Everyone who has worked with drywall, is well aware that two of these repairs should be carried out. However, not everyone has the opportunity to work in a pair with someone or hire an assistant for money. Repair with the help of GKL people often spend their own hands just the same in order to save. However, it is impossible to lift a large sheet to the ceiling or hold it against the wall, without supporting it.

To solve the problem will help lift for drywall. With it, you can carry out repair work yourself. It is clear that such a device also costs money. Let's see how it is advisable to buy a lift and whether it can be done independently.

Content:

A special lift allows you to lift drywall to the desired height and fix it in the desired position. All this is done without any significant effort. Special mechanism will significantly save time for repairs. Also lift for gypsum plasterboard is used to transport plasterboard sheets on the working room. Particularly relevant is the use of this device in apartments with high ceilings.

Do not think that the data mechanism uses only once. It can also be used for the following purposes:

The weight of a gypsum plasterboard varies from 17 kg (small ceiling sheet) to 36 kg (a large sheet of moisture-resistant drywall). Therefore, the lifting capacity of the lift should be 50 kg so that there are no problems.

Lifts are wall, ceiling and universal.

In some models, the load capacity reaches 100 kg. This is convenient if you need to carry 3-4 sheets, but such a lift for plasterboard will be more expensive. Usually the device itself weighs no more than 35 kg and can lift the sheet to a height of 4.5 meters, which is more than enough.

A keen eye helps solve various problems.

The device structure and small dimensions allow it to be used in any premises.

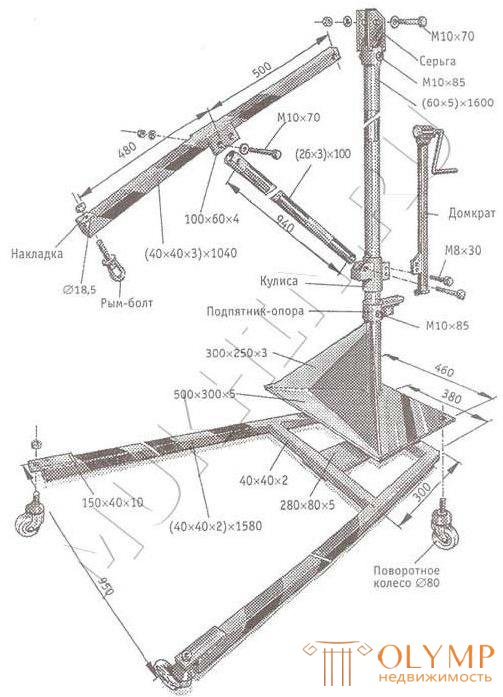

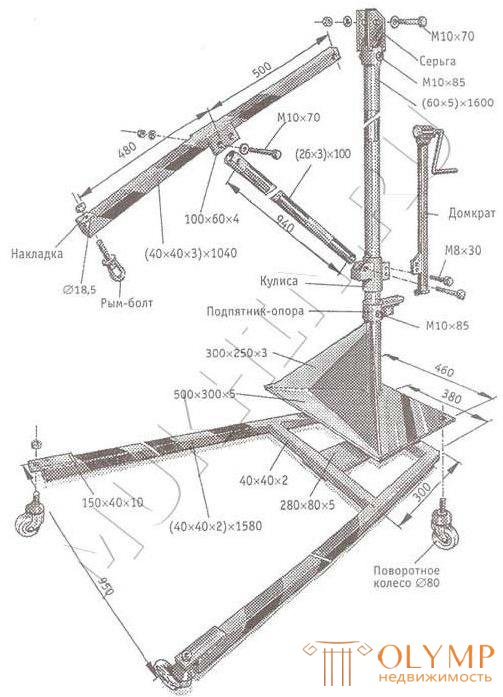

Consider how to make a lift for drywall with your own hands. To do this, you need to understand what parts this mechanism consists of.

The design of the lift may have additional elements depending on its complexity and functionality. Some craftsmen prefer to work with the electric drive to control everything with the help of the remote control, rather than turning it manually.

The size and name of the main elements of the lifting mechanism

The simplest design is the lift strut for drywall. One part of it rests on the floor, and the sheet is laid on the second. Then the tripod lengthens, and the sheet rises and presses against the ceiling.

To create a lift for the installation of drywall do it yourself, you will need to buy a number of metal parts that you will need to weld together. So waste cannot be avoided, but the skills of the welder and the appropriate equipment for the work are also needed.

The first thing you need is a tripod. For this, a profile tube of 60 * 60 mm or 80 * 80 mm is welded in such a way that three legs are obtained. A wheel and a stopper are attached to the end of each leg.

To create a telescopic tripod, you need three shaped tubes of different cross-sections:

In this embodiment, a homemade lift for drywall will fold down and fold up. The tubes are inserted one into one, and plugs are installed, so that the tripod does not fall into itself. At the very top of the pipe you need to weld the plate for mounting the turntable.

Of the three pieces of pipe, the letter “H” is welded so that a sheet of drywall can lie on it. The central web should have two through holes. Props will be inserted into these holes parallel to the two strips of the letter “H”. The props will fix the drywall sheet so that it does not fall, and with their help you can work with small pieces of plasterboard.

Drawing elevator for mounting drywall

The supports are inserted into the previously drilled holes, and then welded or fastened in another way.

The turntable must be attached to the telescopic stand. You can weld it (undesirable, because the design will be cumbersome), and you can attach it to the bolts. For a drywall elevator to be more functional, it is desirable to use a turning mechanism for the table. Then the gypsum board can be fixed to the ceiling and wall, and will also be convenient to lift it.

Turntable is well suited for sloping ceilings.

The winch will have to be bought separately and attached to the entire assembled structure.

There is no point in trying to assemble the GCR lift yourself if there are no specific engineering skills. In principle, you can do without welding, but then you will need to fasten everything on the bolts. This will make the structure not very durable, but for one-time use it will fit perfectly.

Purchase of all components and their further assembly does not guarantee obtaining a quality lift. Again, you need to buy a lot of items and spend time with the forces for their assembly. Moreover, you need to know what kind of metal and in what form it will be needed.

Perhaps it still makes sense to buy a lift for drywall or find an assistant. Moreover, even if you have a lift, he still will not lift the sheet from the floor. And putting a sheet on the table is not an easy task . So even with the lift it will be difficult to work without a partner. Unless you do not need to keep the GLK with your hands above your head while your partner fastens it to the frame.

It makes sense to think about renting a lifting mechanism, since buying is too expensive, and collecting is very difficult.

Что бы оставить комментарий войдите

Комментарии (0)