To obtain high-quality plaster, having a certain texture and properties (sound insulation, heat insulation, moisture resistance), various materials are used: binders, fillers, water, additives.

Binding - powdery substances, after mixing with water, they pass over time from pasty to stone-like state. Binding, hardening and gaining strength only in air, called air-curing binder. Binding, preserving and increasing its strength in air, but even better in water or in wet conditions, is called hydraulic curing binder.

The main binders used for plastering work are: cements (portland cement, pozzolanic, slag portland cement, expanding, hydrophobic, acid-resistant, colored and other special cements), gypsum, building lime (quick-milled, lime paste and hydrated lime), clay.

Aggregates - an integral part of solutions, which include sand, slag, crushed stone, other materials.

Apply sand mountain, river, sea, lake and career with grain sizes from 0.3 to 5 mm. The content of clay particles in the sand more than 5% is unacceptable. The density of the sand is 1.5 ... 1.7 t / m3. For plastering works, the sand is an acute-angled form of medium and small (but not dusty) size. It is allowed to use natural gravel, not crushed, rounded form and natural crushed stone, crushed, torn acute-angled form, with grains of 2.5 ... 20 mm in size. The considered aggregates are heavy with a density of more than 1000 kg / m3.

Lightweight aggregates for plaster mortars have a density of less than 1000 kg / m3. Slag - pieces of torn form, the product of burning coal. To obtain slag sand, slag is ground in mills and sieved. Such sands with a density of 0.7 ... 0.9 t / m3 are used as sound- and heat-insulating material when plastering partitions and external facades. Pumice is a porous volcanic rock with a density of up to 0.6 t / m3. Charcoal is added to the plaster solution to reduce the mass of plaster.

Decorative aggregates are used in plasters to give them shine and a more expressive appearance. They are applicable when the plaster is the final layer of surface finish. These fillers include mica, anthracite, quartz, broken glass, stone chips. Mica and broken glass with a particle size of 1 ... 6 mm are added in a small amount to the solutions in order to impart crystalline gloss to the surfaces.

Stone chips of various colors are obtained by crushing marble, granite, limestone and other stone rocks. Stone mortar with grains of size 0.3 ... 5 mm is added to mortars. When smoothing and polishing the set solution, the surface acquires brilliance and the seeming texture of natural material.

Supplements can be divided into three main groups. Mineral and organic additives - ashes, slags, pumice, tripoli, diatomites, pozzolana, burnt clay. When mixed in a finely divided state with air lime and when mixed with water, they form a dough that is capable of hardening and under water after hardening in air.

Chemical additives impart water resistance and other protective properties to cement mortars. Such additives include soluble (liquid) glass. This is a heavy thick brownish yellow liquid, which is dissolved in water in a ratio of 1: 6. This solution shut the prepared dry mixture. When hardening, liquid glass forms a waterproof and fire-resistant film on the surface of the plaster. This plaster mortar is used for plastering wet places.

Plasticizing additives are technical lignosulfonates (LST), mylonaph, wood pitch and a whole range of other additives listed in GOST 24211-2003 “Additives for concrete and mortars”. They increase the plasticity of solutions, workability, frost resistance, reduce the consumption of cement. In cement mortars, clay and lime are also used as plasticizers. Apply cold-resistant additives for outdoor use.

Plaster solutions are used for interior and exterior of buildings. When hardening, the solutions turn into a solid stone-like mass.

The quality of the solution involves the provision of several important characteristics. Freshly prepared solution should be workable, have good mobility, plasticity, water-holding capacity, good adhesion (adhesion) to the base; the solution on the surface should quickly harden, have the desired thickness, do not give much shrinkage and not crack when dry.

Workability - the ability of the solution is easy; applied and distributed on the surface, well filling with all the irregularities. Such properties are inherent in fatty plastic solutions - clay, lime and mixed, and they are practically absent in hard cement mortars.

Mobility - the ability of the solution when applied to the surface to spread over it without the application of special force effects.

Plasticity is the property of the solution to take and maintain the shape given to it with the help of a working tool.

Plasticity is the property of the solution to take and maintain the shape given to it with the help of a working tool.

Water retention capacity - the ability of a solution applied on a porous base to slowly give it its moisture.

To obtain solutions of good quality, it is necessary to correctly calculate its composition. Liquid solutions are used for applying an explosion, semi-liquid - for nakryvki, semi-thick - for soil. For thick plastering scale, performed on the grid, apply thick mortar mixes. With an increase in the binder solution, its plasticity and workability increase, and with the addition of water, a transition from thick solutions to liquid occurs.

Solutions are used simple (clay, lime and cement) and mixed.

Clay mortar is used for dry interior. The lack of solution - low strength, easily eroded by water. It is advisable to arrange the top of the lime or lime-gypsum mortar. In recent years, simple clay solutions are practically not used.

The composition of the clay solution for oily clay - for 1 part of clay is 4 ... 5 mass. h. sand; for average clay - 3 ... 4 hours of sand, respectively; for lean clay, the ratio decreases - for 1 part of clay there are 2 ... 3 hours of sand. For greasy clay, it is desirable to use mixed solutions, for example, for 1 hour, for clay, 0.3 parts of lime and 5 parts of sand are taken; when using cement - for 1 part of clay: 0.15 part of cement: 4 parts of sand.

Lime mortar is used for plastering internal and external surfaces on brick, concrete and wood. The most durable is the plaster in dry rooms. Basic compositions (lime paste and sand) - from 1: 1 to 1: 4. Solutions with an excess of lime crack, and with an excess of sand does not crack, but have a reduced strength. Simple lime solutions are manufactured with strength characteristics for grades from 4 to 10.

Cement mortar consists of cement, sand and water. It is used for surfaces exposed to moisture. The possible proportion of the compositions is from 1: 1 to 1: 6, the most flexible and often used solution composition is 1: 3. Portland cement is mainly used for the preparation of plaster, pozzolan cement is used for waterproof plaster, less often polymer-based cements.

Complex solutions - lime-gypsum, cement-lime. Lime-gypsum mortar is applicable for interior work, for 1 part of gypsum take 3 parts of lime.

Cement-lime mortar , in which for greater plasticity using lime paste. In the composition of the solution components can be changed significantly from 1: 1: 6 to 1: 3: 15.

Solutions on quicklime ground lime , in which there are 0.5 parts of cement and 4 parts of sand for 1 part of lime, are pre-treated for 30 ... 40 minutes before being applied to the surface.

The type of plaster used depends on the purpose of the room and the material of the surface being trimmed. Concrete surfaces are plastered with complex solutions of cement, lime and sand of an approximate composition of 1: 1: 8, the mobility of the solution with a draft of a standard cone is 7 ... 9 cm. Brick surfaces are plastered with lime-sand solutions of a composition of 1: 3 and mobility 9 ... 12 see. When plastering wooden and gypsum-concrete surfaces, lime-gypsum sand solutions are used, for sanding surfaces of rooms with high humidity (basements, baths, sanitary facilities), cement-sand solutions of elevated brands with hydraulic surfaces are used. Special additives.

All types of solutions, their compositions and properties, purpose and features of the application are given in GOST 28013-98 Building solutions. General specifications and GOST 5802-86 (from 1989) Building mortars. Test methods

Dry mixtures are widely used, which are packaged in moisture-proof packaging, which contains information about the mixture, its name and brand, strength characteristics of the finished product, recipe and instructions for preparation, date of manufacture and shelf life before sale.

Plaster dry mixtures are made on the basis of cement, lime, gypsum or mixtures thereof. The aggregate size can vary from 0.5 to 1.2 mm. The strength mark of the M25 ... M450 solution. Mixtures are designed for plastering and finishing the outer and inner surfaces of the walls. Universal mixes are prepared, which are used for concrete, brick, foam concrete and other surfaces. There are many variations of mixtures for specific applications.

Decorative dry mortar mixtures used for final finishing of various surfaces. Dry mixes are used when monolithing the joints of structures to obtain high strength in a short time. Leveling mixtures have been used when it is necessary to obtain a smooth vertical surface for painting or gluing wallpaper, and the mixtures can be universal, or only suitable for dry and damp rooms.

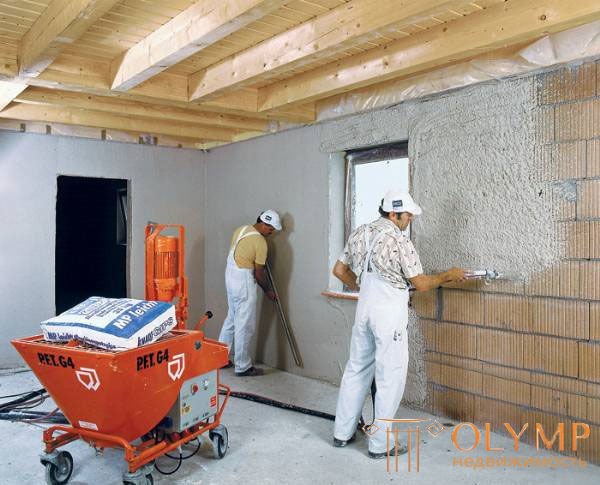

Self-leveling mixes for the floor allow you to level and strengthen the base. They can be used for floor screeding, for laying the floor of ceramic and concrete tiles, carpeting, parquet. There are options for dry mixes for the device wear-resistant coatings. With mixtures on synthetic resins and when applying the solution using a mortar pump, significant areas can be obtained.

di seamless self-leveling coatings. This technology is widely used when plastering walls.

di seamless self-leveling coatings. This technology is widely used when plastering walls.

Heat-insulating dry mixtures are used to improve the heat and sound insulation. Perlite, expanded clay sand, other types of light aggregates are used as aggregate. Such mixtures are suitable for exterior and interior use, the density of such mixtures is 400 ... 650 kg / m3.

Waterproofing mixtures for insulation of underground parts of buildings, basements and basements are prepared on special and expanding cements, which include hydrophobic additives and micro-fillers.

Dry mixes for repair and restoration of surfaces are high- adhesive cement-sand based solutions or modified mixtures. For the repair of wet surfaces and in the presence of efflorescence, special formulations are used. Depending on the condition of the surface to be strengthened, it is possible to use successively three solutions and layers: waterproofing, coating and finishing on finely dispersed chalky, gypsum mixtures or using white or colored cement.

Что бы оставить комментарий войдите

Комментарии (0)