Forests are stationary and mobile. Of the stationary most common tubular metal scaffolding.

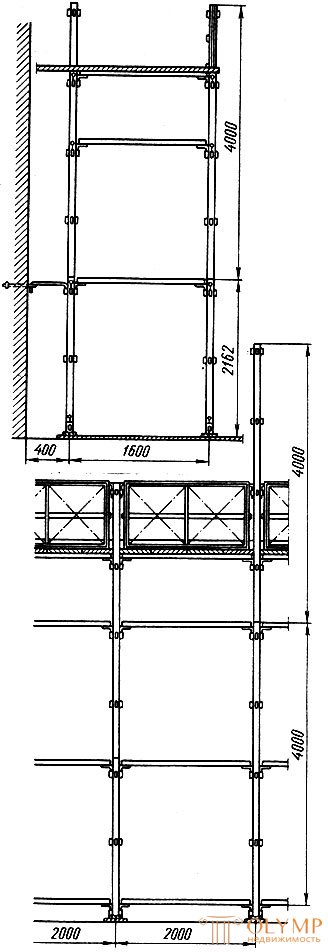

The tubular scaffolding of the Promstroyproekt construction (Fig. 2) consists of racks and girders connected by hooks and nozzles without bolts. The maximum height of scaffolding for finishing work is 60 m. The width of the working floor is 2000 mm. The stands of the scaffolding are 400 mm from the wall. For decorative trimming, this distance is increased to 600-700 mm. The distance between the posts in the transverse direction is 1600 mm, in the longitudinal direction - 2000 mm. The flooring is made of wooden boards.

Fig. 2. Tubular scaffolding of Promstroyproekt

For climbing and descending from the scaffolding in the middle of them, staircases are arranged every 40-50 m. At the locations of the stairs, floorings are arranged with small fences in all even tiers.

Scaffolding attached to the walls with hooks. One side of the hook hook on the eye of the anchor-bolt, the other - for the rack.

Along the outer row of racks, on the inside of the flooring, side boards are installed so that tools and materials do not fall from the floorings.

If you have to deliver the material on the scaffolding wheelbarrows, then arrange rolling boards.

Over passages and passages arrange protective canopies; canopies cannot be used for workers and storage of any goods and materials.

Every day, before starting work, it is necessary to check the condition of the scaffolding: monitor the strength of their attachment, the quality of the flooring, the health of the lightning ground and grounding.

Tubular scaffoldings of the TsNIIOMTP construction are universal, for finishing works they are mounted to a height of 60 m with tiers of 2 m each. The details of the scaffolding are interconnected with clamps. Racks set from the walls at a distance of 400 mm. The distance between the uprights in the transverse direction is 1400 mm, the total width of the scaffolding is 1800 mm. Scaffolding is attached to the walls with inventory anchors and traffic jams. Corks are plugged or laid in holes punched in the walls, and screws are screwed into corks. Inventory plugs with a conical tip on the working rod are also used. It is inserted into a split metal pipe, which is fixed in the sockets arranged in the walls.

Mobile forests and towers are self-propelled or moved by workers. The towers have a small platform in comparison with the forests, but they can be advanced to a height of 15-32 m. During movement, no people or materials should be on the forests and towers.

The base for scaffolding is leveled, sometimes they make massive wooden flooring. Forests in workplaces or parking areas are attached to the walls of the building. Decking on the grounds of forests continuous. On the outer side of the flooring, as in the scaffolding of all other structures, they reinforce the side boards. The working platform is protected with boards or pipes to a height of at least 1 m, counting from the flooring.

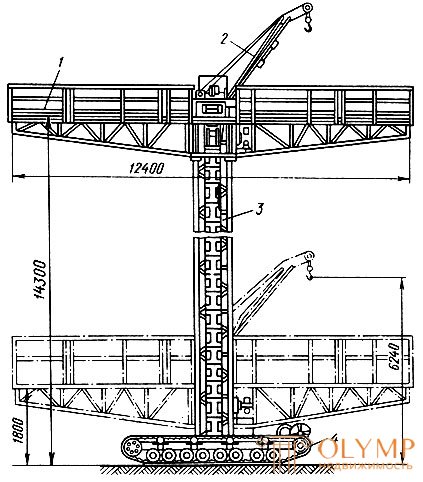

Mobile crawler-mounted scaffoldings (Fig. 3) are used to finish the facades of buildings and structures up to 15 m high. The length of the working platform 1 along the work front is 12.4 m. The carrying capacity of the platform is 2000 kg. The working platform rises or falls at a speed of 1.4 m / min. Scaffolding moves at a speed of 10 m / min.

Fig. 3. Mobile tracked scaffolding: 1 - working platform, 2 - crane, 3 - tower, 4 - movement mechanism

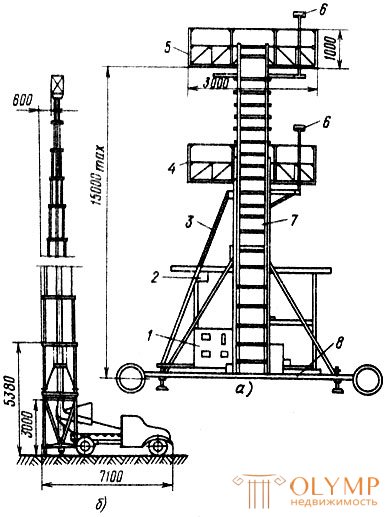

The telescopic pneumatic-mounted tower , moved by workers (Fig. 4, a), has two platforms - the top 5 and the average 4. The length of the platform is 3 m with fences up to 1 m high.

The autotower (fig. 4, b) has a single platform. It is mounted on a car and can move not only within one object, but also from one object to another.

Fig. 4. Mobile towers: a - telescopic pneumatic wheel, b - aerial platform; 1 - electrical equipment, 2 - winch, 3 - jack, 4, 5 - platforms, 6 - crane, 7 - telescopic column, 8 - trolley

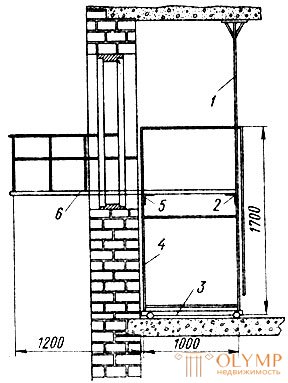

The collapsible platform (Fig. 5) is intended for plastering external slopes, finning and covering gaps between the box and the wall, for painting the bindings on the outside. It is made of steel pipes - 4 frame racks. The skeleton of the platform is mounted on a metal frame 3 mounted on rolling supports. To the frame at the corners 2 and 5 is fixed portable platform 6 with a fence. Removal of the site depends on the thickness of the walls of the building. With a wall thickness of 2.5 bricks, the length of the platform should be no more than 1,400 mm.

Fig. 5. Collapsible inventory area: 1 - retractable tube, 2, 5 - corners, 3 - metal frame, 4 - frame stand, 6 - portable ploshadka

To install the site into position, it is brought into the window opening. Retractable tubes 1 with metal plates 150 x 150 mm welded at the ends abut the overlap, which prevents the site from tilting towards the street.

Что бы оставить комментарий войдите

Комментарии (0)