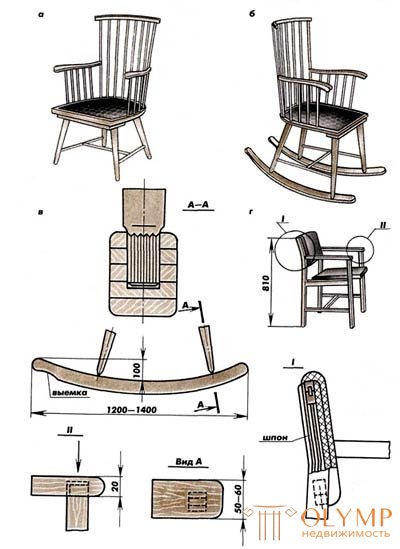

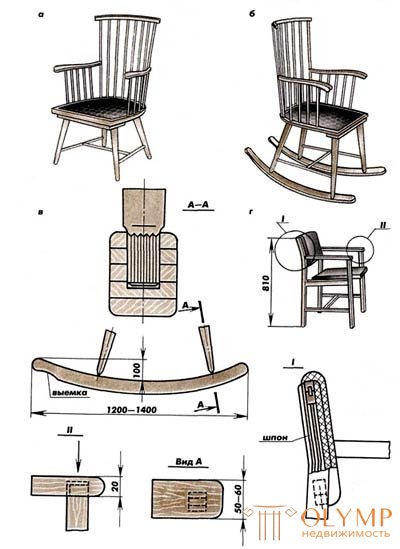

Joinery chairs and rocking chairs are made with a decoy and solid rear legs. The constructive solution of working chairs (Fig. A) and rocking chairs (Fig. B) with stooping legs is basically the same as chairs.

Joinery chairs and rocking chairs are made with a decoy and solid rear legs. The constructive solution of working chairs (Fig. A) and rocking chairs (Fig. B) with stooping legs is basically the same as chairs.

Seats make the frame structure of bars with a thickness of 30-35 mm, which provides a solid attachment to the seat of the details of the armrests with screws or bolts with a semicircular head.

Curvilinear rocking chairs (Fig. C) are bent from planks of solid wood with a thickness of 10 mm. The cross section of the runners after processing 50x40 mm. Runners behind have dredging which suppresses swing speed and, therefore, warns overturning of a rocking chair during normal operation. The legs of the rocking chair are connected to the runners on a solid round thorn with a diameter of at least 20 mm.

The distance between the armrests in work chairs and rocking chairs should be at least 420 mm, the width of the seat in the widest part of at least 400 mm. The distance from the seat to the upper plane of the armrest is 180-240 mm.

The working chair shown in the figure (fig. D) and the rocking-chair with stooping legs are unified. Under the unification of the design of furniture products refers to the reduction of parts included in the product to a single form, design and size. Products with the maximum possible number of standardized parts are more technological compared to products that do not have component unification or it is insufficient.

The desire to unify as much as possible the details that make up the products created a trend in furniture design on the principle of interdisciplinary unification.

Interdisciplinary unification involves the use of unified parts not only in one product, but also in several products of the same type, different or identical in function. A group of similar furniture items, such as dining tables, assembled from a limited number of standardized parts, is called a technological product series.

Technological series design products with common design and technological features: bar, cabinet furniture, etc. For example, based on standardized parts bar furniture can be created that are different in function (armchairs and rocking chairs) or of the same functionality. (chairs with different backs).

The manufacture of furniture by technological series in the conditions of home workshops and individual labor activity makes it possible, on the basis of unified parts, to organize the manufacture of products of various shapes and functions with lower labor costs.

An example of the unification of the working chair and stool with stooping legs is shown in Figure a. The design of the working chair differs from the design of the chair only in the presence of armrests and parts for their attachment. The technological series consists of two products of different functional purpose.

A joinery work chair with solid rear legs, economical in terms of wood consumption, is shown in the figure of G. The legs of the worker’s chair are made of bars of the same cross section. The rear legs of the workbench chair are slanted with longitudinal cuts at the ends of the legs. Bend the end of the leg can be in wooden templates clamps. The seat and backrest of the worker's overhead, fastened to the dowels and screws.

Что бы оставить комментарий войдите

Комментарии (0)