Using drywall in repair work, invariably have to deal with the creation of the frame. Often use guides, rack and ceiling profiles, but sometimes you can do only one type. Profiles vary in their configuration, size and section. We consider the guides for drywall, because they are used most often.

Often, creating a simple structure of plasterboard, you can do only one guide to create a frame. It is clear that if you do interior partitions and other massive structures, you will need to use additional types of profile.

Content:

To create a new design and new surfaces were smooth and as you want, use the frame, which sheathe plasterboard. Galvanized profiles can be cut and curved at will, creating any elements . After plasterboard sheeting you can get beautiful shelves, cabinets, TV stands, arches, shelves, etc.

Framework for a multi-level ceiling from metal profiles

The following profiles are commonly used:

wall guides. Such guides for drywall denoted by the symbols Mon or UW. They are used to create a wall frame;

wall guides. Such guides for drywall denoted by the symbols Mon or UW. They are used to create a wall frame; Previously, for such purposes used wooden crates. But the use of bars and slats is a thing of the past. Profiles have won the market due to the following advantages:

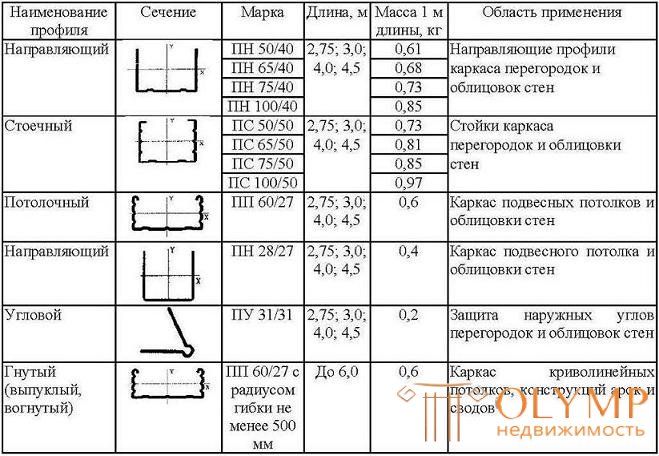

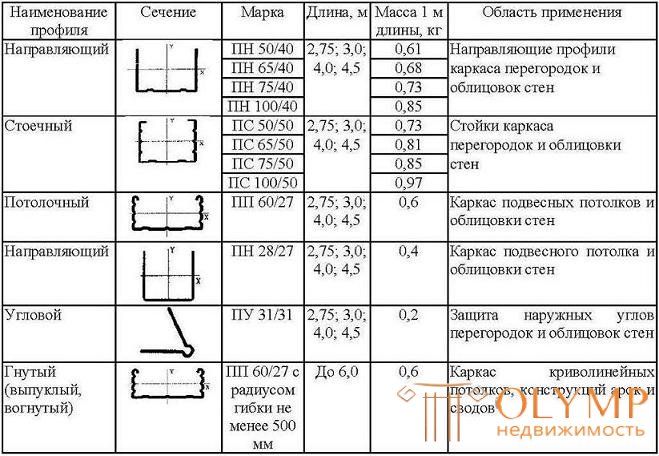

The size of the profile affects the entire workflow, because you need to know in advance what materials are available. The guide profile for drywall has the following dimensions.

Different manufacturers may deviate from standard sizes and produce products with slightly different dimensions. Sometimes even the weight of the same profile (the same size) will differ for different manufacturers.

Metal guides for hl - possible sizes

Choosing guides in a hardware store, you need to pay attention to their thickness. If they are too thin, it is better to choose another product, even if it is more expensive. If the manufacture used thin steel, the screw in the process can be scrolled in one place.

Trying to save on repairs, many want to take materials on the market. In search of where it is cheaper, you can stumble upon a low-quality product. The presence of traces of corrosion should instantly repel the desire to buy guides. Sellers sometimes deliberately lubricate the defective batch to hide defects. If the profiles shine, then the matter is not clear.

High-quality metal profile - a guarantee of reliability of the frame

In order for the installation of drywall guides to be of high quality, it is necessary to use products with proper rolling. Such defects are clearly visible, because the profile will not be smooth, but slightly twisted. Distortion of the parts in any direction will create a lot of problems during the repair. Therefore, we choose only perfectly flat products.

Few people want to be mistaken with the choice of quantity and then run back to the store or think about where to place the leftovers. It is necessary to calculate the guides for drywall to buy just as much as you need.

For self-calculation, you just need to draw a sketch of the future structure. It remains only to calculate their total length and buy the right amount of material. In this case, it is necessary to take into account the possible marriage, as well as working waste. For example, a 3-meter rail is mounted on a wall with a height of 2.7 meters. As a result, cut 30 centimeters can be thrown out.

For the most curious there is a video about how guides are created.

Consider how to properly install the guides under the drywall. First you need to purchase the profile itself. Much has been written about its varieties and selection rules, but it is not clear what size to prefer. Here everything is individual and depends on specific needs.

For small structures, a small section profile is selected. If bulky structures are created, on which a high load-bearing load is carried out, then larger guides should be taken. The main thing is to take a profile of the same size, if only it will be in operation. Usually use UW 50 (50x40 mm).

The size of the profiles for the gypsum board is selected depending on the expected load

The design will always be attached to the wall, and sometimes to the walls. It may also require mounting to the floor and ceiling. All these points are thought out in advance, and you may need to create a special sketch. With the layout on paper, it is easier to assemble the frame. Fastening drywall guides to walls should be done after marking.

Preliminary marking is needed to indicate the main mounting points of the guides. For its implementation will require:

Marked lines should mark the edge of the profile. It is necessary to apply the guide so that the line is visible, then everything will be smooth.

After marking, it's time to figure out how to fix the drywall guides to the wall. Since rack profiles will not be used, there is no need for direct suspensions to fix them.

The guide profile is always used as the basis for the frame. It must be fixed to the wall with dowels. Some guides already have holes for mounting, which will simplify the work of beginners. If there are no holes, then they will have to be done. Also drilled surface to which the profile should be attached. A step of 40 cm will be sufficient.

A guide with prepared holes is applied to the hole in the wall along the marked lines. Through it, the dowel is thrust into the wall and the screw is screwed in (screwed in). Screws need to score until the very end, so that they do not stick out. Similarly, all profiles are created that create the outer part of the frame.

Profiles of the same size tightly connected to each other.

To enhance the design guides are installed in the middle of the frame. The distance between the guides for drywall should be 40 cm. If you take a larger step, the design can come out unreliable.

Profiles of the same size are tightly inserted into each other. The guides running along the perimeter are installed with their backs to the wall (or floor, or ceiling), and outwardly protrude from one of the ribs. Drywall will be attached to this edge. In these profiles, new guides are installed so as to also look one edge out, and your back to the side. As a result, the drywall will be attached to the edges of the profiles, and not to their backs, as if installing a rack profile.

With this method of installation, there should be no questions about how to put the guides under the drywall level. It does not use suspensions, and guides along the perimeter of the structure were exposed using a level.

It is not recommended to fasten profiles to each other with self-tapping screws because of the caps that will protrude and will not allow to put the drywall on the structure exactly.

To connect the guides for drywall between them, you must use a special tool prosekatel. With its help, all metal parts of the frame are attached that are in contact with each other. The result will be a strong frame that will hold, including thanks to the gypsocratone, which will attach to it in all places.

Что бы оставить комментарий войдите

Комментарии (0)