For applying paint formulations use brushes of various sizes and shapes, rollers with a fur or foam cover, hand and electric spray guns with fishing rods, compressor painting units with spray guns. Spray guns can only spray non-viscous aqueous colorful formulations. Compressor paint units are used for applying paint formulations of any consistency and viscosity.

Hand tool . Brushes are used for painting with small amounts of work and in hard-to-reach places, in particular for painting frames. In this case, it is useful to use a piece of cardboard to protect the glass from paint contamination. The use of rollers increases productivity and contributes to a higher quality of work. Rollers can be with short and long handles, the latter are used when painting rooms without scaffolding. Coloring of individual parts, including complex outlines (carpentry, radiators) produced by various specialized brushes and rollers. The quality of adhesion of paint to the base will be higher if each layer is applied in three doses. This is more true for doors, window sills, slopes.

The paint is applied to a separate area of the painted surface and grind. At the second reception, the paint is smoothed on the surface with horizontal movements of the handbrake or the flautz, the third reception consists in the longitudinal (along the fibers) rubbing the paint into the surface being painted.

Spray guns and spray guns. On large areas, water-based paint compositions should be applied with spray guns (Fig. 12.4) and spray guns. Kraskoraspylitel includes a removable tank with a lower mount, which comes in a tube for supplying paint. Compressed air enters the tank and the spray head simultaneously. When you press the trigger paint under pressure comes from the tank to the spray head, in which compressed air carries and sprays the colorful composition.

The principle of the gun: under the action of compressed air paint through a rubber hose enters the bait and when it comes out of it splits, thereby evenly sprayed on the painted surface.

The application of the compositions of almost any viscosity carry compressor painting installations. The basis of the installation is an ink tank - a hermetically sealed vessel with a paint composition, in which an increased pressure is created by supplying compressed air to it. If the spray gun tank is combined, then the pressure created is enough to spray the paint composition. In more stationary installations, the compressed air from the compressor is fed through the first hose to the ink tank with paint; under the action of air pressure, the paint begins

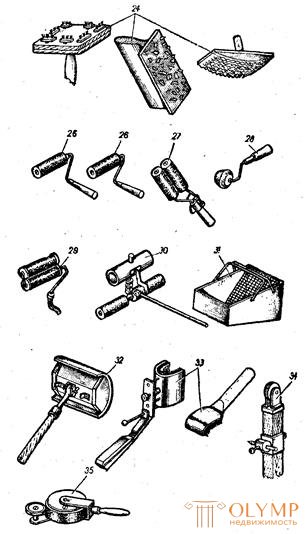

Hand tools for painting works / - figured scraper; 2 - scraper with an extended handle; 3-5 steel brushes; 6 - steel spatula SDS; 7 - steel spatula ShSh-180; 8 - spatula with a bath for ceilings; 9 — wooden trowel with a rubber or plastic tip; 10 — spatula with a replaceable blade; 11 - a combined trowel; 12 - an elongated wooden trowel with a plastic tip and an elongated handle; 13 - plastering | |

knife; 14 - rubber spatula; 15 - maklovitsa; 16 — stroke brush KM; 17 - handbrake brush; 18 - brush-fleyts; 19 - panel brush; 20 - whisper; 21 - trimming of ShchT-1 and ShchT-2; 22 - radiator paint brushes; 23 - composing trimming; 24 - textured trimming; 25 — roller type VM; 26 - the same, like VP; 27 - the same for coloring radiators, pipes and grilles; 28 - the same corner; 29 - the same, with a pneumatic feed; 30 — the same for coloring floors; 31 - bath with a grate; 32 - a device for grinding pipes; 33 - the same for surface grinding; 34, 35 - the same, for beating and grinding the panels | |

flow to the spray gun, where the second hose receives air from

Fig. 12.4. Pneumatic hand spray gun: 1-removable tank; 2-tube for supplying paint; 3- spray head; 4-needle; 5- conical nozzle opening; 6-body tip; 7 trigger; 8-spring; 9- needle regulator; 10-crank | compressor. Due to these two pressures, the paint composition is sprayed and applied as such to the surface. A stream of paint is directed perpendicular to the surface from a distance of 0.2 ... 0.3 m. The work with the spray gun must be trusted to a qualified worker, since an increase in paint pressure at the exit of the nozzle leads to excessive paintwork and fogging in the work area; a decrease in pressure reduces the quality of work, leads to a decrease in productivity and cost overruns. The spread method of airless application of synthetic paints was found, the essence of which is that the paint composition is fed under high pressure (4 ... 6 MPa) to the nozzle, where it acquires a speed higher than the critical one at a given viscosity. As a result, the coatings obtained are uniform in thickness and are characterized by high adhesion and good gloss. Turbo-compressor plants (air turbines), which are multistage (2, 3, and 4-stage) electrically driven painting units, are beginning to be increasingly used. Low pressure and a large amount of air supplied to spray paintwork material, reduce fogging, |

Spray guns have a set of interchangeable nozzles with a diameter of from 0.5 to 4.3 mm. Such a range of interchangeable nozzles makes these installations universal in the application of many types of paints and varnishes - from diluted varnishes on wood to highly viscous textured textures for facades. The use of extension nozzles allows staining in hard-to-reach places: half-closed and closed cavities, spaces behind radiators, etc.

Electrically driven airless spray systems are applicable for painting small areas when finishing ceilings, walls, and floor painting mainly indoors. Installations have a high coefficient of transfer of paintwork material, a clear form of paint stain, great performance. A distinctive feature of airless spraying is the absence of fogging. The resulting coatings have a more dense structure and they lack pores and air bubbles.

Airless spraying plants are also produced with a gasoline drive. They are most convenient during the autonomous work, for performance of insulating works on roofs, in cellars of buildings and on extended communications. On these installations provides simultaneous connection from 3 to 6 spray guns.

In the cold season, and for a more uniform deposition of insulation coatings and to intensify the process of their application to airless spraying installations, electric material preheaters are mounted that are capable of maintaining the temperature of the applied paint composition in the range of 40 ... 70 ° C. Such heaters allow working with highly viscous mastics and compounds (polymer compositions) even at low positive temperatures.

Synthetic paints in a high-voltage electrostatic field can be applied by electro- painting . The method is based on the properties of the particles of the paint composition with a negative charge to be attracted and deposited on a grounded structure having a positive charge. The method is used to finish reinforced concrete, metal and wooden building products and parts.

Paint compounds of all kinds should be applied only in a thin layer. If a substrate or a previous painting layer appears through the paint layer, then it is necessary to apply another coating layer to achieve the desired tonality of the coating.

Что бы оставить комментарий войдите

Комментарии (0)