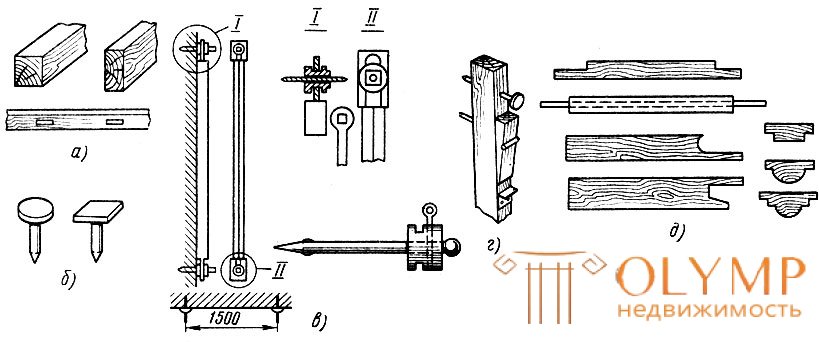

The rules (Fig. 13, a, d) are planks or bars of different lengths and sections, planed or fugated. The rules for checking the accuracy of the made plaster are made from a board 100mm wide with one cutout or two for the hands. Simple rules are also used when stretching eaves and pallets, finishing window and door slopes, plastering beams, pilasters, pillars, leveling mortar on different surfaces by beacons. If the working part of the rule is upholstered with flat steel, this will prevent the rule from warping, in addition, sharp steel burrs better cut off the solution.

Steel grades (fig. 13, b) - thick short steel nails from 50 to 70 mm long, up to 10 mm thick, with square or round caps with a diameter of at least 30 mm. They are used instead of mortar marks in the device beacons. Steel grades are easily hammered into the seams of brick and other masonry, as well as slag concrete and other difficult to nail surfaces.

Lighthouses are mortar, wooden and metal. Mortar beacons are the most laborious. (Their device is described in § 16.) Wooden beacons are slats-rules with a section from 40 x 40 to 50 x 50 mm.

Inventory metal lighthouses (Fig. 13, c) are made of steel, aluminum or other hard corners with a cross section of 25 x 25, 30 x 30 and 35 x 35 mm. With their help, plaster is applied with a thickness of 18, 22 and 25 mm respectively. The working part of such lighthouses is the top of the corner - the usenok. The kerchiefs are welded to the ends of the corners with cuts 60-70 mm long, in which the steel pin with a nut moves. The nut can either rotate along the thread on the pin, or move along the pin and be fixed on the pin with a screw. So that the nut does not slide off the pin and is not lost, a widening or notch is made at its end. It is recommended to unscrew the screw so that it does not twist out. The kerchief cuts are needed in order to move them over the nuts (up or down) when fastening the pins in the masonry when the distance between the seams is not the same. The length of the lighthouse should be 100 mm shorter than the height of the walls of the room to be plastered.

Fig. 13. Adaptations: a, d - rules, b - steel grades, in - inventory metal beacons, d - malka

Malki (Fig. 13, d) is used for leveling the solution between the wooden beacons on the walls, ceilings, slopes, zaglushinakh. For leveling the mortar between wooden beacons that are greater than the thickness of the plaster, simple or sliding pulleys with cutouts of a depth that corresponds to the thickness of the mortar are used. Sliding pullers make it possible to level the solution between beacons located at a distance of 1.2 to 2 mm.

Malki for leveling the solution on the slopes and zaglushinah make small sizes with cuts at one or two ends. For leveling the solution in the deafers, flat pullets are used for the upper and lateral sides and rounded or flat simple and with a hanger for the lower blind. Malki can be shackled with steel.

Clamps (see fig. 40) are intended for fastening rules to surfaces. Simple clamps fix the rules when pulling out the drapes, finishing window and door slopes. They consist of a square or rectangular pin with a length of 150 to 200 mm and a foot with a hole in the shape of a pin, which is put on the pin. Difficult clips consist of a pin, bracket and two screws. The pin is driven into the surface, put a bracket on it, fasten it to the pin with a screw, put a rule in a bracket or a wooden beacon and fix it with another screw.

Templates are used to pull out the eaves (corbels, belts, platbands). They come in different sizes and designs. The fabrication of templates is described in ch. Ix.

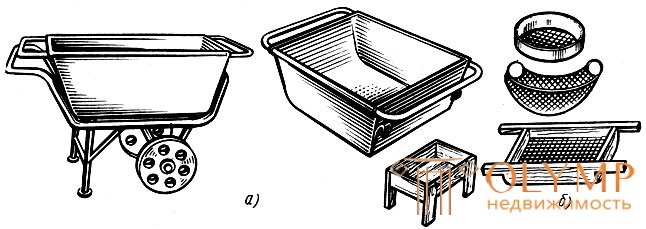

Mortar boxes (Fig. 14, a) are intended for the preparation and storage of dry mixtures and solutions. They are wooden and metal.

Fig. 14. Inventory: a - mortar boxes, b - sieve

The most convenient inventory metal boxes-carts. They consist of a trolley with a handle, two legs and two wheels, onto which removable boxes with a capacity of up to 0.1 m3 are installed. Box dimensions, mm: length 1000, width 525, height 300. The mass of the trolley with the box is 26.3 kg. The box from which the entire solution is selected is replaced by another one filled with a solution.

If there are no inventory, then use wooden boxes of different sizes, but a depth of no more than 200 mm, so that it is convenient to recruit a solution from it and prepare portions of lime-gypsum mortar in it. The boxes are knocked out of boards no more than 25 mm thick. At the bottom of the box the boards are placed along the length. The box is installed on legs with a height of 600-700 mm, and the front ones are made 30-50 mm shorter. Slope in the box is necessary for the solution to flow in one direction.

To work with a liquid lime-gypsum mortar, the box is partitioned off with a board so that the solution does not flow down and there is room for making plants. In a wooden box, the board is fastened with nails, in a metal box with a wedge.

Sieves (Fig. 14, b) are used for sifting bulk materials and filtering solutions. The sieves can be pulled on a round holder (shell), or tied onto a rectangular wooden frame with handles, or simply to tie up the ends of the grid, tie them with matting or cloth.

Что бы оставить комментарий войдите

Комментарии (0)