's connections: 12 - on plug-in round spikes; 13 - metal pins or screws; 14 - in a wide groove; 15 - plug-in round spikes; 16 - in reward bilateral; 17 - straight single through spike with splitting | Joiner's connections: 18 - a straight single unvoiced thorn; 19 - deaf pan; 20 - round insert spikes; 21 - round insert spikes; 22 - flattened barb; 23 - mating of rectangular section bars in half-tree |

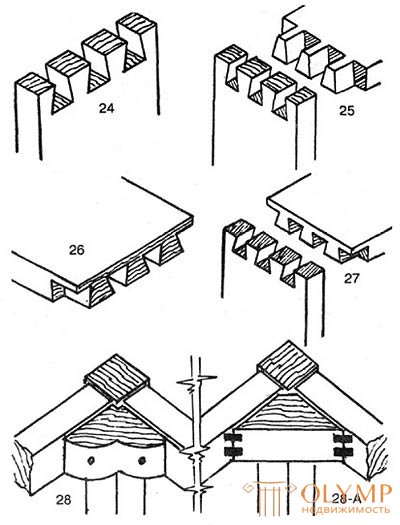

| Joiner's connections: 24 - dovetail thorn; 25 - dovetail spike open; 26 - half-dovetail thorn; 27 - a half-dove spike; 28 - 28А - connection on bosses |

Что бы оставить комментарий войдите

Комментарии (0)