The reinforcement of reinforced concrete structures consists of working rods, which are calculated according to the acting forces, and assembly, which serve to unite the working rods into reinforcing meshes or frames.

Stamps and grades of reinforcing steel.

Reinforcement products

Brands of hot-rolled reinforcing steels denote their chemical composition. The double digits on the left characterize the average carbon content (in hundredths of%), and the letter and numbers after them - the content of alloying additives - chromium (x), manganese (g), silicon (s), titanium (t). For example, steel grade 25G2S contains 0.25% carbon, 2% manganese, 1% silicon.

Rod reinforcement is divided into classes: hot-rolled AI, AII, AIII, A IV; thermally hardened At IV, At V

Steel class AI-round (smooth) with a diameter of 6-40mm. It has low adhesion to concrete and has low strength, therefore it does not apply to working reinforcement.

Steel class A-II with a diameter of 10 ... 40 mm is made of carbon steel; diameter 40-90mm of low-alloy steel 18G2S. Rods of a periodic profile are formed by frequently located protrusions running along a 3-way helix with 2 longitudinal ribs.

Steel class A-III (grades 25 G2S and 35GS)

Periodic a profile with protrusions forming a “herringbone” rolls with a diameter of 6 to 40 mm.

To increase the yield strength, hot-rolled reinforcing steels of classes A-II and A-III in some cases are subjected to hardening by drawing. Hardened steel belongs to classes A-IIb and A-IIIb.

Thermally hardened reinforcing steel of At-IV class At-VII is manufactured with a diameter of 10-25 mm. In addition to hot-rolled steel, ordinary reinforcing wires of classes BI and Bp-I (fluted) ¯ 3-5 mm, obtained by cold drawing low carbon steel, are widely used for reinforcement of reinforced concrete structures.

In the same way, high-quality reinforcing wire of class B-II and Bp-II is made of a smooth and periodic profile with a diameter of 3-8 mm.

For the main working reinforcement of reinforced concrete structures, hot rolled steel of classes A-II and A-III and reinforcement wire of class Bp-I should be used.

In prestressed structures, reinforcement wires are used primarily for high-strength reinforcing wire of classes B-II and Bp-II, hot-rolled rod steel of class At-IV At-V.

The reinforcement of prestressing structures with high-strength wire is very effective, however, due to the small cross-sectional area of the wires, their number in structures is very large, which complicates the reinforcement works.

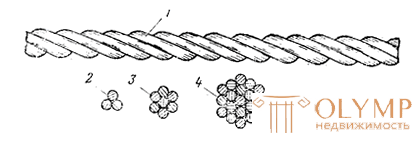

To reduce the labor intensity of the reinforcement works, pre-twisted strands and bunches are widely used.

Non-spinning class P steel strands are made from 3X wires

(P-3), from 7 wires (P-7) and 19 wires (P-19) “K” class steel ropes are made from 2X

and more strands.

To designate a reinforcing rope, two numbers are added to the letter K: the first indicates the number of strands being twisted, the second the number of wires in each strand (K2 X 7) is a two-strand seven-wire strand, and for short “K-7”.

Depending on the nature of the work, the following types of fittings are distinguished:

1) Working, perceiving tensile, and sometimes compressive forces in the elements of reinforced concrete structures.

2) Distribution, ensuring the joint work of the bars of the working reinforcement, perceiving local efforts that are not taken into account by calculation

3) Mounting, ensuring the design position of the working reinforcement and necessary for assembling the rods into reinforcing meshes and frameworks. Often the same valve performs the role of working, distribution and installation.

The cross-sectional area of the working reinforcement before the calculation, and the assembly and distribution section - structurally in accordance with the instructions of the SNiP.

Depending on the nature of the reinforcement and the type of cross section, the working reinforcement is divided into flexible and rigid.

Flexible - is pivotal and wire.

In some cases, for the construction of monolithic reinforced concrete buildings for buildings and structures, rigid reinforcement is used.

Such reinforcement should be perceived in the course of the production of the weight of the formwork suspended to it, concrete, fixtures, etc.

Supporting fittings eliminate the need for scaffolding.

Rigid reinforcement is made of rolled profiles: I-beams, channels, corners. Together with the rolled products, flexible fittings are sometimes used additionally.

Что бы оставить комментарий войдите

Комментарии (0)