The fight against high humidity in industrial premises is as old as the world, since it tends to accumulate in the elements of upholstered furniture and condense on the equipment, repeatedly intensifying the processes of corrosion of materials. Moisture can also appear on the walls, flowing from which will form puddles on the floor, which is unacceptable from the point of view of safety, and has a negative effect on the microclimate of the room itself.

In many cases, it is sufficient to simply ventilate the room to reduce the humidity in the production workshops, but this is not always possible, and this procedure may not give the desired results due to the high humidity of the outdoor air. In addition, during the cold season, due to ventilation, not only moisture but also heat is removed from the room.

Industrial air dryer will solve this problem without any special energy and labor costs. In the production premises, it will relieve window misting, mold and fungi, as well as damage to equipment and finishing materials. Also, industrial dehumidifiers are used in construction and repair works. Reducing the humidity in the room contributes to a significant improvement in the quality of the finishing works. In particular, this procedure is useful before installing the floor screed and laying the floor covering on it, as well as before facing the walls, in order to avoid moisture accumulation under the finishing materials.

In another field of application, industrial dehumidifiers are widely used - this is a decrease in the level of humidity in swimming pools, to create a comfortable microclimate for visitors and staff, and also for the preservation of materials in the room. There is a great need to reduce humidity in compressed air distribution systems, which leads to the formation of condensate in pipelines.

To date, four types of dehumidifiers are used to dry the air in the workshops:

Membrane are both wall-mounted and mobile - that is, portable. The most common dryers for swimming pools are channel-type units.

The principle of the adsorption device is based on the property of certain substances to absorb moisture from ambient air, the flow of which passes through an adsorbent with a high level of moisture absorption, after which it is heated and fed back into the room. This rather simple unit has advantages and disadvantages. The advantages include:

The principle of the adsorption device is based on the property of certain substances to absorb moisture from ambient air, the flow of which passes through an adsorbent with a high level of moisture absorption, after which it is heated and fed back into the room. This rather simple unit has advantages and disadvantages. The advantages include:

The main disadvantage of an industrial drying device based on this principle is the relatively high cost of the adsorption material, which periodically needs to be replaced with polluted air.

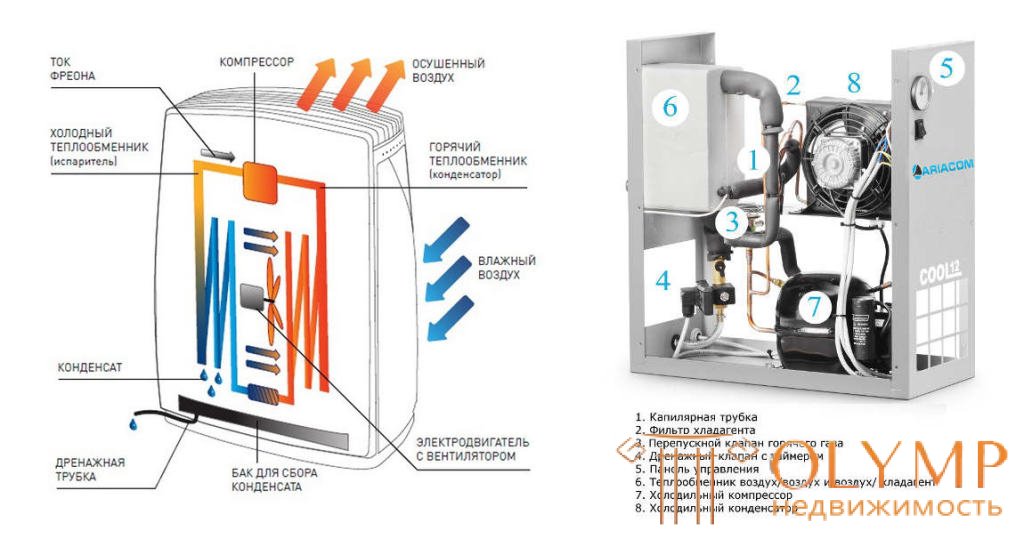

Condensation industrial drying devices are based on the phenomenon of condensation of moisture on chilled surfaces. The air, under the action of the fan passes through a cooled heat exchanger, on which moisture settles as condensate. After which the dry air passes through a heated heat exchanger, where it is heated and fed back into the room. Moisture accumulating in the device is condensed on a cold surface and removed using a special tray. The industrial refrigeration dryer also has advantages and disadvantages, namely:

The main disadvantage of refrigerator-type devices is their efficiency, only in rooms with relatively high temperatures.

Dryers operating on this principle are rarely used due to the high cost of chemical adsorbents. The principle of operation of these units, similar to the adsorption devices to reduce humidity in the production shops, with only one difference: In delicately dryers, the adsorption substance, absorbing moisture, turns into liquid itself, and then is discharged through the condensate drain valve. Soluble elements having such properties and used as adsorbing materials are special tablets made on the basis of sodium or calcium salts. Advantages of using these dryers:

The main disadvantage of using these devices is the high cost of consumables and their regular maintenance.

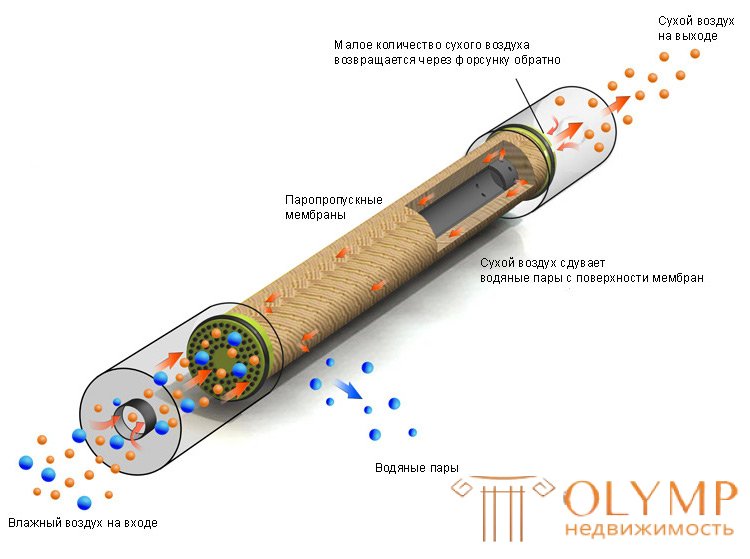

Specially designed membranes installed in these devices pass only water vapor through themselves, and do not let air through. Thus, at the outlet of the device the air flow has a much lower humidity than at the entrance. The advantages of the device:

Specially designed membranes installed in these devices pass only water vapor through themselves, and do not let air through. Thus, at the outlet of the device the air flow has a much lower humidity than at the entrance. The advantages of the device:

Disadvantages of membrane dryers:

When the ambient air is compressed, its temperature rises, and thus the concentration of water vapor increases. When entering the distribution system, the air condenses in the pipeline, which leads to its premature failure, due to corrosion and various sediments formed under the influence of condensate. Some enterprises use purge lines and distribution pipelines.

The effectiveness of this method is questionable, due to the complex structure of distribution channels. To remove moisture from these systems, industrial compressed air dryers are used, which can be of all the types listed above.

First of all, the right choice of this unit should be made by an expert, based on data on humidity deviation from the established sanitary standards, the type and size of the structure, as well as its temperature indicators. It is also necessary to consider the possibility of ventilation of this room . The second important issue is the choice of equipment that will fully comply with the indicators declared by the manufacturer: throughput capacity in m3 and “dew point”.

The right choice of industrial dehumidifier will allow you to solve the problem of high humidity in the production shops and establish a healthy microclimate, contributing to an increase in the productivity of workers.

Что бы оставить комментарий войдите

Комментарии (0)