Construction processes called production processes occurring at the construction site and having the ultimate goal of the construction, reconstruction, restoration, repair, disassembly, relocation of buildings or structures. Objects and tools of labor are involved in any construction process. With the help of tools, workers work on the object of labor; For this purpose, various mechanized tools and construction machines are used. In many construction processes, workers use assistive devices and fixtures, such as scaffolding and scaffolding, elevators, hanging ladders, etc.

A simple process is a set of technologically related work operations performed by the same worker or by the same group (link) of coordinatedly acting workers, for example, when laying brick walls.

A complex process is a set of simultaneously carried out simple processes that are interconnected in direct organizational and technological dependence, which provide the final product, such as installation of prefabricated building structures.

Mechanized construction processes are called, in which the machines are used. At the same time, the workers start, control and stop the machines, as well as take care of them, and constantly monitor the operation of the machines.

Complex-mechanized processes are called (mainly complex), in which all technological processes included in their composition are fully mechanized.

Automated processes are those in which automation tools are used.

Automatic processes are those that are fully controlled, regulated and controlled by automata.

Construction works consist of construction processes (simple, complex, and their combinations), the result of which is a certain construction product. It must meet the requirements of the project and the relevant technical conditions for its size, shape, surface structure, position in space and quality.

Certain types of construction work received their name or by type of processed materials, or by structural elements, which are products of this type of work. On the first sign distinguish earth, stone, concrete and other work; on the second - roofing, insulating, etc.

Production processes and production in construction.

The technology of building production , in turn, is the combination of two subsystems: the technology of building processes and the technology of building buildings and structures.

Building process technology determines the theoretical foundations, methods and methods for performing construction processes that ensure the processing of construction materials, semi-finished products and structures with a qualitative change in their state, physicomechanical properties, and geometric dimensions in order to obtain products of a given quality. At the same time, the concept of “method” includes the principles of building processes based on various methods of influence (physical, chemical, etc.) on the subject of labor (construction materials, semi-finished products, structures, etc.) using tools (construction machines, tools small-scale mechanization, mounting accessories, various devices, equipment, devices, manual and mechanized tools, etc.).

The technology of construction of buildings and structures determines the theoretical foundations and regulations for the practical implementation of the implementation of certain types of construction, installation and special works, their interconnection in space and time in order to obtain products in the form of buildings and structures.

Construction production in our country mainly develops on an industrial basis - the direction of turning construction into a fully mechanized process of assembling buildings and structures from standardized factory-made elements.

Currently, domestic builders continue to develop the main ways to improve capital construction, improve the efficiency of capital investments. To this end, the focus is on ensuring the timely commissioning of fixed assets and production capacity, concentrating funds and resources at major construction sites, directing capital investments primarily to retool and reconstruct existing enterprises and to complete construction projects that have been started earlier, shorten construction times, improve project business, implementation of construction on the most progressive and economical projects.

The implementation of measures to significantly reduce the cost of manual labor, equipping builders with high-performance machines and mechanisms, means of small-scale mechanization, and effective mechanized and manual tools continues. A further increase in the level of industrialization of the construction industry and the degree of prefabrication of building structures and parts is being carried out. Currently, intensive development is gaining monolithic and precast-monolithic housing construction.

The implementation of these measures should ensure a significant increase in labor productivity in construction and be determined, inter alia, by improving the safety of workers, solving environmental problems and protecting the environment.

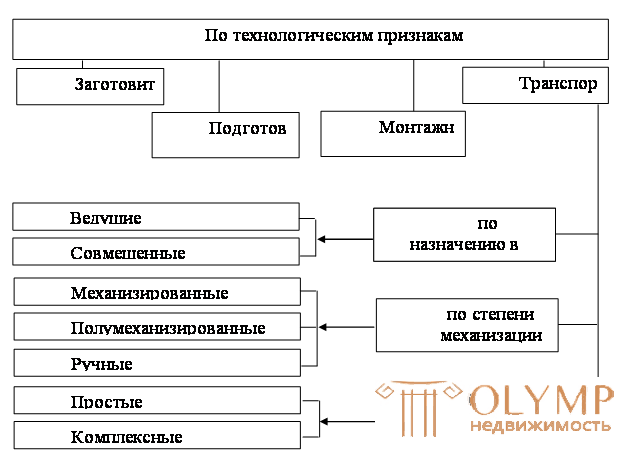

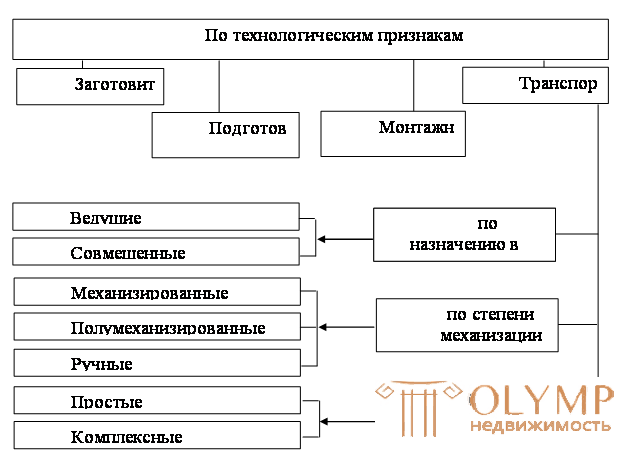

Construction processes (Fig. 11.1.) .

Fig. 11.1. - Classification process diagram

construction production.

Productive human activity is characterized by a sequence of actions aimed at achieving the goal. For the expression of such activities use the term "process". The validity of the use of such a term is explained by its original meaning - “passage”, “promotion”.

Conventionally, processes are usually divided into two groups: material and informational (Fig. 11.2.).

Material processes cover all actions aimed at material objects of production and change their state, which leads to the creation of products.

To information processes includes all actions performed with ideal objects (numbers, information, etc.). The results of information processes are the basis for the implementation of material processes, especially for their design, decision-making, training, management, etc.

The basis of the technology of construction production are material processes, which are called construction processes or building production processes. Workers (labor) participate in building processes, technical means are used (tools), with the help of which building products are created from the material elements (objects of labor).

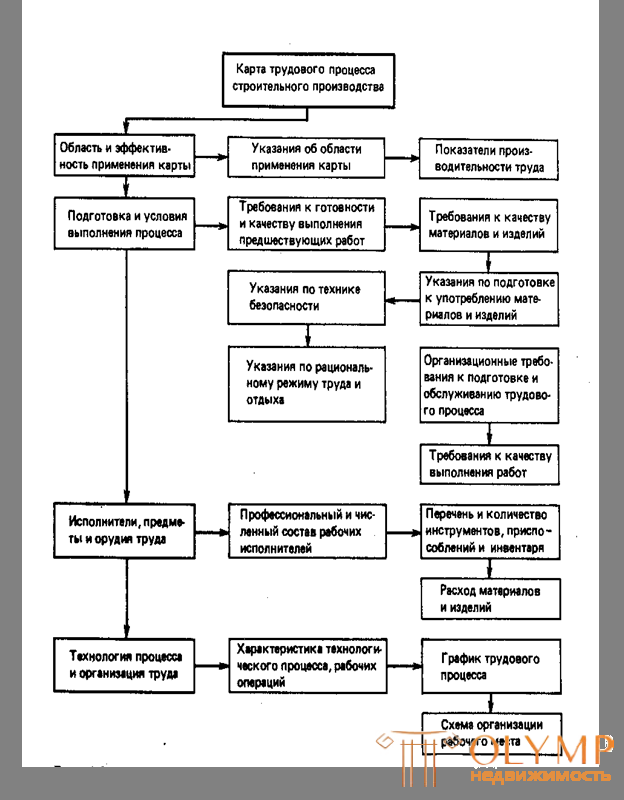

Fig. 11.2. - Composition and structure of building a map of the labor process of building production

Construction processes are characterized by multi-factoriality and specific features, which is caused by:

- stationarity of construction products - when performing construction processes, working and technical means are moved, while buildings and structures being erected remain fixed;

- large-size and mass-capacity of construction products - erected buildings and structures, as a rule, have considerable dimensions and weight;

- a variety of construction products - erected buildings and structures differ in production and operational characteristics, shape, size and appearance, location in relation to the surface of the earth, etc .;

- a variety of material elements - in the construction of buildings and structures are used a variety of materials, semi-finished products, parts and products, with the technological impact on which building products are created:

- climatic conditions - buildings and structures erected in various geological, hydrological and climatic conditions;

- conditions of reconstruction and technical re-equipment of enterprises –construction processes are performed, as a rule, on cramped sites;

- small dispersed volumes, in existing workshops, etc.

These features require, in each specific case, the establishment of technologically correct and efficient methods for the implementation of construction processes, their organizational forms and interconnection in space and time, capable of ensuring the quality and cost-effectiveness of construction products.

In terms of their content, construction processes are a combination of two aspects. The first aspect determines the features that occur with material elements in space and time without changing their physico-mechanical properties, namely: transportation, installation, assembly, docking, etc. The second aspect determines the physicochemical transformations that change the final properties of material elements, namely : strength, density, strength, thermal conductivity, water resistance, etc.

Since many material elements are involved in the construction industry, construction processes are unequal in the degree of technological complexity and cause a variety of structural changes in materials, occur differently in time, with different labor participation of workers, using different technical means.

The effectiveness of the construction industry is largely determined by the organizational provisions and the forms of implementation of all the processes associated with the creation of building products.

In modern industrial construction, construction processes are classified into two groups - off-site processes and processes performed at the construction site.

The basis for the classification of construction processes is their division by technological features into procurement, transport, preparatory, and installation and laying.

In terms of production processes can be leading and combined.

Leading processes determine the development and implementation of construction of the facility.

Combined processes that are not technologically directly related to leading processes can be carried out in parallel with them. The combination of processes (with strict observance of safety rules for workers) can significantly reduce the duration of construction.

Processes are also classified according to the degree of participation of machines and means of mechanization in their execution.

Mechanized processes are performed using machines. The workers here only drive and service the machines.

Semi-mechanized processes are characterized by the fact that they, along with the use of machines, use manual labor.

Manual processes are performed by workers using tools.

Depending on the complexity of production, work processes can be simple and complex.

A simple labor process is a set of technologically related work operations that provide finished products and are performed by a group of coordinatedly working performers of the same specialty, but of different qualifications (link, specialized team). Each work operation consists of work methods, which, in turn, consist of work movements. The labor movement is a single continuous movement of the worker’s executive body (fingers, hands, feet, etc.) carried out by the worker in the labor process, and the working technique is a combination of several continuous movements of the worker, characterized by a specific goal, uniting these movements, their sequence.

A comprehensive workflow is a set of simultaneously carried out work processes that are in mutual organizational and technological dependence and are connected by the unity of the final product. An integrated labor process is usually performed by a group of concertedly working performers of various specialties and different qualifications (an integrated team).

Technological features of some processes necessitate a temporary break in the actions of all or part of the workers employed in the process. In these cases, breaks are technological, in contrast to breaks caused by meteorological causes, and downtime due to poor organization of processes.

Что бы оставить комментарий войдите

Комментарии (0)