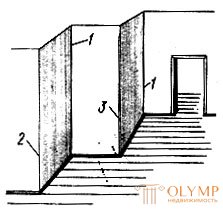

Husk (fig. 31) - an internal corner in places of an adjunction of two walls or a ceiling and a wall; Usenok - the outer corner formed in the places of pairing of two walls. Due to the fact that sharp corners (ussenki) quickly break off, they dull, rounding or removing chamfers. Chamfers are rounded and flat. Well-made husks, usenka or chamfers adorn plastered rooms.

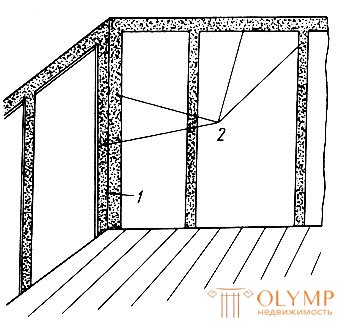

Fig. 31. Wall with husks (1), whiskers (2) and chamfers (3)

Rubbing and cutting husks, whiskers and chamfers are labor-intensive operations. Husks, Usenka and chamfers are performed by scrappers, rule, pattern.

For polishing husks or whiskers use solutions prepared on fine sifted sand. A scraper or rule is applied to the applied solution and, moving it with slight pressure up and down, is rubbed until an accurate clean line of the husk or the little shell is obtained. These elements must be made vertically or horizontally.

Defects are corrected by small trowels with an additional application of the solution in the right places.

Chamfer rubbed on a previously made whiskers. For this, ready-made Usenka are moistened with water, from the end they put a scraper to them and, moving it with a slight pressure up and down, grind the scoop in the same plane or round it off. If the chamfer is wide, then it is possible to pre-cut a part of the solution with a cutter, cut off the cut, moisten the cut face with water and then rub it with a scraper. Chamfer should be completely straight. The flat chamfer should have the same width along the entire length. If the chamfer is rounded, it should be the same profile along the entire length. Correct chamfer small taterkom.

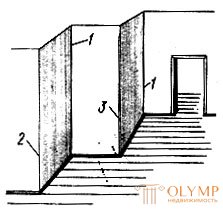

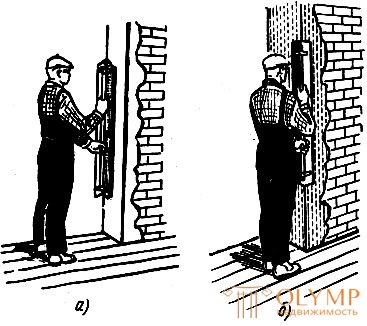

For rubbing husks, whiskers and chamfers, they also use shaped treads (Fig. 32, a, b), the canvas of which is shot down from two planks fastened at a right angle; plasterers also use simple patterns and pullets (Fig. 33, a-b).

Fig. 32. Natirka husks (a) and mustaches (b) shaped pavers

Fig. 33. Devices for extrusion of husks, whiskers and chamfers: a - simple pulp 1 and rules 2, b - a pattern in the form of a trowel, in - a hinged pattern and rules 2

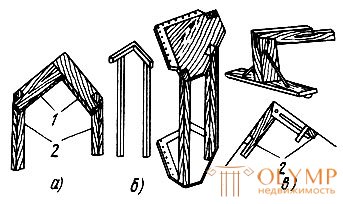

Husks and Usenka also pull on two rules. Since hanging the rules takes a lot of time, they use templates from two profile boards fastened together, which move along a lighthouse frame made of two corners fastened at an angle. In this case, not individual rules are hung, but the whole frame, which increases labor productivity. However, the pattern and lighthouse frame form only a right angle. To obtain an obtuse or acute angle, it is necessary to manually correct one side of the husk, grind, or chamfer, spending additional time. Hinged template with sliding profile board allows you to pull husks, Usenka and chamfer with different angles without additional refueling. To increase productivity, husks are satisfied as follows (Fig. 34). In the corners they are satisfied with the stamps, putting two rules alternately to them. First set one rule and throw a solution under it, then remove it, put the second rule against another wall and put a solution under it. After removing the rules, lighthouses remain 2 in the corners with even sharp husk 1. This can only be when a plastic solution is applied under the rules and filled with the shell and the space between the rule and the wall without shells. It is possible to execute such husks-beacons according to one rule and with marks on one wall only. In this case, the rule is attached to the stamps so that it retreats from the other wall by the thickness of the plaster.

Fig. 34. The device beacons (2) in the corners for the formation of husk (1)

In the future, husks in the corners can be used as beacons for leveling the solution. When leveling the solution, these husks-beacons can be spoiled by the rule; to avoid this, they can be made wider, 60-100 mm in each direction. When such beacons are arranged near the ceiling, their width can be 30-50 mm, since the solution is not leveled.

Что бы оставить комментарий войдите

Комментарии (0)