Such pre-stressed elements are such reinforced concrete elements in which previously, i.e. during the manufacturing process, the initial tensile stresses in the working reinforcement and compression of the concrete are artificially created in accordance with the calculation. The compression of concrete in a pre-stressed structure for a given amount of Gвр is carried out by a pre-tensioned reinforcement, which tends to return to its original state after the release of tensioning devices.

At the same time, due to frictional forces, the reinforcement is retained in the concrete, and in case of insufficient adhesion of the reinforcement to the concrete, special artificial anchoring of the ends of the reinforcement in the concrete is used.

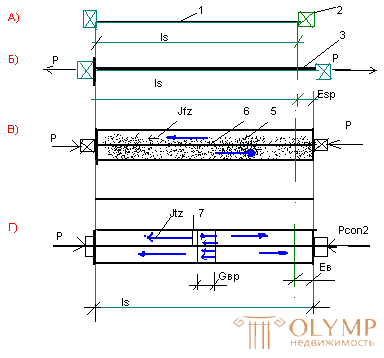

“A” - rebar preparation.

"B" - exhaust fittings.

"In" - release tensioning devices.

"G" - the elastic compression of concrete.

1- Armature of original length ls.

2- Additional anchor at the ends of the reinforcement (if necessary)

3- Specified by the calculation of the elongation of reinforcement Esp

4- Force P causing the specified elongation of reinforcement.

5- Concrete - the strength of which at the time of tension release is = 70% Rвp

6- Armature, seeking to take the original position, after the release of tensioning devices.

7- Length of reinforcement after compression of concrete EV

The stress state at the prestressing of reinforcement concrete is compressed, and the reinforcement is stretched

The purpose of prestressing is to compress the concrete in those areas of the structure where tension will occur under load.

Stretching reinforcement is only a means for compressing concrete.

The tensile stresses arising during the work under load only cancel out the preliminary compression of concrete, and therefore the formation of cracks is significantly removed. Consider stress plots in prestressed structures:

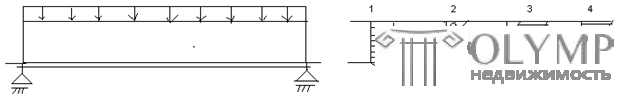

1. The stress diagram with precompression.

2. Plot of stress load.

3-4. Total stress diagrams.

We see that the operational loads that cause tensile stresses in any zone of concrete will be folded with the previously created compressive stresses.

Concrete begins to work in tension only after the full reduction of the preliminary compression, but by this time the entire operational load is already applied to the element, therefore the crack resistance of the structure with the reinforcement prestressing is much higher than the crack resistance of the same structure without preload.

ADVANTAGES:

1. In prestressed structures, it is possible to use highly economical reinforced bar reinforcement and high-strength reinforcement. Pre-compression of the stretched zones of concrete significantly alienates the moment of formation

cracks in the stretched zones of the elements, limits the width of their disclosure and increases the stiffness of the elements.

2. Pre-stressed structures are often economical for buildings with such spans, loads and working conditions under which using reinforced concrete structures without prior stress is technically impossible or causes an excessively large waste of concrete and steel to provide the required rigidity and bearing capacity of structures.

3.Pre-tension of structures allows to expand the use of prefabricated and precast-monolithic structures of steel section, in which reinforced concrete is used only in prefabricated pre-stressed elements, and most of the structures are made of heavy or lightweight concrete that is not subjected to pre-stress.

4. Increased endurance of structures when working on the impact of repetitive loads.

5. The metal content of structures is increased - this is due to the fact that, thanks to the use of more durable and lightweight materials, the cross sections of prestressed structures turn out to be smaller compared to reinforced concrete structures without prestressing, and therefore more flexible and lightweight.

LIMITATIONS.

1. Pre-tensioned structures are characterized by increased complexity of design and manufacturing. They require greater care in the calculation and design, in the manufacture.

For example, at the ends of prestressed structures, with a concentrated application of compression forces, longitudinal cracks may occur, significantly reducing their carrying capacity. If you do not take into account the specifics of the creation of pre-stress, the working conditions of the load of the entire structure or its individual parts may deteriorate.

High efforts transmitted by reinforced reinforcement to the concrete structure at the time of tensioning devices release can lead to its destruction in the process of crimping or local damage, to slipping of the reinforced reinforcement due to the violation of its adhesion with concrete. Therefore, the standards require to check the strength of prestressed structures in the stage of compression, during storage, installation.

Pre-stressed structures require complication and increase in metal intensity of formwork, labor intensity of reinforcement, increase in metal consumption for embedded parts and reinforcement.

2. Pre-stressed structures are fireproof, but their fire resistance is lower than that of reinforced concrete structures without prestressing. This is due to the fact that critical temperatures, to which safe preheated reinforcement can be safely heated, are lower compared to non-stressed reinforcement.

3. Pre-stressed structures are characterized by insufficient corrosion resistance. Corrosive lesions dramatically reduce the carrying capacity and plastic properties of high-strength reinforcement, cause cracking of thermally-reinforced reinforcement, which causes the brittle fracture of prestressed structures. In order to increase the corrosion resistance, it is necessary to use dense and waterproof concrete on special sulphate-resistant cements, surface protection with polymeric materials, plaster, taped-in or coating insulation; increase the protective layer of concrete to 25 mm.

Что бы оставить комментарий войдите

Комментарии (0)