The need to lay a new electrical cable may arise under various circumstances: major repairs, construction of a new building, changing the layout, etc. In the wall, you can hide any communication, the diameter of which does not exceed a third of its thickness .

The content of the article:

- General rules

- Tool for shtrobleniya walls under wiring

- Shaving process

- Shaving in panel houses

- Switches for switching devices

- Security measures

- A simple example of basic operations for wall chipping

There are several mandatory installation rules for concealed electrical wiring to be performed regardless of the chosen method of shaving, the material from which the wall is made and other circumstances.

Execution of strobes is possible in four different ways. When choosing between them, you should consider the type of wall, tools that are available and a number of other factors.

It is recommended to lay the wiring in the walls of concrete at the initial stage of repair. In areas where people live, the performance of these works is undesirable due to the large amount of dust emitted. If there is no other way out, it is necessary to carefully cover all interior items and use a construction vacuum cleaner when working.

Before making the grooves, you should install the route of the old wiring and remove the voltage from it or bypass these places.

Consider the above-described technology of chroming on the example of working with concrete walls.

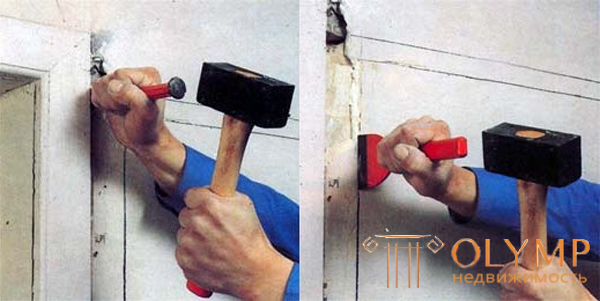

The process of making grooves on concrete walls is simplified due to its breakdown into separate stages. First of all, along the edges of the gate, with the help of a chisel, they make indentations for a width of 1-2 tips. Then, setting the chisel across the grooves, hammer it into the wall. The recess grooves can be made as gradually , removing layer after layer, and immediately drive the chisel to the desired depth. For walls of concrete, this method is the least effective of all because of the high hardness of the material .

Much more effect can be achieved with a punch . Before starting work, you should mark the site .

Shtabing is done with a small drill and a blade-shaped nozzle. Throughout the future grooves drill holes . Their depth is 2.5 cm, and the distance between two adjacent ones is 1-1.5 cm. Then a spatula is installed on the perforator, and placing it along the future roadway , they remove the wall sections between the holes. The tool can not be put across the line, because as a result, excess chips may be formed. Perforator allows you to quickly and accurately perform the strobe the required size. Among the shortcomings can be noted torn edges and not too aesthetic appearance.

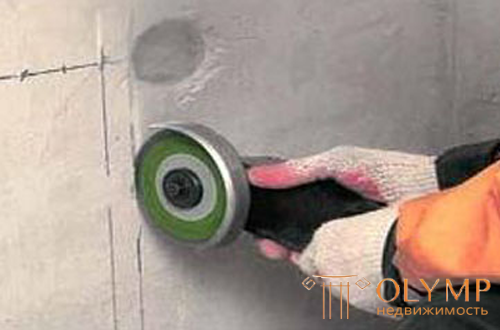

When concrete or brick walls are crushed using the “grinder”, the disk must necessarily have a diamond coating . Conventional nozzles can simply not cope with such durable material. Yes, and when making grooves in plaster, with a diamond disc, things will go much faster.

First, markup is applied to the wall. After that, the outer edges of the grooves make cuts . In fact, the "Bulgarian" just for this and need. The material between the incisions is removed by improvised means — a perforator or a chisel — to the required depth . This method involves the abundant formation of dust, so you should take care of its removal with an industrial vacuum cleaner or cover all the objects in the room.

A wall chaser is a professional tool designed specifically for making grooves. Outwardly, he vaguely resembles a "Bulgarian". The main difference is that two drives are installed on the wall chaser at once . The distance between them can be adjusted according to the desired groove width. The tool is equipped with a casing to trap dust . Its position is also regulated by the required depth of the slits. The casing of some models is equipped with a special outlet to which the pipe of an industrial vacuum cleaner joins.

The process itself takes a little time and effort. The material between the slits is removed with a chisel or perforator. The main drawback is the high cost of the instrument , as a result of which it is unprofitable to purchase it for domestic use. However, a wall chaser can be rented .

At the end of the work, remove debris and construction dust from the finished groove (regardless of the tool it was used with). Then the strobe is ground, the cable is placed into it (or the cable channel through which wires are drawn with steel wire), and the surface of the wall is plastered, plastered or cast.

In brick buildings, joints between adjacent rows of bricks can be chosen as a place for arranging horizontal grooves.

If, when deciding on a tool for shaving, the choice is between a perforator and a grinder, it is recommended to choose the first option. The perforator has more power and is designed to work with hard materials. In addition, when using it, less dust is generated. Determining the time of work, it should be borne in mind that the punch creates a high level of noise.

When drilling holes, it is recommended to periodically moisten the work surface. This will allow no dusting. However, it must be remembered that it is more difficult to make a damp wall.

Professional builders rarely use a wall chaser when working with concrete walls, since after it the grooves still have to be machined with a perforator. Therefore, the punch is usually initially used as the main tool.

Arrangement of strobe in panel houses has its own nuances.

When arranging the grooves for valves, switches and sockets, special nozzles are inserted into the perforator - pockets . The cost of work as a result increases slightly, but additional costs are offset by high efficiency.

However, the deepening can be done with the help of the "grinder", making cuts along the perimeter and removing the middle with a perforator. In this way, in particular, make shafts for distribution boards.

The main harmful factor in chipping is dust. To reduce its negative impact by using the following measures:

There are various options for shtenbing the walls. When choosing between them, it is necessary to take into account the type of surface, the availability of various tools, the estimated budget and other factors, depending on the specific situation. As we see, the easier and quicker the process is, the more expensive the necessary tools are for it. However, excessive saving does not always justify itself: the correction of errors made during the laying of wires can cause considerably more problems than all the repair done.

Aerated concrete, due to its unique qualities - strength, lightness, thermal insulation and the ability to pass air, has gained immense popularity in modern construction.

Processing walls of aerated concrete blocks is much easier than, for example, of reinforced concrete, due to the porous structure of aerated concrete.

Release it in a variety of shapes and sizes. Aerated concrete blocks are convenient for transportation, storage and processing. Build it yourself easily, quickly and cheaply. One of the advantages of aerated concrete is the ease of its processing, since aerated concrete is a porous material, relatively soft and does not require such titanic efforts as are needed when working with reinforced concrete. When building or repairing a house with the use of aerated concrete blocks, there always arises the need for a device in the walls of various recesses and channels for laying water supply, electricity or reinforcement, that is, carrying out shtenirovaniya.

The strictest compliance with security measures, which includes the following rules:

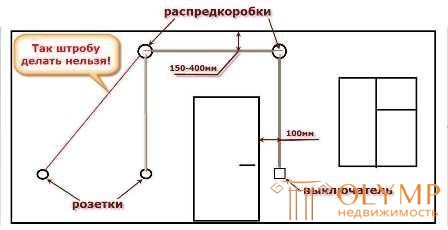

Scheme of correct and improper stubbing of walls

The parameters of the laying of strobe require you to withstand the following parameters:

Preparation for work:

After studying the security measures, the rules of repair or construction, you can sit down at the calculations. It should be borne in mind that you need to buy aerated concrete by 10-15% more than the calculated amount, taking into account its cutting during laying and possible combat. Before making a decision on the purchase of tools, it is necessary to become familiar with the peculiarities of working with aerated concrete.

Shtrobit concrete can be manually and mechanically.

With the help of a manual starborez, you can quite accurately and without raising a large amount of dust make the necessary recesses in the walls of aerated concrete blocks.

For manual work, you can use manual wall chasers, which are of two types. The first - with large figured handles - to work on horizontal surfaces. They are used, as a rule, for laying recesses for reinforcement when laying walls. The second one is longer, with less protruding handles - for working on finished walls. Their purpose - the manufacture of routes for electrical wiring and water pipes. In hardware stores, you can purchase these tools relatively inexpensively.

The advantage of this method is that it is relatively cheap, the groove is made immediately in one pass and does not produce much dust. If you can not stock up with a wall chaser, then the old proven method will help with the use of tools that are in every house - a hammer and chisel. The latter method, although absolutely free, requires tremendous physical effort, a lot of time and does not give the desired quality of work. In addition, the above methods of processing walls are suitable only for minor amounts of repair or construction. When large-scale work should acquire power tools and work with them.

It is possible to carry out the processing of aerated concrete walls with an electric wall chaser, perforator or grinder.

Electric wall chasers have different power and weight ranges. Based on the capacity varies and price range. Among other things, they can adjust the depth of the cut.

In all electric wall chaser there is an opportunity to adjust the cutting depth.

This tool has two disks, rollers for the smooth movement on the processed surface, two handles and the regulator of depth spent on drink. Heavy, powerful wall chaser perform their task faster and easier, but at the same time they are more expensive and take a lot of power, especially when working at the upper levels. Smaller power is good for processing the upper levels of the premises, but at the same time it is necessary to press the device harder, which is also not entirely convenient. If there is an opportunity, then it is worth buying a device with a smooth adjustment of the speed of rotation of the disks, this will avoid dangerous and painful jerks when they start up and will facilitate the work process.

After the cutting is performed, its further processing is carried out, that is, the excavation of the internal contents between the walls of the cutting. This is best done with a chisel or spoon type punch. If you don’t have a punch in hand, then this procedure is carried out with a hammer and chisel, which is very laborious and time consuming. The advantage of an electric wall chaser is that it simultaneously makes two cuts to a predetermined depth quickly and smoothly, without creating much noise and dust. The only downside is its cost. In addition, after the end of construction, it will be absolutely not needed because of its narrow and unique purpose - shtrobit.

The essence of the processing of aerated concrete grinder is the same as that of an electric wall chaser. But unlike the wall chaser, the grinder needs to go through the marking twice to make two parallel cuts. At the same time, it is necessary to constantly control the direction of movement and depth of processing. If you have a good diamond disc, it will not take much time and effort. Subsequent processing of the kerf is absolutely similar to how it is carried out after the walling with an electric wall chaser. К недостатку такого способа можно отнести недостаточную точность пропила поверхностей и невероятное количество пыли, так что придется запастись несколькими запасными респираторами. Бытовой пылесос в таких случаях не поможет, так как забьется и сломается уже через несколько минут, а покупка или аренда промышленного пылесоса – дело экономически невыгодное.

Штробить газобетон с помощью перфоратора можно двумя способами. Первый состоит в том, что в стене сверлом большого диаметра по линии разметки на расстоянии до 10 мм друг от друга сверлятся отверстия на всю длину штроба. Затем с помощью перфоратора с соответствующими насадками типа «зубило» или «ложка» они соединяются между собой. Преимуществом такого способа является то, что он не требует закупки или аренды дополнительного дорогостоящего оборудования. Кроме того, количество пыли, образующееся в процессе сверления, не идет ни в какое сравнение со штроборезом, а тем более с болгаркой. Обратной стороной медали является неточность и неаккуратность обработки поверхности, большое количество затраченного времени и сил, а также невероятный грохот в процессе деятельности.

Если в хозяйстве есть надежный и тяжелый перфоратор, то штробить канавки в стенах можно и без предварительного просверливания широких отверстий с последующим их соединением. Для этого в первую очередь потребуется твердая рука и изрядный запас физической выносливости. Суть этого метода состоит в том, что перфоратор с коротким сверлом большого диаметра под углом 30-45 градусов прислоняется к стене по намеченной линии и включается в режиме сверления. Далее с легким нажимом проводится стачивание головкой сверла материала стены на необходимую глубину. При этом двигаться нужно спиной вперед, ведя сверлом по линии резки. Для удобства работы на сверло можно маркером под углом нанести линию глубины изготавливаемой канавки. Таким способом штрабить можно только газобетон, поскольку он – материал пористый и податливый. Но и в этом случае необходимо соблюдать осторожность, чтобы не испортить перфоратор. Излишнее давление может повредить вал инструмента.

Currently, building materials stores can offer a choice of the most diverse product for every taste and wallet. What to use in the process of repair or construction, it is necessary to decide in each case separately. To make the right decision, you can consult the vendors or, for example, go to the nearest construction site and see how the workers work and ask their opinion about the materials and tools. Such a consultation will greatly help in making a decision and will give some ideas about the order and methods of repair.

Что бы оставить комментарий войдите

Комментарии (0)