Preparation and application of the solution.

The cleanliness of the finished surface largely depends on the quality of the prepared coating solution. A good solution is easily, quickly and cleanly overwritten or smoothed out, which increases the productivity of plasterers.

Fine-grained sand is used to prepare a covering solution. Coarse sand is unsuitable, as it gives a rough rough texture. The homogeneity of the solution plays a large role in the process of its application, and in the grout. If in some places the coating solution is fatter or vice versa, the grout will have a different purity. Therefore, prepared or ready-made solutions are sieved through a sieve before being applied and mixed again. Cover the coat with a solution of the same composition as the previously applied layers of plaster. Fat solutions give a rougher surface, with a large number of nataskov and unwiped strips. These solutions are more suitable for smoothing. Lean solutions are not strong enough and poorly rubbed.

12-20 minutes before applying the coating, the surface of the applied solution is moistened with water. With a moistened primer, the covering adheres more firmly, due to which solidity of the plastering layer is achieved.

The solution is applied to the surface of walls and ceilings in thin layers and leveled with screeds. Coating can also be applied with a falcon smearing.

The cleaner and more carefully leveled solution, the easier it will be to overwrite.

To avoid puttying and make staining directly on the plaster, apply a free-of-charge nakryvku. It is made from lime dough and gypsum. The calcareous dough is taken with a standard cone 12 cm slump. The plaster and lime dough is passed through a sieve with openings of not more than 1X1 mm. Preparing a new portion of the nakryvki, lime paste is well mixed, so that it was of uniform density.

The solution is prepared in small portions without delay retarders gypsum. Lightly grasped or otminolozhenny solution is not used.

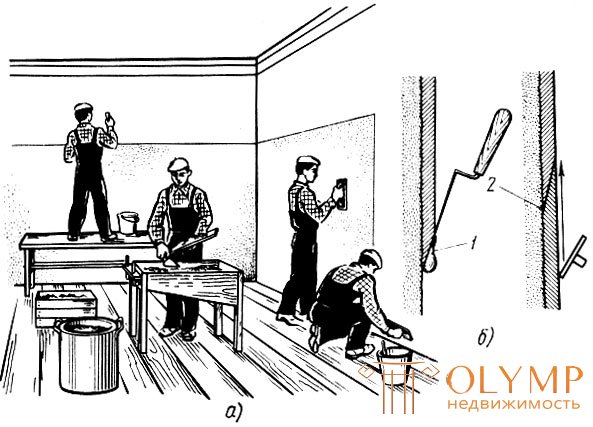

Soil before applying nakryvki align and moisten with water. The solution is applied (fig. 28, a) with a layer of 2–3 mm, smoothed over and smoothed with metal trowels. When joining the nipple (Fig. 28, b), the edge of the previously applied solution is cut off with a cut at an angle of 30 ° and a new portion of the solution is applied to the cut part.

Fig. 28. Application and processing of a sandless coating: a - organization of the workplace, b - joining of sections of the coating; 1 - solution, 2 - joint

Grout . Grouting is performed by gratings and rounding up. Grouting gives a cleaner surface, it is most often done with high-quality plaster.

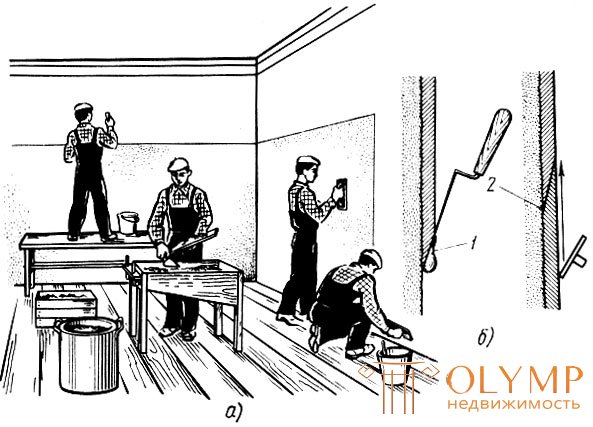

Grouting round (Fig. 29, a) is performed as follows. With one hand, take a grater, press the canvas to the surface of the plaster and make circular movements counterclockwise. Hillocks and irregularities cut off the grater ribs. The solution moved over the surface fills individual cavities and rubs the cap. Pressing the grater should be 1c with different strength: where the surface has a bulge, it is stronger, where the concavity is weaker.

In the process of grouting on the edges of the float cut solution is typed. Periodically, it is cleaned and used for lubrication of protyrin and shells.

Over time, the cover dries out and is hardly rubbed off. To make it softer, rubbed over the surface of the plaster moistened with water with a brush-brush.

When grouting the plaster round the surface, slightly noticeable circular traces remain without shells and the draining of the mortar. Therefore, with high-quality finishes, rounding off the grout is complemented with a grout.

The grouting (Fig. 29, b) is performed as follows. Grater, well cleaned from the solution, tightly pressed to the surface and begin to produce its rectilinear motion - waving. Thus eliminate all traces of grout around.

Grouting is best performed following round grouting. Having wiped a small surface (0.5-1 m) around, it is immediately overwritten by races. If the surface of the plaster, rubbed round, has dried, then it is moistened with water, and then overwritten.

The highest purity of wiped plaster is achieved when the work is done first with a wooden float and then with a float, the cloth of which is upholstered with felt and felt.

The quality of the rubbed surfaces must meet the following requirements. When grouting round circular float left traces should be of the same size without any harnesses of mortar, non-rubbed places, gaps, shells, proterin, tubercles.

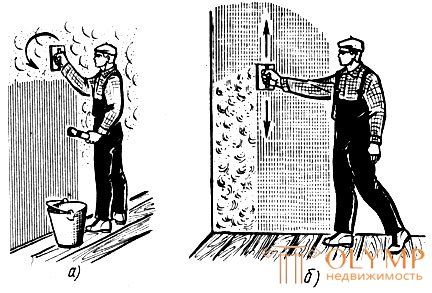

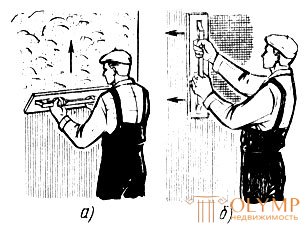

Smoothing The process of smoothing the covering with smoothing brushes differs little from the work of the scraper when leveling the solution. Smoothing is performed in two ways.

In the first case, the applied coating is first leveled with a wooden scraper, and then smoothed over with a trowel in one or two directions. The force of pressure on the trowel is adjusted so that after its passage through the covering there are no traces left. On the walls, the covering is first smoothed in the vertical direction (from the floor to the ceiling (Fig. 30a), and then horizontally (along the length or width of the floor) (Fig. 30b). On the ceiling, firstly smoothing is performed across the rays of light from the windows, and then in their direction.

In the second case, they simultaneously smear and level the coating solution, and then smooth it down.

Fig. 30, Smoothing of the plaster with ironing boards: a - in the vertical direction, b - in the horizontal direction

When smoothing down the work is best done together. One puts the solution and smoothes it, the other smooths.

When smoothing down with a rubber trowel, the surfaces have the appearance of fine sandy textures. It is better to paint such surface with glue paints. When smoothing with metal trowels, the surface of the plaster becomes ironic. It is better to paint with oil paints.

Since the sandless coating is applied in a thin layer, there should be no shells, holes or other defects on its surface. Qualitatively worn nakryvka has a fine-grained smooth texture that does not require shpatlevaniya with a simple color. This increases the productivity of painters, reduces the cost of finishing work.

Что бы оставить комментарий войдите

Комментарии (0)