The quality of surface finish with cladding sheets depends largely on how the seams and seams are trimmed. Joints are best closed with the same mastic on which the sheets are pasted. You can use a gypsum binder, shut up at 3% glue water, or semi-oil putty. Before using the putty, it is recommended to pre-seam the seams, which provides a stronger adhesion of the mastic to the seams of the sheets.

The seams are open and sealed flush with the surface of the sheets. The seams are embroidered 3-5 days after the lining, when the mastic has dried and there is no moisture in the space between the structure and the sheets.

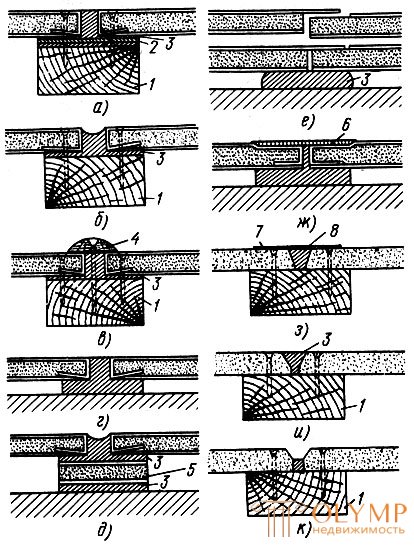

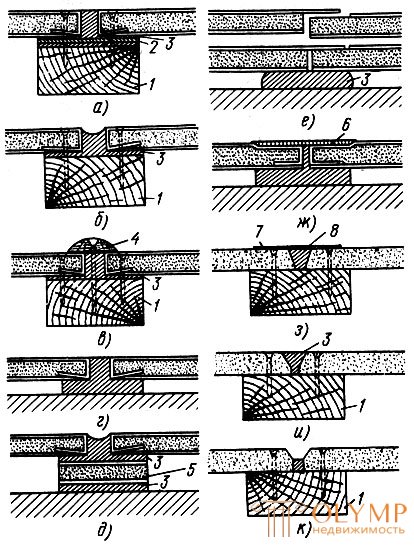

If the cladding sheets are attached to a wooden frame, the seams are cut in the following ways.

The first method (Fig. 134, a). Bar 1, on which the sheets are joined, is smeared with mastic. Cardboard strips 2 are glued onto mastic 3. The mastic is again smeared on the cardboard strip and the sheets are pressed against it, leaving a gap between them. putty and stripping.The cardboard is glued to prevent the formation of cracks along the seam line.This kind of cutting seams is used both for painting and for pasting wallpaper.

The second method (Fig. 134, b). On the bar 1 smear a layer of mastic and pressed sheets to it. Mastic in the seam align flush with the sheets or embroidered groove. This method is less labor-intensive than the previous one, but in this case a crack may form along the seam line. Such a seam is closed with a wooden bead, which is strengthened with nails or screws (Fig. 134, c). This option of cutting seams is used only for surfaces to be painted.

When the sheets are attached to the mastic to the stone structures (Fig. 134, d), along the joint line the mastic is applied in a continuous strip. The mastic extruded from the seam is compared flush or embroider. Often under the seams enclose the strips, cut from cladding sheets. The strips are pasted on the surface with mastic and then sheets are pressed onto them (Fig. 134, e).

To make the seams invisible, a strip of cardboard 20-30–30 mm wide is removed from the edge of one sheet, and a strip of a gypsum core is cut from the other, but so that a strip of cardboard remains. After fixing the sheets with mastic or nails, the remaining strip of cardboard is smeared with wood glue and sealed with a seam (Fig. 134, e). This method is used mainly for cutting seams on ceilings to be painted.

Sheets with crimped edges (Fig. 134, g, h) are reinforced with mastic. Mastic, extruded from the seam, compare. After it dries, the seam is spat. On putty often stick a strip of paper or gauze. Then one more time they putty flush with the sheets and after drying they grind. When the seam remains open, it is filled with filler completely or only half (fig. 134, and, k). The seams can also be closed with bead 4.

To obtain smooth and smooth seams, it is recommended to cut them with a jointing or a template. The jointing and pattern needs to be moved according to the rule. The applied mastic or mortar is completely removed from the front side using a cut-off or steel spatula. All roughness smooth out sandpaper.

Fig. 134. Processing of joints (seams) between sheets: fastening of sheets: a, b, c, s, and, k - to a wooden frame, g, d, e, w - to stone structures; 1 - bar, 2 - cardboard, 3 - mastic, 4 - bead, 5 - dry plaster, 6 - putty with a strip of paper or gauze, 7 - gauze, 8 - putty

Что бы оставить комментарий войдите

Комментарии (0)