There are many methods of manufacturing prestressed concrete, but all of them can be classified according to their concept as tension on the stops and on tension on the concrete.

Structures in which the reinforcement is tensioned until the concrete hardens are called "constructions with tension of the reinforcement on the stops or on the form."

When tensioning reinforcement after hardening of concrete, structures are called “structures with tensioning reinforcement on concrete.”

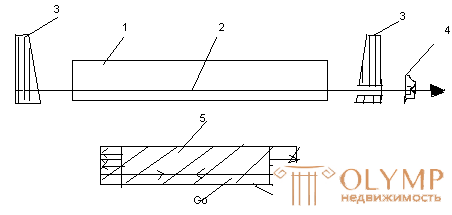

A) 1. The tension on the stops.

1-form

2-armature

3-stop

4-jack

5 hardened concrete

The manufacture of elements with tension on the stops is as follows. The armature is placed in the form before concreting the element. One end of it is fixed in the support, and the other in a tensioning device (jack). After tensioning the reinforcement to the specified stresses (within the elastic deformations), fix its second end. Then the element is concreted. When the concrete gains the necessary strength (Ro> 0,7R), the reinforcement is released from the stops. In an effort to regain its original length, the reinforcement compresses the concrete surrounding it, due to its adhesion. In this case, the valve loses some of the prestressing. If a reinforcement that was not subjected to prestressing was laid in the structure, then it also receives compressive stresses when the concrete is compressed.

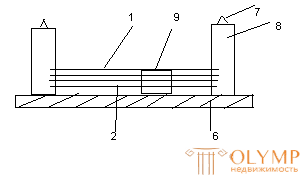

Laying reinforcement in the form and its tension combined in a single operation. We have a pallet equipped with pins located in the respective design position of the valve.

6) pallet; 7) pallet pins;

8) tubes; 9) clamp;

On the pins wear steel tubes. A special coiling machine wire armature wound on the tube with a given amount of stress, and its end is fixed with a plastic clip. The pins of the pallet wire is held taut. When the concrete gains sufficient strength, the product is removed from the pallet, and the reinforcement compresses the concrete. The tubes remain in the concrete body and play the role of anchors.

The tension of the reinforcement can also be created by electrothermal method .

Harvested rods are heated by electric current to t = 300-400 degrees, due to the fact that they are extended. The heated rods are placed in the form, and their ends are fixed on the stops located on the form, or outside it. When cooling down, the reinforcement tends to restore its original length, but since it is held by stops, tensile stresses arise in it. After concreting and hardening of concrete, the reinforcement is released from the stops and the concrete is compressed.

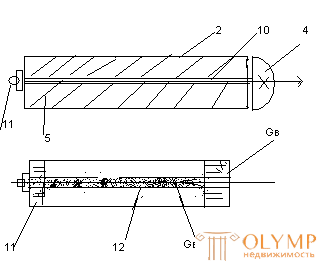

B) Tension on concrete.

When the concrete is tensioned, they first produce a concrete or little reinforced element; then, when concrete reaches a strength of at least 0.7 R, a prestress is created.

Strained reinforcement is located in the channels and under tension does not adhere to concrete. The compression of concrete occurs in the process of tension reinforcement. The stress in the concrete is controlled after the concrete is compressed. The element channels have a diameter of 5-15 mm larger than the diameter of the reinforcement and are made during the concreting of the element by laying corrugated steel tubes (shells) or hollow cores extracted from concrete. The valve is passed through the channel. One end of it, provided with a corresponding anchor, is fixed at the end of the element, and the other is jacked onto the opposite end. The jack, resting against the end of the concrete element, produces the tension of the reinforcement and simultaneously compresses the concrete. After tensioning the reinforcement to a predetermined voltage, it is anchored from the side of the location of the jack. The tension of the reinforcement can be made from 2 sides.

To increase the strength of concrete for local compression at the ends of the element establish transverse grids. Adhesion of reinforcement to concrete is created as a result of subsequent filling of the channel with cement paste or mortar that is forced under pressure through holes in the end anchors or through special taps located along the channel length through 6m. This channel filling is called injection.

In recent years, to create a pre-tension in the structures they begin to use reinforced concrete prepared on special pre-stressed cements. Concretes on such cement during hardening increase in volume, and as a result of adhesion with reinforcement they stretch it. Since the reinforcement prevents free expansion of concrete, compressive stresses occur in it.

The armature can be positioned in the element in two or even three directions, then a corresponding biaxial or triaxial prestress is created.

MATERIALS.

As prestressing reinforcement steel is used predominantly At-VI; А-V long up to 12 m, steel of classes А-Vl, AV, A-IV is allowed, and with longer length steel of classes B-II, Bp-II, K-7, K-19. For constructions operating in corrosive environments, reinforcement classes A-IV, thermally reinforced reinforcement of all classes (except At-IVc) and high-strength wire are used. It is forbidden to weld or weld embedded parts to it.

The profitability of stressed reinforcement increases as its strength increases, since the amount of reinforcement required by calculation decreases in proportion to the increase in its design resistance.

(strength); for example, in stretched elements: As = N / Rs, the more Rs, the less reinforcement is required, and the cost increases slightly. The unit cost of reinforcement “K” is the ratio of its price “C” to the calculated resistance of reinforcement Rs.

K = D / Rs - this shows that with increasing strength of reinforcement

(with an increase in Rs), its unit cost decreases and, consequently, its effectiveness increases.

Reinforcing ropes and bundles.

Reinforcing structures with individual high-strength wires, due to their large number, is laborious and often leads to excessive section of elements. In this regard, the wire is enlarged into ropes or bundles. Ropes are usually made of 7 or 19 wires of the same diameter (designation K-7 or K-19), winding the rest in one or several layers onto the central straight wire. The diameter of the wire ropes K-7 from 2 ... .5 mm. Spiral-twisted multi-strand ropes are used in heavily loaded structural elements: two-strand class K2x7, three-strand class K3-m, multi-strand Kn * m, where:

"M" - the number of wires in the strands.

"N" is the number of strands in the rope.

The bundles consist of parallel high-strength wires (14,18,24) or ropes. Bundles can have anchors at the ends, and are wound with a soft wire along the length.

Concrete for prestressing structures used conventional or high grade.

Coupling of reinforcement stresses with concrete. Self-embossing rebar. Anchoring devices.

In prestressed structures, reliable adhesion of prestressed reinforcement to concrete must be ensured. If at any stage of the manufacture of the prestress of the structure reliable adhesion cannot be ensured, anchors must be installed at the ends of the prestressed reinforcement. So, for example, in constructions with tension on concrete, installation of anchors is obligatory in all cases, as prestressed reinforcement located in channels does not adhere to concrete until it hardens the solution injected into channels or filling grooves. In constructions with tension on the stops with prestressing reinforcement of a periodic profile, self-anchoring of the reinforcement takes place, which ensures reliable adhesion of the reinforcement to the concrete without the use of anchors.

Strained reinforcement from smooth high-strength wire should always be provided with an anchor.

Types of anchors are various:

These can be tubes, put on pins and remaining in the body of concrete. Rod fittings are anchored using short, welded washers, nuts.

Что бы оставить комментарий войдите

Комментарии (0)