Violation of technical rules and regulations in the production of plastering works and the preparation of solutions leads to the appearance of defects in plaster: ducats, cracks, peel.

Dutik - a small bump on the surface of the plaster; easily crumbling, leaving a white or yellowish spot in the center.

Dutiki are formed because the solution was prepared on uncured lime, in which small particles were not extinguished. Once in the plaster, they begin to quench after some time and increase in volume. Cancellation can last for quite a long time, sometimes for years. In order to avoid dutik, freshly poured or poorly maintained lime dough used to prepare the mortar must be filtered through a sieve with openings of 0.6 x 0.6 or 0.5 x 0.5 mm.

Cracks large and small appear on the surfaces of the plaster because they use either greasy (with a high content of binders) or poorly mixed solutions, in which many binding materials or aggregates accumulate in places. Cracks can also occur as a result of the application of otmenolozhennyh lime-gypsum solutions or from the rapid drying of the applied plaster under the influence of strong drafts or high temperature. Cracks are also formed from the deposition of a thick layer of a slowly setting solution at one time or because the solution is applied, although in thin layers, but on the previous layer of the solution that has not yet set.

To avoid the appearance of cracks, it is necessary to strictly dose the binders and aggregates when preparing the solution and mix it thoroughly. In a freshly prepared solution, you can add no more than 10% of the frozen solution. The applied plaster must be protected from extremely rapid drying, drafts, closing the windows and doors in the plastered premises. In hot or windy weather, it is recommended to veil the plaster on the facades with wet matting or pour water frequently.

Cracks, definitely directed, are formed on wooden or brick surfaces: on wooden - in the cells of stuffed drains, on brick - in the seams of the masonry. On wooden surfaces, this occurs because a thin layer of mortar is applied on them or a very wide tear is filled, which warps under the layer of plaster and breaks it. In order to prevent cracks from occurring, apply a hole no wider than 2 cm. The thickness of the plaster layer on wooden surfaces must be at least 15 mm, counting from the level of the output drift. Cracks on brick walls appear as a result of applying very thin layers of plaster without first wetting the surfaces with water. The cause of the formation of cracks can be alkali, released from the joints of the masonry.

Pitting and exfoliation of the plaster occurs when plastering wet surfaces or when the plastered surfaces are constantly wetted. Most often this happens on lime and lime-gypsum plasters. In order to avoid pitting and bloating of plaster, damp places need to be dried and only then plaster.

Peeling of plaster is caused by the fact that the solution was applied on an excessively dry surface or on the dried layers of a previously applied solution. Exfoliation can also occur as a result of the fact that the subsequent layers of mortar were applied on weaker previous ones, for example, a more durable cement mortar was applied on the mortar. The plaster is also peeled off if a lime or lime-gypsum mortar without transition layers is applied to the concrete base or cement plaster. To avoid exfoliation, it is necessary to apply the concrete onto the concrete surfaces first with a cement spray, then with a complex, i.e. lime-cement mortar, and then plaster with a lime mortar.

Colored and decorative covering layers exfoliate when they are applied to very strong or, on the contrary, very weak soils, when the covering layer is much stronger and denser than the soil itself or they cover soils with an insufficiently rough surface.

Cracks in the husks appear as a result of the fact that the corners of the walls or the joints of dissimilar surfaces made of different materials were not sufficiently prepared or because the solution was applied to dried wooden surfaces. Cracks appear in the event that plastered structures were fixed fragile.

Before plastering, the corners and joints of dissimilar surfaces should be covered with mesh strips, and dry wooden walls, partitions, and ceilings should be well moistened with water.

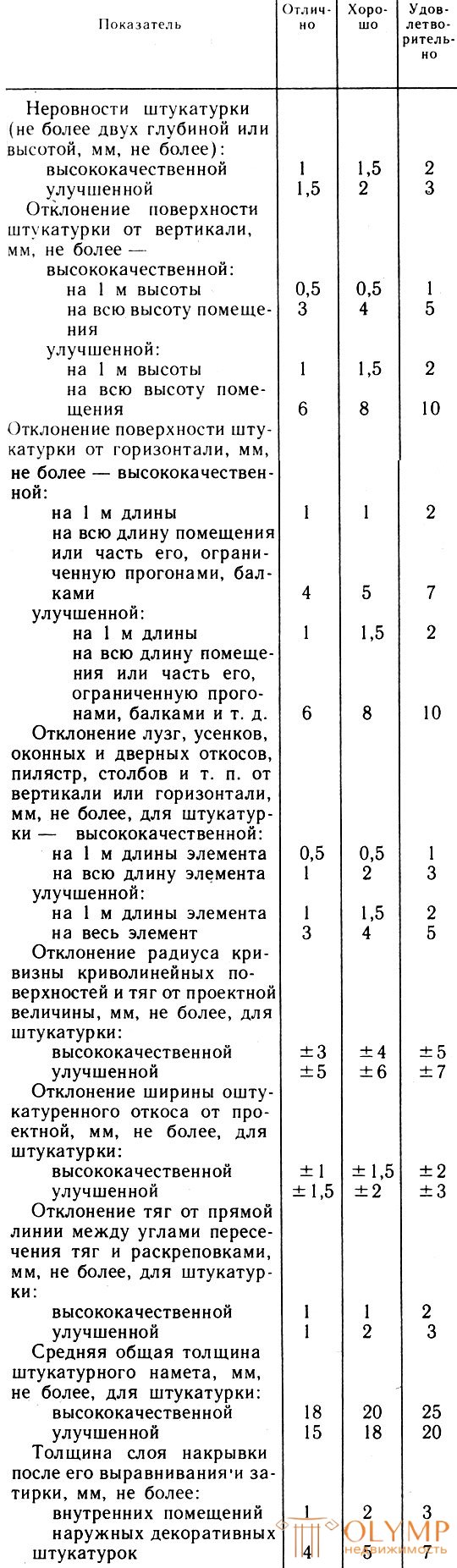

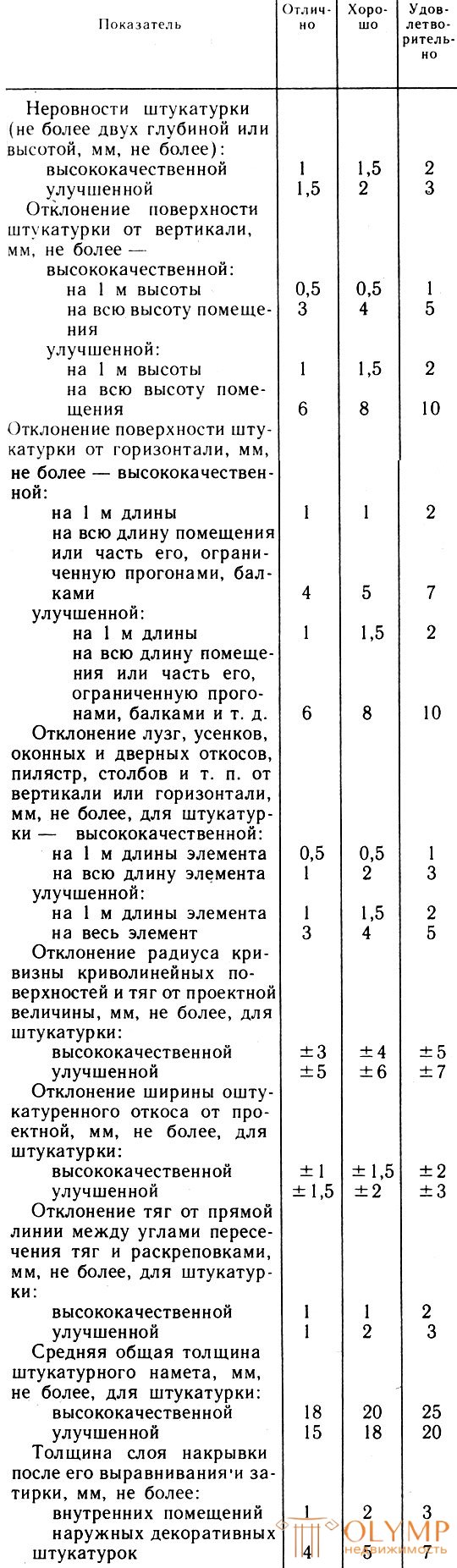

Within the limits of tolerances set by the SNiP, plaster can be done better or worse. The quality of work is determined by the indicators table. 3

Table 3. Evaluation of the quality of plaster

Что бы оставить комментарий войдите

Комментарии (0)