The method of utilization of the luminous flux is used to (calculate the total uniform illumination of horizontal surfaces with lamps of any type.

The essence of the method is to calculate the coefficient for each room, based on the basic parameters of the room and the reflective properties of finishing materials. The disadvantages of this method of calculation are the high complexity of the calculation and low accuracy. This method is the calculation of indoor lighting.

The illuminated volume of the room is limited to the enclosing surfaces, reflecting a significant part of the luminous flux falling on them from light sources. In indoor installations, reflective surfaces are the floor, walls, ceiling and equipment installed in the room. In cases where the surfaces limiting space have high values of reflection coefficients, the reflected luminance component can also be of great importance and its accounting is necessary, since the reflected flows can be comparable to straight lines and their underestimation can lead to significant errors in the calculations.

In the process of performing the calculation part it is necessary:

a) choose the lighting system, light source, type of luminaire for a given area or workroom;

b) calculate the total lighting of the working room.

The purpose of the calculation of general illumination is to determine the number of luminaires needed to provide Emin and the power of the lighting installation necessary to provide in the workshop the normalized illumination. The calculation of total illumination using the luminous flux utilization method is described below.

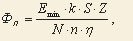

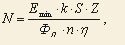

When calculating according to the specified method, the required luminous flux of one lamp is determined by the formula:

or the number of lamps:

where Emin is the minimum normalized illumination, lx;

k is the safety factor (for incandescent lamps, k = 1.15, for luminescent and DRL, DRI and DNaT lamps, k = 1.3);

S - illuminated area, m2;

Z is the coefficient of minimum illumination (coefficient of uneven illumination) (when calculating the illumination from luminaires with incandescent lamps , DRL , DID, and DNaT Z = 1.15, with fluorescent lamps Z = 1.1);

N is the number of lamps;

n is the number of lamps in the lamp;

h is the coefficient of use of the luminous flux in fractions of a unit.

The power of the lighting installation P is determined from the expression:

where Pi is the power consumption of one lamp, kW.

Recommended calculation algorithm

It is recommended to calculate the total illumination in the following sequence:

1. Choose a lighting system.

2. Justify the normalized illumination in the workplaces of a given object.

3. Choose an economical light source.

4. Choose a rational type of lamp.

5. Estimate the luminosity safety factor, k , and the irregularity coefficient of illumination, Z.

6. Estimate the reflection coefficients of surfaces in the room (ceiling, walls, floor), r .

7. Calculate the room index i .

8. Find the utilization of the luminous flux, h .

9. Calculate the required number of luminaires, N, or the luminous flux of the lamp, FL , which are necessary to ensure the required illumination Emin at the facility.

10. To perform a sketch of the location of the lamps on the floor plan with an indication of the size.

Principles of selection of the main elements necessary for the calculation

Choosing a lighting system

In this paper, we consider only working lighting, which can be general and combined. The device in the production areas only local lighting is prohibited.

The choice of the lighting system depends primarily on such an important factor as the accuracy of the visual work performed (the smallest size of the object of discrimination), according to the current standards when performing work I-IV discharges, you should use a combined lighting system. In mechanical, instrumental, assembly, etc., as a rule, a combined lighting system is used. In foundry, electroplating, etc. workshops - general lighting system.

The choice of the lighting system is made simultaneously with the choice of the normalized illumination.

Choice of normalized illumination

Quantitative and qualitative indicators of artificial lighting are determined according to the current standards [1].

The smallest illumination of the working surface Еmin , which depends on the discharge of visual works, the background and contrast of the object with the background and the lighting system, is taken as a quantitative characteristic of the illumination .. The discharge of visual works is determined by the minimum size of the object of discrimination, i.e. the size of the object, its part or defect on it, which must be detected or distinguished in the process of production activity.

Quality indicators of illumination (ripple coefficient and glare index) are not considered in this work.

You can take the value of Emin for accurate work III discharge 300-500 lux, for average accuracy IV discharge 150 -300 lux, for works of low accuracy V discharge 100 -150 lux. Smaller light value in each digit for a light background and high contrast, more for a dark background and low contrast. In tab. 3 appendices show the Emin values for all discharges of visual works and various contrasts.

Selection of light sources

The determining parameters when choosing an economical light source are the construction parameters, the architectural - planning solution, the state of the air environment, design issues and economic considerations.

When designing lighting, the designer always makes a compromise decision.

General recommendations are given in the literature [2].

Incandescent bulbs are of low economic efficiency, they have a light output of 7–26 lm / W, they have a distorted emission spectrum, and during operation they become very hot. But, on the other hand, they have a low cost, are easy to operate and can be recommended for rooms with temporary stay of people, domestic premises, etc.

The main advantage of fluorescent lamps is their high light output, up to 75 lm / W and a service life of up to 10,000 h, good color rendition, low temperature. Although they are expensive, they require specialists for their maintenance, they have complicated starting equipment, sometimes they make noise, they blink, and problems arise when they are disposed of.

In rooms up to 6 m is recommended to use fluorescent lamps.

In industrial premises with a height of up to 7–12 m, it is advisable to use DRL type lamps, since They are more powerful and have a higher light output of up to 90 lm / W.

Promising are metal halide lamps of high pressure type MGL.

The final choice of the light source must be made simultaneously with the choice of the type of luminaire of which it is a part.

Lamp selection

The choice of general lighting fixtures is made on the basis of accounting for lighting, economic requirements, and conditions of the air environment. There is a classification of luminaries according to the light distribution: direct, mostly direct, diffused, mostly reflected and reflected light.

In addition, there are lamps with different light intensity curves: concentrated, deep, cosine, semi-wide, wide, uniform and sine.

According to GOST 14254-69, lamps are classified according to the degree of protection against dust, water and an explosion.

According to the design, according to [1], there are 7 operating groups of luminaires. In view of the extraordinary diversity of luminaires, a specific choice of luminaire should be decided in conjunction with energy experts, economists, designers, and taking into account labor protection requirements, or refer to special reference books [2] and [3].

Safety factor

The safety factor k takes into account the dustiness of the room, reducing the luminous flux of lamps during operation. The values of the coefficient k are given in the table.

Table The values of the coefficient k

Premises | Examples of rooms | Safety factor k | |

Discharge lamps | Incandescent lamps | ||

Dust content over 5 mg / m3 | Cement plants, foundries, etc. | 2 | 1.7 |

Smoke, soot 1-5 mg / m3 | Forge, welding shops, etc. | 1.8 | 1.5 |

Less than 1 mg / m3 | Tool, assembly shops | 1.5 | 1,3 |

Significant concentration of acid and alkali vapors | Chemical factories, electroplating shops | 1.8 | 1.5 |

Dust content significantly less than 1 mg / m3, lack of acid and alkali vapors | Residential, administrative and office, etc. premises | 1.2 | 1.1 |

Minimum Illuminance Factor Z

The coefficient of minimum illumination Z characterizes the uneven illumination. It is a function of many variables, its exact definition is difficult, but to the greatest extent it depends on the ratio of the distance between the lamps to the design height (L / h).

Choose the method of placement of lamps, which can be symmetrical or localized. With a symmetrical placement of the lamps are located both along and across the premises at the same distance, at the corners of a rectangle or in a checkerboard pattern. Symmetrical placement of lamps provides the same lighting equipment, machines, workplaces and aisles, but requires a large power consumption. With a localized location, the lamps are placed taking into account the location of machines, machines, equipment, places of control and jobs. This arrangement of lamps, reducing energy consumption, is used in workshops with asymmetrical placement of equipment.

Next, determine the ratio of the distance between the lamps L to the height of their suspension h . Depending on the type of luminaire, this L / h ratio at the location of the luminaires by the rectangle can be taken equal to 1.4-2.0, and at the staggered arrangement it is -1.7-2.5.

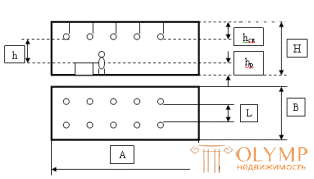

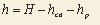

The height of the lamp above the illuminated surface

Hc = H - hcv - hp

where N is the total height of the room, m;

HCV - height from the ceiling to the bottom of the lamp, m;

hр - height from the floor to the illuminated surface, m

In order to reduce the blinding effect of luminaires of general illumination, their height above the floor level is set at least 2.5-4 m with lamps up to 200 W and at least 3-6 m with lamps of greater power.

The required number of lamps (lamps) n = S / L² (with La = Lb).

When luminaries are arranged in a line (row), if the most advantageous L / h ratio is maintained, it is recommended to take Z = 1.1 for fluorescent lamps and Z = 1.15 for incandescent lamps and DRL.

Fig. The location of the fixtures in the room

Light flux h

To determine the utilization factor of the luminous flux h, we find the index of the room i and the estimated reflectances of the surfaces of the room: the ceiling rp , walls rc , floor rp .

Usually for bright office and office space:

rп = 70%,

rc = 50%

rp = 30%.

For industrial premises with minor dust emissions:

rп = 50%,

rc = 30%,

rp = 10%.

For dusty industrial premises:

rп = 30%,

rc = 10%,

rp = 10%.

Room index i

The index of the premises is determined by the following expression:

where A, B, h are the length, width and design height (height of the lamp suspension above the working surface) of the room, m.

where H is the geometric height of the room;

hsv - overhang of the lamp.

Usually hcv = 0.2 ... 0.8 m;

hp is the height of the working surface.

hp = 0.8 ... 1.0 m.

The utilization of the luminous flux is a complex function, depending on the type of luminaire, the index of the room, the reflection coefficient of the ceiling walls and floor. For the most common luminaire with fluorescent lamps, the coefficient h can be determined from the table.

Intermediate values of the utilization factor are found by interpolation.

For complex luminaires, this coefficient can be found in the special reference books [2], [3] and in the appendix to this guide.

For a given Fl , i.e. we know what lamps will be used, we find N , i.e. how many fixtures to apply.

For a given N or n , we define Fl . According to the found Fl choose the nearest standard lamp within the tolerances - 10 ¸ +20%.

Table The value of the coefficient of use of h for lamps with fluorescent lamps,%

I | rп% 70 rc,% 50 rp% 30 | 50 thirty ten | thirty ten ten |

0.5 | 28 | 21 | 18 |

1.0 | 49 | 40 | 36 |

3.0 | 73 | 61 | 58 |

5.0 | 80 | 67 | 65 |

The table shows the calculated values of the luminous flux of the most common light sources Fl

Table The calculated values of the luminous flux of the most common light sources Fl .

Lamp type | FL, LM | Lamp type | FL, LM | Lamp type | FL, LM |

LDC 40-4 | 1995 | LDTS80-4 | 3380 | DRL 80 | 3200 |

LD 40-4 | 2225 | LD 80-4 | 3865 | DRL 250 | 11,000 |

LHB 40-4 | 2470 | LHB 80-4 | 4220 | DRL 1000 | 50,000 |

LTB 40-4 | 2450 | LTB 80-4 | 4300 | DRI 250 | 18700 |

LB 40-4 | 2850 | Lb 80-4 | 4960 | DRI 400 | 32,000 |

LHBTS 40-1 | 2000 | DRI 1000 | 90000 |

An example of the calculation of the premises by the coefficient of use

Example. In a room with a small amount of dust, dimensions A = 21 m, B = 12 m, H = 4.2 m, hp = 0.8 m and the reflection coefficients of the ceiling rp = 50%, walls rc = 30%, the calculated surface rp = 10% shall be determined using the coefficient of use of the luminous flux by illuminating Astra lamps with incandescent lamps to create illumination E = 50 lx.

Decision. In a room with a small emission of dust, an lighting installation with incandescent lamps is calculated with a safety factor of k = 1.3. In the lamp "Astra" cosine light distribution. Therefore, the optimal relative distance between the lamps should be taken λ = 1.6. Taking the height of the overhang of the lamps hcv = 0.5 m, we obtain the calculated height

hp = 4.2-0.8-0.5 = 2.9 m

and the distance between the lights

L = 2.9 × 1.6 = 4.64 m.

The number of rows of lamps in the room

Nb = 12 / 4.64 = 2.58.

Number of lamps in a row

Na = 21 / 4.64 = 4.56.

Round these numbers to the nearest large Na = 5 and Nb = 3.

Total number of fixtures

N = Na × Nb = 5 × 3 = 15.

Place the final fixtures.

The width of the room is the distance between the rows Lb = 4.6 m, and the distance from the outermost row to the wall is slightly more than 0.3L, namely, 1.4 m. In each row, the distance between the lamps will also take La = 4.6 m, and the distance from the last lamp to the wall will be

(21-4,64) / 2 = 2.6 / 3 = 1.3 m.

This is 0.28 L.

Room index

i = 21 × 12 / [2.9 (21 + 12)] = 252 / (2.9 × 33) = 2.63.

According to the directory choose the utilization of the luminous flux η = 0,6. Since the distance between the lamps is almost equal to the optimum, we take the coefficient of minimum illumination z = 1.15. Determine the required luminous flux of the lamp

Fl = 50 × 1.15 × 252 × 1.3 / (15 × 0.6) = 2093lm

According to the table, we choose the nearest standard lamp G215-225-150, which has a flux of Fl = 2090 lm, which is less than the calculated value by ΔФ = (2090-2093) 100/2093 = - 0.14%.

Literature:

1. SNiP II - 4 - 79. Natural and artificial lighting. Design standards. - M .: Stroyizdat, 1980.- 48 p.

2. Reference book on lighting / Ed. Yu.B. Eisenberg -M .: Energoatomizdam, 1983.- 472 p.

3. Reference book for the design of electric lighting / Ed. Gm Knorring. - M .: Energy, 1976. - 384 p.

Что бы оставить комментарий войдите

Комментарии (1)

Задача 1.2. Рассчитать методом коэффициента использования светового потока помещение с малым содержанием пыли и размерами А = 21м, В = 12м, Н = 4,2м, высота рабочего уровня hр=0,8м, высота свеса светильника hсв= 0,4м, создать освещенность Е = 300 лк люминесцентными лампами ЛБ40 в светильниках ЛДОР. Коэффициенты отражения в помещении ρп=50%, ρс=30%, ρр.п=10%, коэффициент запаса кз=1,3.