A drill is a cutting tool, with a rotating cutting motion and an axial feed movement, designed to drill holes in a continuous layer of material. Drills can also be used for reaming, i.e., increasing existing pre-drilled holes, and drilling, i.e., obtaining non-through holes.

The number and position of the cutting edges, grooves, cutting tools and corners used is called the drill geometry .

According to the design of the working part of the drill are divided into spiral and flat.

According to the design of the tail part of the drill are divided into:

Drills are commonly manufactured using various technologies. Solid twist drills are made from high-speed steel grades P9, P18, R9K15 with a diameter of up to 8 mm, or from a hard alloy with a diameter of up to 6 mm. Spiral drills with a diameter of more than 8 mm are manufactured by welding (the tail part is made of carbon, and the working part is made of high-speed steel). Drills equipped with hard-alloy plates - are with straight, oblique and helical grooves (including with ω = 60 ° for deep drilling). Drills with interchangeable carbide inserts - also called case (the mandrel to which the seams are attached is called the case) are mainly used for drilling holes of 12 mm or more. An alternative to body drills is drill bits with interchangeable carbide heads.

Different types of drills are designed for processing different materials. Based on the characteristics of the material (wood, stone, concrete), drills can vary significantly in design and features.

Consider the types of drills on the example of the company Bosch.

HSS-R Metal Drills

Drills with this marking are intended for alloyed and unalloyed steel with a tensile strength of up to 900 N / mm², non-ferrous metals, gray cast iron, hard plastics. High elasticity is provided by special heat treatment. Minor probability of a break - especially when drilling holes with a diameter of less than 6 mm. The spiral groove with an oxide coating allows you to quickly remove chips. Thanks to the required core thickness and exceptional hardness in the working area, the drill has a long service life.

| Description | |||

| HSS spiral drill bit to DIN 338 | |||

| Right-handed twist drill, type N, tip of drill 118 °, diameter tolerance h 8 | |||

| Rolled helix with ground chamfer, with surface hardening by steam treatment | |||

| The shank corresponds to the drilling diameter, drill color: black | |||

| 2 cutting edges, cyl., 2-alcohol | |||

| Note: when working with HSS-R metal drills, use universal grease. | |||

Metal drill HSS-G

Drills with this marking are intended for alloyed and non-alloyed steel with a tensile strength of up to 900 N / mm², steel casting, gray cast iron, iron-based metal-ceramic alloy, ductile iron, non-ferrous metal, hard plastics. Precisely sharpened HSS-G steel drill bits allow you to drill at a rate 40% higher and with less pressure 50% than a standard HSS drill bit with a tapered sharpening. The self-centering tip of the drill with a cross-shaped point makes it unnecessary to pre-punch or drill holes with a diameter of up to 10 mm.

| Description | |||

HSS spiral drill bit to DIN 338 Right-hand twist drill, type N, tip of a drill 135 °, cross-point point to DIN 1412 C, tolerance for diameter h 8 The diameter of the shank corresponds to the diameter of the drill, drill color: white 2 cutting edges, cyl., 2-alcohol Note: when working with HSS-G metal drills, use universal grease. | |||

HSS-Co Metal Drill

Drills with this marking are intended for alloyed and non-alloyed steel with a tensile strength of up to 1000 N / mm², stainless steel V2A / V4A, gray cast iron, cast steel, acid and heat-resistant steels. Precise drill bits with exceptional thermal and wear resistance. Suitable for use in drill stands or vertical drilling machines.

| Description | |||

· Spiral drill from alloyed high-speed steel to DIN 338, cobalt content 5% · Right-handing twist drill, type N, tip of the drill 135 °, cross-point point to DIN 1412 C, tolerance for diameter h 8 · Fully sharpened twist drill with exceptional surface finish in accordance with a special factory standard · The diameter of the shank corresponds to the diameter of the drill, the color of the drill: bronze · 2 cutting edges, cyl., 2-alcohol · Note: when working with HSS-Co metal drills, use universal grease. |

Step drill bits HSS, straight shank

· For non-ferrous metals, sheet steel, plastics · Without preliminary drilling in the thinnest sheets, without burrs, without cold welding, edge reamer, constant drilling steps · Honed drill bit |

Description | ||

· For hard and soft wood · Drill with centering point and outer cutting edge · Color of a drill: black, polished chamfer · Double helix | ||

Description | ||

· For all breeds of soft and hard wood, even for wet wood · Optimum for finishing construction work, for use by carpenters, roofers · Can be used in all drills with a 13 mm drill chuck · For through holes and pre-drilling of holes for pins and core dowels · Precisely sharpened to comply with the hole sizes. · High drilling speed due to optimized spiral geometry · Hex shank · High margin of safety, fine surface grinding | ||

Description | ||

· For soft and hardwood, as well as lightweight construction materials such as drywall · Precisely ground point and cutting edges for accurate hole sizes · 1/4 "hex shank to ISO 1173 E6.3 · Color of a drill: gray, | ||

The shock-resistant shock drill guarantees increase in service life in concrete and granite, very strong on a bend. The unique spiral shape with a deep U-shaped feed groove reduces dust clogging = increased drilling performance. The carbide tip fixed in width and depth prevents the tip from breaking. Diamond-sharpened carbide cutting edges soldered with high-temperature soldering for fast, accurate and safe drilling.

Description | |||

· For granite, concrete, brickwork, limestone, natural and artificial stone · Shock-resistant, high-performance drills to ISO 5468 for any impact drills · For drilling holes for dowels · Color of a drill: blue, white polished | |||

High-performance universal drill for drilling in almost all materials - there is no need to replace the drill. Innovative deep spiral for fast removal of drilling dust and sawdust. Special universal sharpening - the guarantor of high performance tools. The point is the main cutting edge for precise centering. Core drill of alloyed tool steel for high service life.

Description | |||

· Practically for all materials when finishing indoors, for example concrete, a bricklaying, a brick, eternit, light construction materials, multilayered materials, ceramics and a tile, wood, plastic, sheet metal, aluminum | |||

The optimum drill bit for soft to medium hard tiles. Diamond sharpened carbide cutting edge for extremely precise drilling prevents the drill from moving to the side.

Description | |

§ For any ceramic tile from soft to medium hardness, porcelain, ceramic and non-tinted glass § drill color: white § Note: apply at low revs and in hammerless mode. No cooling required | |

Confirmat drill - purpose and use.

Confirmat (known as evrovint, evroshurup, "" screw screw ").

Confirmata most common in our country, diameter 6.3-7 mm

For the connection of two furniture parts by the confirmator it is necessary to perform three operations.

1. drill a hole for the threaded part with a diameter of 5 mm

2. drill a hole under the non-threaded (smooth) part

3. countersink under the cap

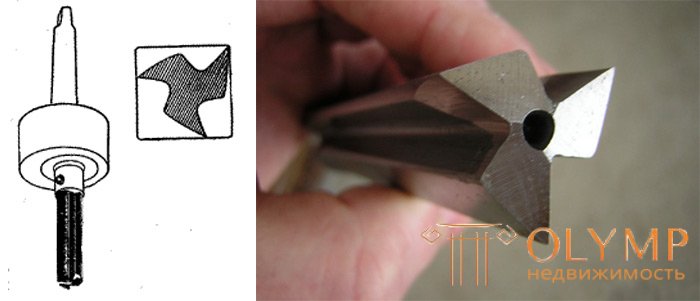

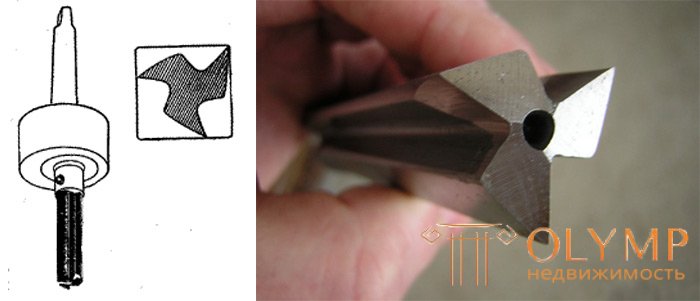

There is a special step drill, with which the drilling of both holes and the countersinking is performed simultaneously.

The confirmatte drill will allow you, without any difficulty, to drill a hole for the “euroscrew” in one operation in order to connect parts made of materials such as chipboard, MDF (MDF), plywood and an array. The main application of the drill under confirmatte found in the manufacture of furniture and joinery works.

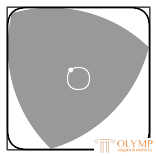

Yes, this is true: there are drills that allow drilling square holes, such exotic. Of course, a round drill will not help here, but a drill based on the Ryoulot triangle will do the job quite well. True square turn out with slightly rounded holes.

So, a drill with a cross section in the form of a Ryoulot triangle (see illustration below) and cutting edges that coincide with its tips, allows to obtain almost square holes.

The peculiarity of such a drill is that its center during rotation does not remain in place, as it happens in the case of traditional spiral drills, but describes a curve consisting of four arcs of ellipses. Therefore, the cartridge in which the drill is clamped should not interfere with this movement.

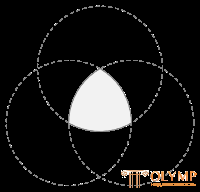

What happened inside when intersecting three circles is the Ryoulot triangle.

For the first time, Harry Watts, an English engineer who worked in the USA, managed to make such a construction. For drilling, he used a guide pattern with a square slot, in which the drill moved in a “floating cartridge”. Patents chuck and drill was obtained by Watts in 1917.

The sale of new drills made the firm Watts Brothers Tool Works. Another US patent for a similar invention was issued in 1978. Why with the help of such a drill it turns out exactly a square hole, you can look at the roller below, where the Reloo triangle rotates around a slightly moving axis.

Что бы оставить комментарий войдите

Комментарии (0)