A stucco coating usually consists of three layers - a spray, a primer and a covering. This is due to the fact that applying a plaster solution to the entire thickness of the layer at once is not allowed, since the plastic solution will drain from the surface without grasping it.

Spray - the first (lower) applied directly to the surface to be plastered, a layer of the most plastic solution with a draft of a standard cone of 8 ... 14 cm for mechanized application and 11 ... 12 cm for manual application (water content up to 60% by volume knitting). The thickness of the layer of spray on the stone and concrete walls take 4 ... 5 mm, on wooden surfaces - 7 ... 9 mm. Before applying the spray stone and concrete surfaces moistened with water. Spraying is usually not smoothed and leaves the surface rough, its main purpose is to firmly grasp with the plastered plane by filling all its irregularities, pores, voids and be able to perceive and bear the load from the subsequent layers of plaster. If you compare the purpose of spray with other finishing processes, it plays the role of soil for subsequent finishing layers.

sprayed . It is a layer of 5 mm (for stone and the like walls) or 9 mm (for wooden walls, including drani), thrown over in a continuous layer on the basis of a layer of liquid solution (like liquid sour cream). The surface is not leveled, the main task is to obtain a rough layer on a smooth wall or fixing to shingles, if we are talking about plastering a wooden base. After setting, they proceed to subsequent work;

Soil - the second layer of bent, designed to align the plaster surface, creating the basic thickness of the plaster bent; the primer is usually applied in several layers after the start of hardening of the solution in the spray layer. The solution is used with a draft of a cone 7 ... 8 cm (water content 30 ... 40% of the volume of the binder), each subsequent layer of soil is applied after setting and whitening the previous one; layer thickness should not exceed 5 mm with cement mortars and 7 mm - with lime.

ground It is the main leveling plaster layer. For its formation using a solution in the consistency a la dough, can be in several layers, if necessary, to correct the wall geometry. The thickness of each layer is determined by the limitations of the producers of plaster. As a rule, it is 20-30 mm, but according to the standards it should not exceed 5 mm for cement plasters and 7 mm for all others. Layers are applied after the base has set, each of them is leveled;

Cover - the third, finishing layer of plaster, applied in one step at a thickness of not more than 2 mm; the purpose of the layer is to prepare the surface to be painted for painting, to give the plaster an even and smooth surface. A solution for this layer is prepared on fine sand with a draft of a cone of 9 ... 12 cm and a water content within 50% of the binder volume. Patch applied after hardening of the soil to a state where light pressure leaves a dent on it.

nakryvka . Finishing leveling layer of plaster, which is used for leveling minor defects of the coating. It is applied on the set or hardened wetted soil with a thickness of 2 mm. The consistency of the solution is the same as when sprayed. The coating is carefully smoothed to get the perfect result.

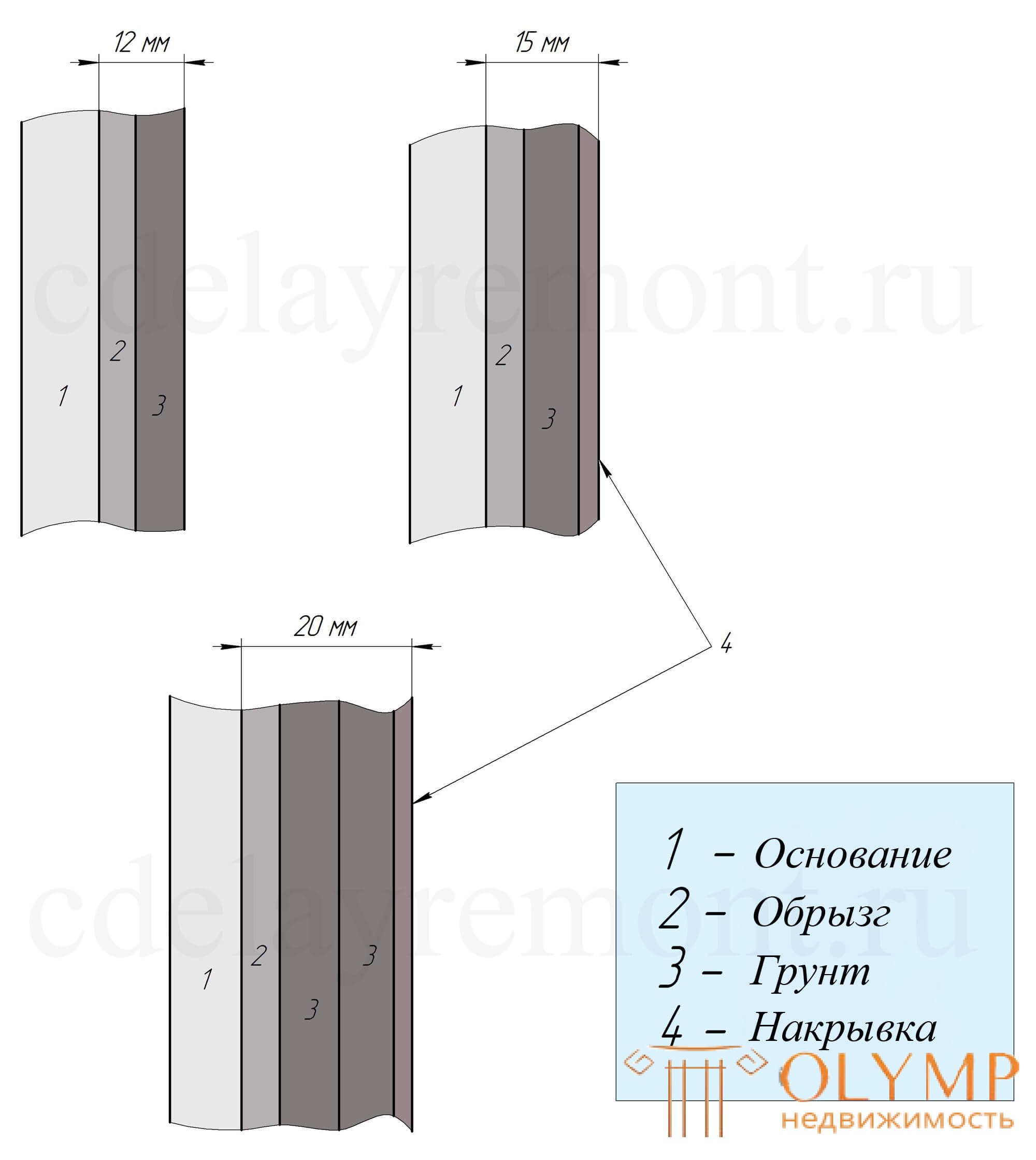

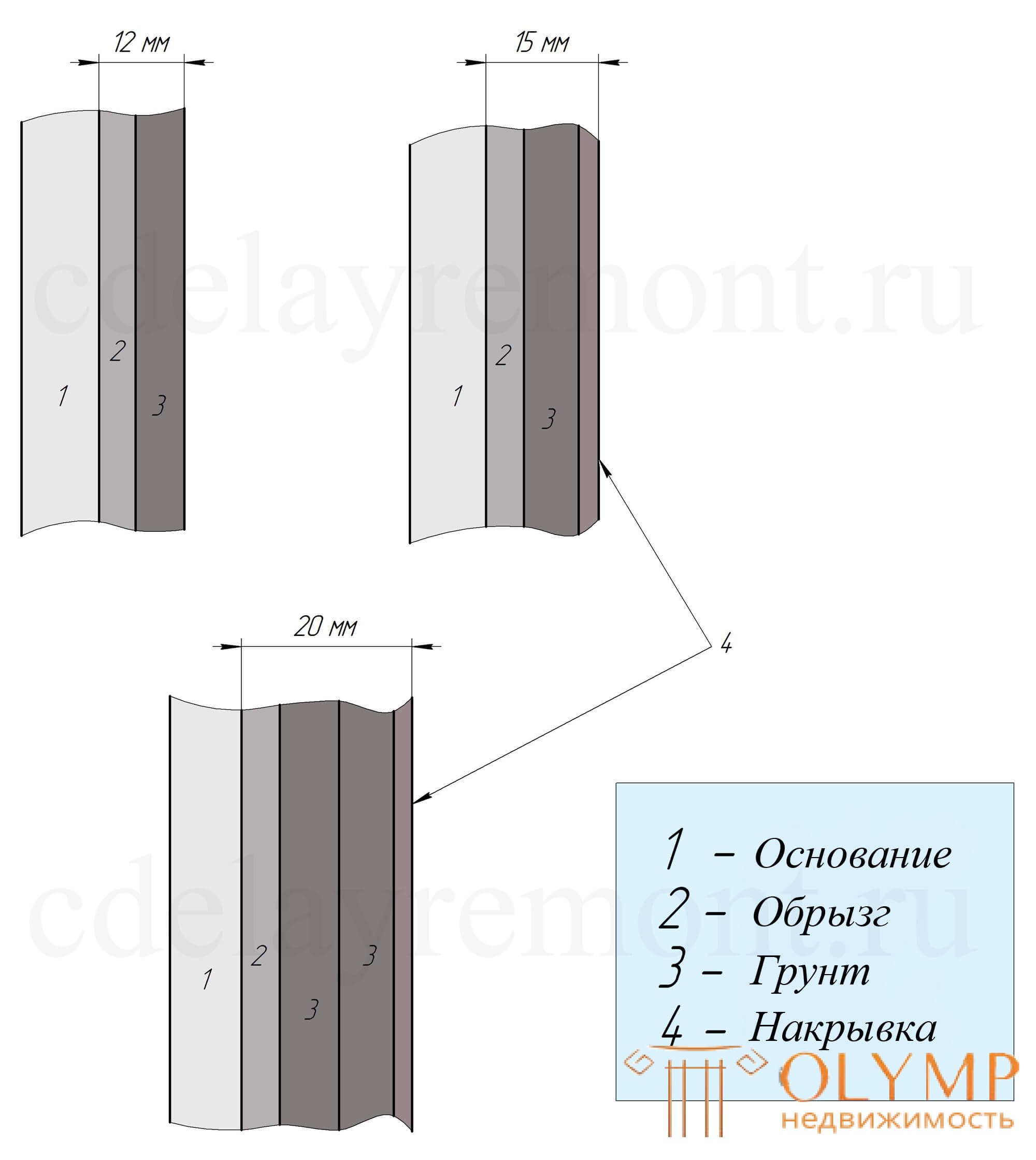

The total thickness of the plaster should be in the range of: simple —— 12 mm, improved — 15 mm, and high quality — 20 mm.

The difference between the approaches in preparing the base for subsequent finishing works can be represented as follows (see the table below).

| Types of plaster: | ||||

|---|---|---|---|---|

| High quality | ||||

| Improved | ||||

| Simple | ||||

| Splattered | Soil, leveling coating and grouting | Cutting of corners, ceiling rustov, whiskers, husks | Cover grout | The same, but more than one layer of soil |

The number of layers is determined by the degree of curvature of the plane and the technical characteristics of the solutions used. For example, for gypsum and cement mixtures, the requirements differ significantly. There should be considered a specific composition, so when plastering your own hands, you should be familiar with the manufacturer's recommendations, indicated on the packaging or in the accompanying documentation.

Что бы оставить комментарий войдите

Комментарии (0)