The first characteristics of the white willow rod are given after its external inspection. According to the requirements for a willow rod intended for weaving, it must be straight, with a smooth and clean glossy surface, without visible dents and damage, insect and disease. It should not be mold or stains of other origin.

This does not mean, of course, that a rod having a slight natural or acquired (without a break) bend, or a rod slightly touched by mold or with some other insignificant flaws, should be thrown out mercilessly. That would be an unaffordable luxury. Let it be a rod of the second or third grade according to your classification, and its use will also be appropriate. This remark will apply equally to almost all the characteristics of the rod.

Grumpiness. Knots can cause a fracture, they interfere with splitting the rod into tires, spoil the appearance of the product. There are years with such weather conditions, when almost the entire rod branches. This is observed, for example, when May and June are arid (the rod grows slowly), and then rainy July comes (as if the awakened rod begins to form new shoots at almost every leaf). Of course, in a cultural plantation, timely watering and fertilizing this can be avoided, but the wild willow is subject only to nature.

The size of the core. It should not exceed, as already mentioned, one third of the diameter of the rod. The big core happens at lushly growing rods on especially fertile and damp soils. The rod in this case is loose, mildy, therefore its area of application is sharply limited. However, it does not follow from this that a rod with a large core can be completely neglected. It is suitable for chess and square weaving, which we will talk about, you can get a very thin ribbon from it and use it even in some cases when an elastic rod with a thin core is inapplicable.

Colour. Since the willow rod consists mainly of cellulose, which is not colored by itself, the natural color of the dried rod is white with insignificant shades. After provocation, the rod acquires cream tones, the saturation and uniformity of which depends on the conditions of boiling and drying. In many ways, the color depends on the willow breed. In advanced farms for the removal of willow, this circumstance is necessarily taken into account. Experienced “ivesavedy” by crossing different breeds achieve a whole range of color shades of the rod.

Shrinkage. The willow rod, which contains moisture in its cells and pores, decreases as it dies along the fibers, i.e., along the length of the stem, and across - along the radius of the cross section. Along the fibers, this change is insignificant and amounts to 0.1-0.3%. The thickness of the rod is sometimes reduced by up to 5%. This circumstance must be taken into account by the weaver. The weaving in the product must be dense, otherwise, after drying, the weft rods begin to move along the bases - the strength and quality of the product decrease.

Easing , or tapering. This is the ratio of the difference in diameter at the beginning and end of the rod to its length, expressed as a percentage. A rate of 0.5% is considered normal or acceptable. With this escapability, the diameter of the rod is reduced by 1 mm every 20 cm.

Dimensions of an unrooted rod with normal escaping, cm: | |||||

| Rod length | 50 | 100 | 150 | 200 | 250 |

| Diameter in butt | 3.5 | five | 7.5 | ten | 12.5 |

This data and data can be used as a guideline for assessing the quality of the rod with respect to runaway. Naturally, the thinner the rod, the less it escapes and the more valuable it is for weaving. Prun with little escapes in Central Russia and the Volga region is called the pursuit. However, rods with great escapability should not be neglected. They can be used in layer-by-layer weaving for the manufacture of product basics and in other cases. The unevenness of the length of the rod unevenness. How it changes can be traced on five long twigs of a three-peeled willow. Their escaping in barked and unrounted form in each is given in the table.

Ordinal number of the rod | Indicator | View rod | Distance from the base of the rod, m | Total rod length | |||||

0 | 0.5 | one | 1.5 | 2 | 2.5 | ||||

| one | Diameter, mm | Green | sixteen | 14 | 12.8 | eleven | 9 | 5.3 | 2, 85 |

| White | 14, 5 | 12.7 | 11.5 | ten | 7,6 | 4.7 | |||

| Easing,% | Green | - | 0.4 | 0.24 | 0.36 | 0.4 | 0.74 | ||

| White | - | 0.36 | 0.24 | 0.3 | 0.48 | 0.58 | |||

| 2 | Diameter, mm | Green | 13.4 | 13.6 | 11.8 | ten | 7.5 | 3.1 | 2, 57 |

| White | 12 | 12 | 10.6 | 8.7 | 6.2 | 2.5 | |||

| Easing,% | Green | - | 0.04 | 0.36 | 0.36 | 0.5 | 0.88 | ||

| White | - | 0 | 0.28 | 0.38 | 0.5 | 0.74 | |||

| 3 | Diameter, mm | Green | 14.5 | 12.5 | 11.8 | 9 | 6.8 | - | 2.41 |

| White | 13.3 | 11.3 | ten | 7,8 | 5.3 | - | |||

| Easing,% | Green | - | 0.4 | 0.14 | 0.56 | 0.54 | - | ||

| White | - | 0.4 | 0.26 | 0.44 | 0.5 | - | |||

| four | Diameter, mm | Green | 12.6 | eleven | 9.9 | 8.7 | 5.5 | - | 2.44 |

| White | 11.5 | ten | 8,8 | 7.0 | 4.8 | - | |||

| Easing,% | Green | - | 0.32 | 0.22 | 0.24 | 0.64 | - | ||

| White | - | 0.3 | 0.24 | 0.36 | 0.44 | - | |||

| five | Diameter, mm | Green | 11.2 | 10.4 | 9 | 7 | - | - | 1.97 |

| White | 10.5 | 9 | 7.7 | 5.6 | - | - | |||

| Easing,% | Green | - | 0.18 | 0.28 | 0.4 | - | - | ||

| White | - | 0.3 | 0.26 | 0.42 | - | - | |||

These tables, of course, have an error. The fact is that it is almost impossible to accurately measure the diameter of the rod, since the rod, especially if it is not rooted, does not always have a circle shape in cross section. But some regularities, and we are primarily interested in runaway, can be clearly seen: in the beginning and in the middle the rod is always more pursuit, its bark is thicker. By the top, the runaway increases, the bark becomes thinner, and rod 2, as can be seen from the table, in an unrooted form, after 0.5 m, it became even thicker than at the cutting point of the butt.

Chasing the rod always grows from low-cut hemp or straight from the root, on sandy soils. On the fat fertile soils, the rod is often stocky, runaway.

Splitting. The general definition is: this is the ability of wood to prick along fibers into pieces. For willow, this property is very important. Splitting the rod into shares (tires) and stripping the ribbon out of them, the weaver receives excellent material for weaving.

Viscosity. A viscous rod is primarily a soft, easily weaveable and shape-retaining rod. Craftsmen like to work with a viscous rod, so they try to increase its viscosity due to pretreatment: moistening, withering, picking willow of a certain breed.

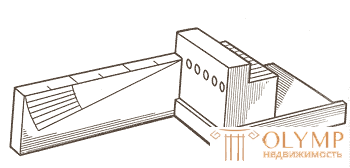

The viscosity of willow of various breeds fluctuates quite significantly. To viscous species can be attributed to the prutovidnuyu and purple willow, and to non-viscous - American. In the book of LF Pravdin "Willow, its culture and use" a method is described for determining the viscosity of a rod according to the method of A. P. Glagolev using the device shown in fig. 1. It consists of a board with planks at the edges, which do not allow a cube with holes to go to the sides. A second board up to 30 cm in length is vertically attached to the left edge of the board, on which an arc graduated scale is applied (from 1 to 10R). On the upper edge of the vertical board there is a linear scale from 1 to 30 cm. On the horizontal board is placed a wooden cube with holes with a diameter of 2.5 located in the same horizontal plane; 3.5; 4.5; 5.5; 7.5 mm. The middle of these holes should coincide with the upper edge of the vertical board. For the convenience of working with a rod, half of the upper part of the cube is cut along a plane that cuts the holes in half.

Viscosity is defined as follows. The rod under test is inserted tightly into the hole of the smallest diameter strictly parallel to the upper edge of the vertical board! At a distance of 20 cm from the hole on the rod put on a light cardboard cup scales, which gradually impose a load until the end of the rod does not deviate by 10R (on a scale on a vertical board). The greater the viscosity of the rod being studied, the less will be the load to deflect it by 10R.

After determining the viscosity of the rod inserted into the hole of the smallest diameter, the rod is transferred to the next largest hole and again determine the load that deflected it on 10R on a scale on a vertical board. The thicker the rod, the greater must be the load (in grams) for its deviations by an equal amount and the less its viscosity (Fig. 2).

| Fig. 1. A device for determining the viscosity of the rod |

|  |

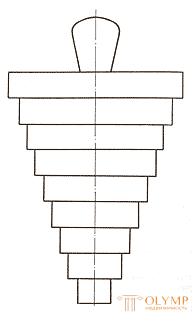

| Fig. 2. Curve rod viscosity | Fig. 3. A device for determining the flexibility of the rod |

Flexibility. This indicator is most important for the rod. Flexibility is the property of the rod to withstand bends without breaking or forming folds. To determine the flexibility, you can use the device shown in Fig. 3. It is easy to turn out of wood. The diameter of the upper stage 50 mm, lower 10 mm, gradation after 5 mm. By the way, the same device can be used as a template for bending ring details of small diameter.

They take 20-25 identical rods of willow of the same breed, and each of them is alternately wound with a thin end, first on the step with the maximum diameter, then on the step below, and so on, until the rod breaks. When all rods are tested, calculate the arithmetic average diameter at which the rod breaks. You can choose your own units to characterize the technical properties of the rod, as well as come up with the appropriate devices.

Что бы оставить комментарий войдите

Комментарии (0)