There is a legend about a "breathing wall", and epic legends about "healthy breathing cinder block, which creates a unique atmosphere in the house." In fact, all these are fairy tales. The vapor permeability of the wall is not large, the amount of steam passing through it is not significant, and much less than the amount of steam carried by air when it is exchanged indoors.

Vapor permeability - one of the most important parameters used in the calculation of insulation. We can say that the vapor permeability of materials determines the entire structure of insulation.

Movement of steam through the wall occurs when the difference in partial pressure on the sides of the wall (different humidity). In this case, the difference in atmospheric pressure may not be.

Vapor permeability - the ability of the mother to pass steam through itself. According to the national classification, it is determined by the vapor permeability coefficient m, mg / (m * h * Pa).

The resistance of the material layer will depend on its thickness.

It is determined by dividing the thickness by the vapor permeability coefficient. Measured in (m sq. * Hour * Pa) / mg.

For example, the vapor-permeability coefficient of a brickwork is taken as 0.11 mg / (m * hour * Pa). With a brick wall thickness of 0.36 m, its resistance to vapor permeability will be 0.36 / 0.11 = 3.3 (m sq. * Hour * Pa) / mg.

Below are the values of the vapor permeability coefficient for several building materials (according to the regulatory document), which are the most widely used, mg / (m * h * Pa).

Bitumen 0.008

Heavy concrete 0.03

Autoclave aerated concrete 0.12

Expanded clay 0,075 - 0,09

Slag concrete 0.075 - 0.14

Burnt clay (brick) 0.11 - 0.15 (in the form of masonry on cement mortar)

Lime solution 0.12

Drywall, Plaster 0.075

Sand cement plaster 0.09

Limestone (depending on density) 0.06 - 0.11

Metals 0

Chipboard 0.12 0.24

Linoleum 0,002

Foam 0.05-0.23

Polyurethane solid, polyurethane foam

0.05

Mineral wool 0.3-0.6

Foamglass 0.02-0.03

Vermiculite 0.23 - 0.3

Expanded clay 0.21-0.26

Wood across the fibers 0.06

Wood along the fibers 0.32

Brickwork from silicate brick on cement mortar 0.11

Data on vapor permeation of layers must be taken into account when designing any insulation.

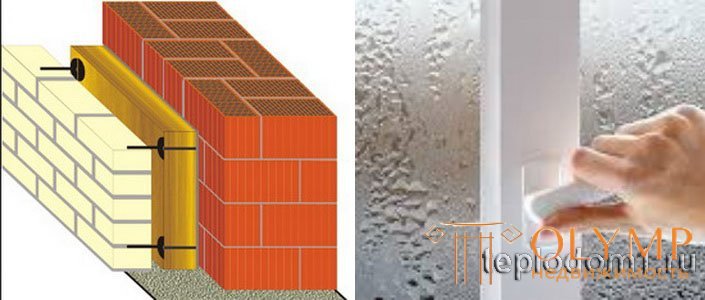

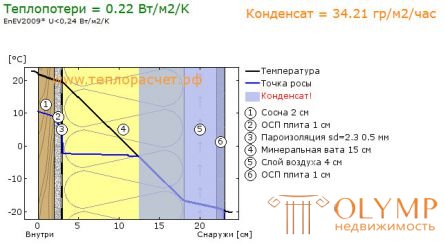

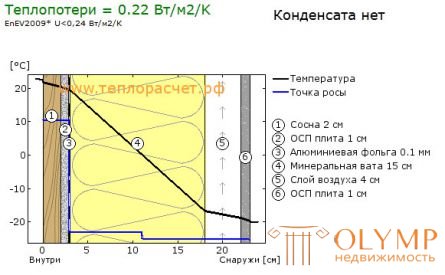

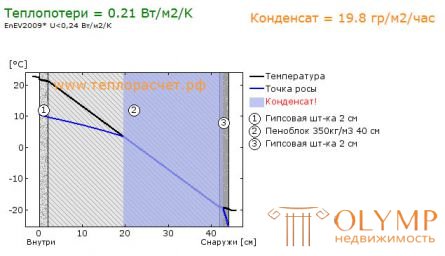

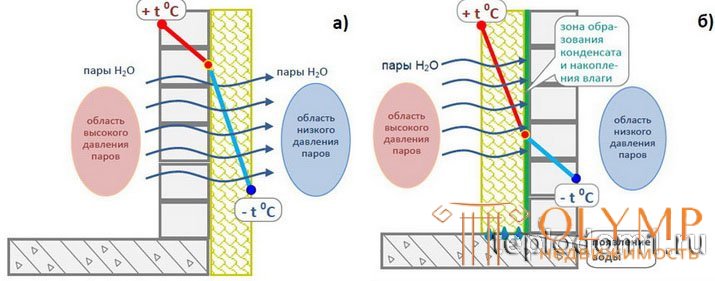

The basic rule of warming - the vapor transparency of the layers should increase in the outward direction. Then, in the cold season, it is more likely that water will not accumulate in the layers when condensation occurs at the dew point.

The basic principle helps to decide in any cases. Even when everything is “turned upside down” - it is insulated from the inside, despite persistent recommendations to make insulation only from the outside.

Whatever the catastrophe happens when the walls get wet, it’s enough to remember that the inner layer must resist the pair most stubbornly, and based on this, use extruded polystyrene foam with a thick layer - a material with very low vapor permeability - for internal insulation.

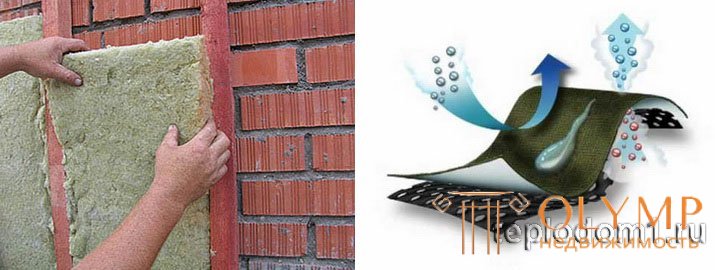

Or do not forget to use even more “airy” mineral wool for very “breathing” aerated concrete outside.

Another way of applying the principle of vapor transparency of materials in a multilayer structure is the separation of the most significant layers by a steam insulator. Or the application of a significant layer, which is an absolute vapor barrier.

For example, the insulation of a brick wall with foam glass. It would seem that this is contrary to the above principle, because the accumulation of moisture in a brick is possible?

But this does not happen, due to the fact that the directed movement of steam is completely interrupted (at subzero temperatures from the room to the outside). After all, foam glass is a full vapor barrier or close to it.

Therefore, in this case, the brick will enter the equilibrium state with the internal atmosphere of the house, and will serve as the accumulator of moisture during its sharp jumps inside the room, making the internal climate more pleasant.

The principle of separation of layers is used and applying mineral wool - insulation is particularly dangerous for moisture accumulation. For example, in a three-layer construction, when mineral wool is inside the wall without ventilation, it is recommended to put a vapor barrier under the cotton wool, and leave it, therefore, in the outer atmosphere.

The international classification of materials according to vapor barrier properties differs from the domestic one.

According to the international standard ISO / FDIS 10456: 2007 (E) materials are characterized by a coefficient of resistance to movement of steam. This coefficient indicates how many times more material resists the movement of steam compared to air. Those. in air, the coefficient of resistance to steam movement is 1, and in extruded polystyrene foam it is already 150, i.e. expanded polystyrene is 150 times less vapor than air.

Also in international standards, it is customary to determine the vapor permeability for dry and wet materials. The boundary between the concepts of "dry" and "wetted" selected internal moisture content of the material in 70%.

Below are the values of the coefficient of resistance to the movement of steam for various materials according to international standards. First, data for dry material are given, and comma-separated for wet (more than 70% moisture).

Air 1, 1

Bitumen 50,000, 50,000

Plastics, rubber, silicone -> 5 000,> 5 000

Heavy concrete 130, 80

Concrete of average density 100, 60

Polystyrene concrete 120, 60

Autoclave aerated concrete 10, 6

Lightweight concrete 15, 10

Artificial stone 150, 120

Expanded clay 6-8, 4

Slag concrete 30, 20

Burnt clay (brick) 16, 10

Lime mortar 20, 10

Drywall, Gypsum 10, 4

Gypsum plaster 10, 6

Cement sand plaster 10, 6

Clay, sand, gravel 50, 50

Sandstone 40, 30

Limestone (depending on density) 30-250, 20-200

Ceramic tiles ∞, ∞

Metals ∞, ∞

OSB-2 (DIN 52612) 50, 30

OSB-3 (DIN 52612) 107, 64

OSB-4 (DIN 52612) 300, 135

Chipboard 50, 10-20

Linoleum 1000, 800

The substrate under the laminate plastic 10 000, 10 000

The substrate under the laminate tube 20, 10

Polyfoam 60, 60

EPPS 150, 150

Polyurethane solid, polyurethane foam 50, 50

Mineral wool 1, 1

Foam glass ∞, ∞

Perlite panels 5, 5

Perlite 2, 2

Vermiculite 3, 2

Ecowool 2, 2

Expanded clay 2, 2

Tree across the fibers 50-200, 20-50

It should be noted that the data on the resistance to movement of steam in our and “there” are very different. For example, foam glass is standardized here, and the international standard says that it is an absolute vapor barrier.

A lot of companies produce mineral wool. This is the most vapor permeable insulation. According to international standards, its vapor permeability resistance coefficient (not to be confused with the domestic vapor permeability coefficient) is 1.0. Those. in fact, mineral wool is no different in this respect from air.

Indeed, it is "breathing" insulation. To sell mineral wool as much as possible, you need a beautiful fairy tale. For example, that if you insulate a brick wall outside with mineral wool, it will not lose anything in terms of steam penetration. And this is absolutely true!

The insidious lie lies in the fact that through brick walls 36 centimeters thick, with a difference in humidity of 20% (on the street 50%, in the house - 70%) about a liter of water will leave the house in a day. While with the exchange of air, should come out about 10 times more, so that the humidity in the house is not increased.

And if the wall is insulated from the outside or from the inside, for example, with a layer of paint, vinyl wallpaper, thick cement plaster, (which is “the most common thing”), then the vapor permeability of the wall will decrease by several times, and with complete insulation - tens and hundreds of times .

Therefore, it will always be absolutely the same to a brick wall and to households, whether the house is covered with mineral wool with “raging breath”, or “sad-sniffing” foam.

Making decisions on the insulation of houses and apartments, it is necessary to proceed from the basic principle - the outer layer should be more vapor permeable, preferably at times.

If for some reason it is not possible to withstand this, then it is possible to separate the layers with a continuous vapor barrier, (apply a fully vapor-proof layer) and stop the movement of steam in the structure, which will lead to a state of dynamic equilibrium of the layers with the environment in which they will be.

if the insulation is not placed correctly or the type is chosen, condensation may be formed in the wall or on the wall border with insulation, thus reducing the life time (frost resistance) of the wall material

below are examples of calculations

Что бы оставить комментарий войдите

Комментарии (0)