Labor protection is a complex of legislative, technical, sanitary and hygienic and organizational measures aimed at ensuring healthy and safe working conditions. This complex includes three sections: labor legislation, safety engineering and industrial sanitation. The fundamentals of labor legislation are set out in the Labor Code (Labor Code). Safety includes a set of technical and organizational measures, the implementation of which is intended to ensure safe working conditions primarily by preventing and eliminating the causes of accidents (injury prevention). Industrial sanitation is a medical field dedicated to the study and prevention of occupational diseases.

Control over the state of labor protection and safe methods of work is assigned to the engineering and technical personnel of construction. Public control is carried out by labor protection commissions of factory, building and shop trade union committees.

Technical personnel have the responsibility to provide general safety training for the workers each year. Newly accepted workers are allowed to work only after they undergo an introductory briefing on safety. In addition, no later than three months from the date of receipt of the workers for construction, they are trained under an approved program to comply with the rules of safety, occupational health, industrial sanitation and fire prevention measures; test knowledge and issue certificates. When a worker is transferred to a new job, when the conditions and nature of work change, or when a task for particularly dangerous work is issued, additional safety instructions are given to show safe work practices.

The introductory and production briefings are recorded in the journal, where the instructed workers and the engineering and technical workers who instruct are signatures.

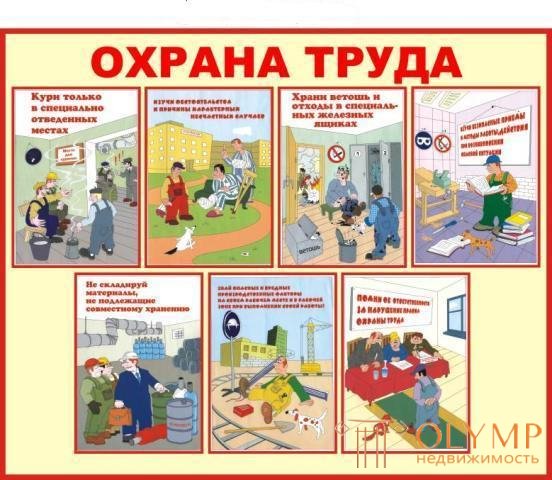

Safety Instructions To create a safe working environment construction sites are fenced off. At the construction site posted signs of aisles and passages. Driveways should always be free from materials, debris, snow, ice. Hazardous areas protect and illuminate at night. In addition, posters warning people about danger are posted near such places.

Switching on and off of electric lighting, machines, machines, lifting mechanisms is carried out only by specially selected persons. Switches and circuit breakers must be in locked and locked drawers.

To work electrified and pneumatic tools allowed persons who have received special training.

The enclosures of power tools operating at voltages above 36 V must be grounded.

Connecting hoses to compressed air pipelines is allowed only through valves installed on air distribution boxes or outlets from the main line.

During off-hours, during maintenance and repair, all machines and mechanisms must be in a position that excludes the possibility of their launch by unauthorized persons.

When plastering window and door slopes and blind spots, the openings are shielded.

Garbage, boards from a building under construction are lowered down closed gutters and not dumped.

All construction work, including plastering, should be carried out according to the plan and schedule, linked to the timing and time with other works.

Prior to plastering, check the strength of the installation of all partitions. If you have to carry out plastering work to the device floors, be sure to lay on the beams of floors continuous temporary flooring of the boards. Without a permanent floor or temporary flooring can not work.

Quicklime clod lime, or fluff, is stored in closed warehouses or chests with a dense floor, arranged above ground level for not less than 0.2 m. Lime pits are fenced and covered with boards or shields.

Before starting work, plasters must familiarize themselves with their workplaces, remove all unnecessary objects and especially boards with protruding nails. If the boards can not be removed, it is necessary to bend the nails.

Before starting work it is recommended to inspect the instrument and fix all defects. Inspect and check with the construction master the condition of the scaffolding, scaffolding and cradles and systematically monitor them throughout the entire period of work.

When working at height use safety belts. Safety belts must have a passport; every 6 months they are tested for a static load of 3000 N for 5 min. A number and a tag with the date of the test are attached to the belts.

Maintenance of machines or mechanisms is allowed only by specially trained plasterers who have certificates. It is forbidden, without a driver, to set in motion mechanisms or machines, to remove or put on driving belts on the move.

Everyone should remember that, violating safety regulations, he endangers not only himself, but also a number of working comrades.

Industrial sanitation . A major role in increasing labor productivity and reducing injuries is played by industrial hygiene and occupational health.

The incorrect position of the body of the worker when he performs work not only increases fatigue, but also reduces attention to work. This leads to a decrease in labor productivity, blunting of attention, which increases accidents. For example, when plastering ceilings a large role is played by the ratio of the height of the scaffolding and the height of workers. For normal operation, it is necessary to make scaffolding of such a height that the ceiling above the head is no higher than 20 cm. If the height is greater, the workers get tired faster and their productivity decreases.

A major role in creating normal working conditions is played by overalls. Coarse and narrow clothes hamper movement, and this quickly tires and reduces worker productivity. Workwear material should be tight, but soft. Dense material does not allow dust, protecting the body from rapid contamination, soft material is easily bent, which creates convenience when working. Plasterer use a variety of workwear: overalls, robes and jackets with trousers.

Handles of tools should have a smooth surface. Recommended handles falcons, graters, poluterkov, hammers cover with linseed. Pro-lyophilized products sticks less solution, they do not get wet, they are easier to keep clean. Keeping the instrument clean and properly cared for reduces injuries.

When slaked lime boils, highlighting a large number of splashes that can cause burns. When loading lime, it is dusty, causing irritation of the mucous membranes of the eyes, nose, throat, so the worker must protect the face with a respirator or gas mask, work in overalls, gloves, rubber boots.

Plasterer, you have to work with alkaline materials destroying the skin (lime and cement), and also apply hydrochloric acid to clean contaminated surfaces. During operation, especially during repairs, there is a lot of dust. Contamination of the skin of the hands or body leads to various diseases. To protect your hands from damage and dirt, use mittens, protective ointments or pastes.

An important preventive measure is the timely treatment of small wounds with a disinfectant solution. For this purpose, a supply of disinfecting materials is stored in construction kits: hydrogen peroxide, iodine tincture, hygroscopic cotton, sterile bandage.

Fire fighting activities . When performing plastering work using heating appliances. Heating the room, heating the solutions, materials, water, it is necessary to strictly observe the rules of fire safety.

When using temporary heaters, they should not be left unattended. After completion of work, the devices should be turned off There must be a sandbox, a water tank or a fire extinguisher, which must be able to use plasterers, near each temporarily supplied stove or heater.

All electrical wiring must be performed in accordance with the rules of safety and fire safety. It is strictly forbidden to use electrical wiring with faulty insulation. After completion of work, lighting devices must be turned off.

Smoke should be in designated areas where the dishes are placed with water or sand. It is forbidden to smoke or use open fire at a distance of less than 10 m from cylinders with acetylene and other flammable gases, as well as from gas pipelines, mobile acetylene devices and sludge pits (pits where spent carbide is dumped).

In the hot season, the wooden elements of the forest should be periodically watered.

In the warehouses with lime foam fire extinguishers are hung; water cannot be used to extinguish lime.

Что бы оставить комментарий войдите

Комментарии (0)