After installation of sheets of drywall does not work completely smooth and smooth surface. The fact is that the sheets are joined during assembly, and these joints require additional finishing so that everything becomes smooth. But it's not only that. Seal of drywall joints helps to avoid cracking in the future. Without such a seal, cracks may appear on the finish coat. Proper execution of work saves you from many troubles in the future.

Content: [hide]

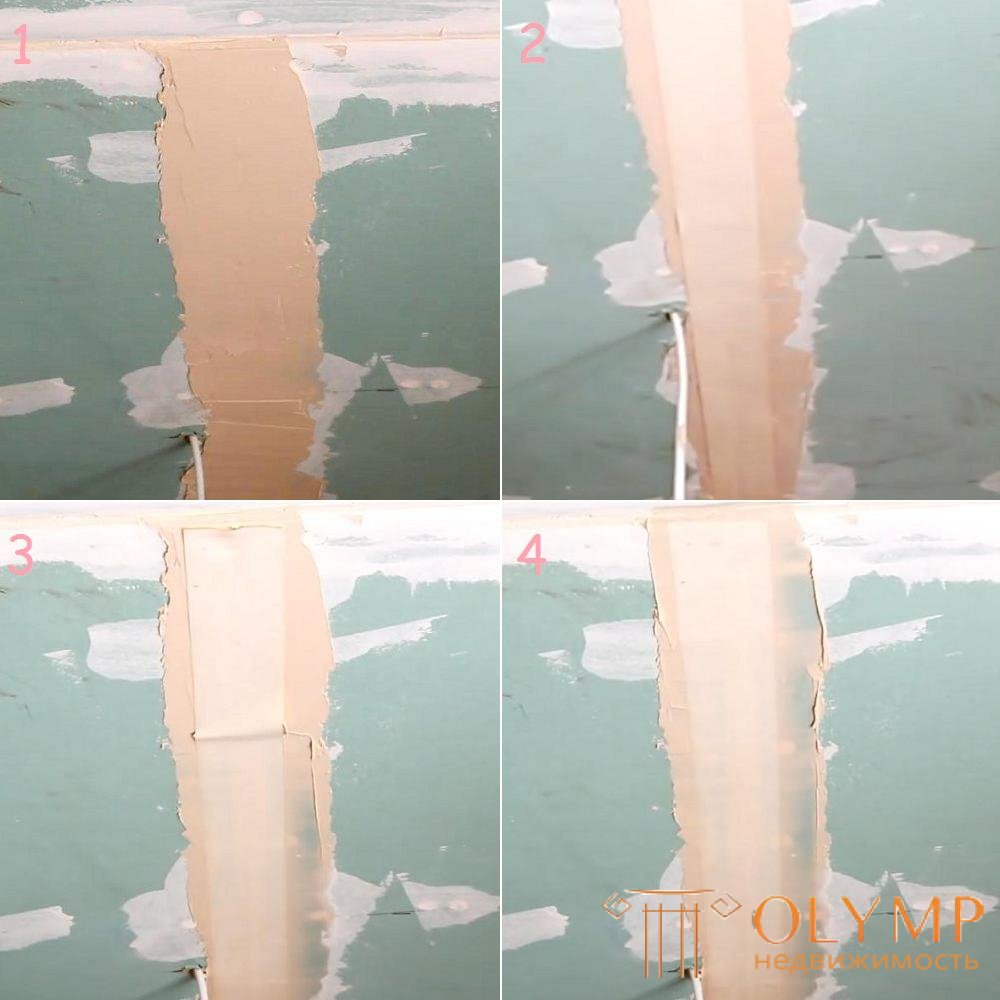

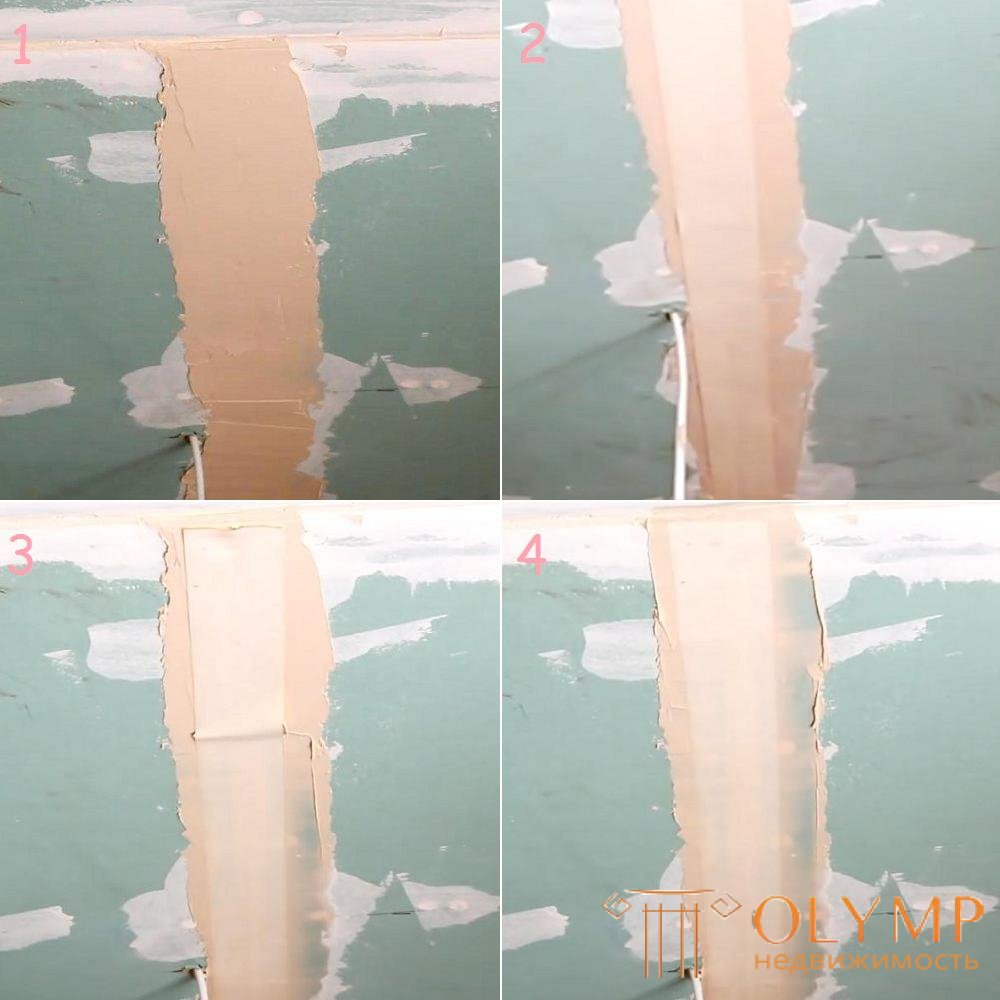

It looks like a wall with plastered joints

Sealing the drywall seams with their own hands is carried out for a number of reasons. Understanding why such a procedure is needed, it will be possible to execute it correctly. Many simply mechanically carry out a number of works without even thinking about the purpose of such actions. In fact, the grouting of drywall seams is performed for a number of reasons:

Before you close up the drywall joints with a solution, you need to carry out a number of preparatory work. These works include the preparation of sheets of drywall, the choice of working tools and putty.

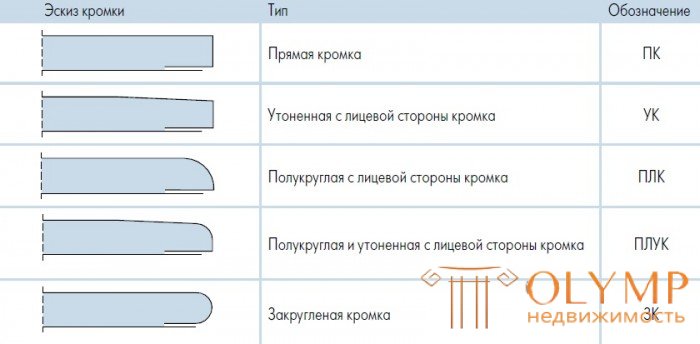

GCR with a semicircular edge is standardly used.

Preparatory work on the joints are reduced to chamfering. Chamfer is needed in order to create a small depression at the joints of the GCR. In this recess will be putty putty, which will make the joint of sheets more durable and reliable.

The drywall sheet already has a factory longitudinal edge. It does not need to touch. The edge is created with a knife only in those places where the gypsum component of the sheet is visible.

Putting the drywall seams with your own hands will require skills in creating the edge. To do this, the edge of a sheet of drywall is cut with a wallpaper knife at an angle of 45 degrees, creating a recess. You can also simply chamfer using a special planer at an angle of 22 degrees. Chamfering is carried out before fixing sheets of drywall to the surface. Cutting the edge with a knife can be done when the plasterboard is attached to the surface. The depth and width of the chamfer should be 5 mm.

Cut the edge (chamfer) can be a knife and a plane

The work will require the following tools:

Many wonder how to gloss over the seams of drywall? This question needs to be solved for itself even before the installation of drywall seams begins. Properly chosen putty is the key to continued success. Knauf putty is usually used. Traditionally choose a cheap and easy to use Fugenfuller. Sometimes Uniflot takes his place. You can choose something else if this is required by the future finish.

It is not enough to know how to putty drywall joints, because the primer also plays an important role. A deep penetration primer is used to clean the surface, as well as for better adhesion. With the help of a brush, the primer coats all the joints, and it does not matter what edge they are (factory or homemade). The primer will serve as a link, a kind of glue, between the drywall and the putty. It is necessary to wait until the primer dries completely.

Roller for priming seams is not suitable, as it will not be able to penetrate into the cracks between the sheets of drywall.

Properly mixed putty will be the key to successful work. Fugenfuller is a popular putty for drywall seams. However, not everyone chooses it because it dries quickly. Although this statement is doubtful, you need to be able to knead the solution. First, you need to knead the solution in small portions, counting your strength. Secondly, if everything is done correctly, then the putty will not dry for 30-45 minutes. And this is quite enough for comfortable work.

The required amount of water is collected in a clean bucket (you need to watch the putty instruction) and then the finishing putty is added there. It should be poured as if it were flour. If you throw everything in a pile, then problem lumps are guaranteed. Many argue about how it is better to seal the seams on drywall, without thinking about how they make this mixture.

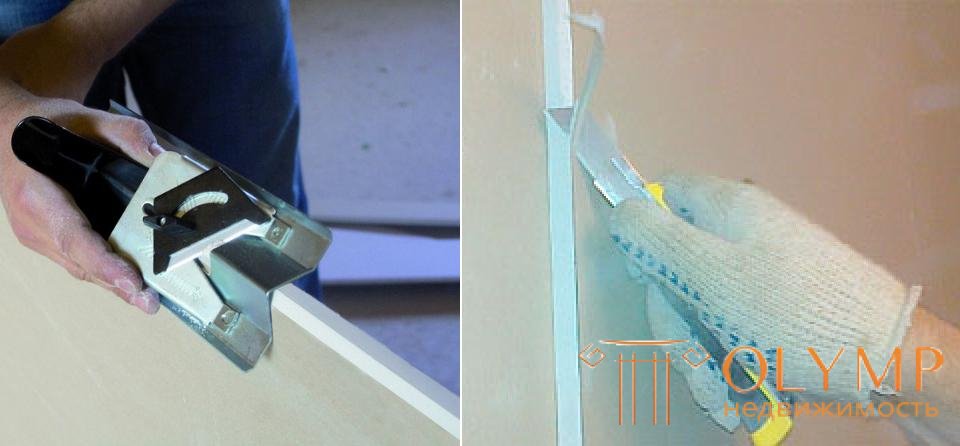

In the process of creating a mixture for sealing joints

After the putty is carefully poured into a container of water, it is mixed with a spatula. Using a mixer will result in a more rapid solidification of the mixture. Fugenfuller needs to be mixed a little so that the entire putty is soaked, and then leave it to swell for 5-10 minutes. After that, the putty for sealing the seams of drywall is thoroughly mixed with a spatula, and all the lumps are broken. The final mass should look like a very thick sour cream. With the mixture you need to start work immediately.

Sealing of drywall seams is performed using various spatulas. Standardly mix the mixture with one spatula and overlap with another. Or it is typed on one spatula and is held in hand. The second putty spatula is taken from the first as needed. This scheme allows you to work faster, without being distracted by constantly picking up the solution from the bucket.

Putting the drywall joints with your hands begins with filling the gap between them. Many people like to work in haste, putting a serpyanka or a paper tape on the seams, and on top of it is already a layer of putty. This technology, though it speeds up the work, but is fraught with consequences.

If a thin-layer textured plaster is eventually applied to such a surface, it will eventually crack in places of joints where voids remain. Also, with this method, problems may arise when cutting wallpaper in the corners, when the knife may fall into the void from pressure.

The first work will need a 20-centimeter trowel. It is used as it is necessary to seal the seams between sheets of drywall as quickly as possible. A sufficiently large amount of solution is accumulated on its surface to fill the voids between the joints with it. The tool is applied to the mixture across the seams, trying to drive it into the joints as much as possible.

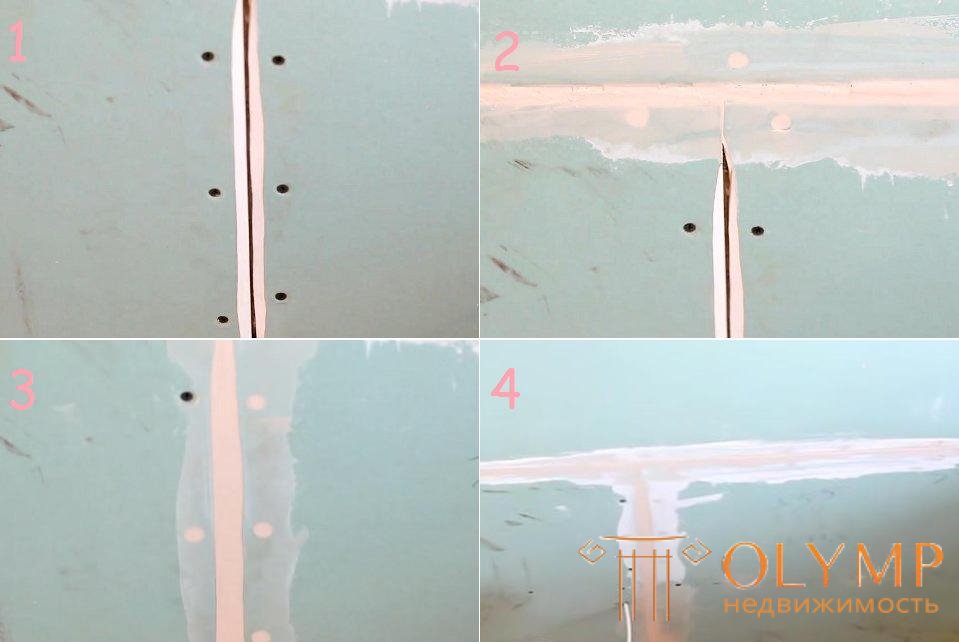

Seal drywall seams on the factory edge and manually made chamfer

It is necessary to completely fill the joints between the trim and factory edge. In this case, you should not leave the influxes on the drywall. It should remain smooth. After that, you can putty all the screw caps with a putty, you still need to give time to the solution so that it dries. The putty will be slightly retracted and then even a hollow can form at the site of the seams.

This technology is used by those who want to know how to properly seal the joints in drywall. If you do not fill the voids with a putty with voids, and immediately apply the solution, and then the reinforcing tape, then as a result, tubercles may form at the joints. Therefore, at first, voids are filled, and then paper tape or serpyanka is applied.

For many, puttying drywall seams using perforated paper tape is unacceptable. Like, it is much warped, and the joints are obtained curves. To avoid this, the tape is dipped in water for a while. Then it is removed, remove excess water and glue the joints. Sizing begins with a cut seam.

To use a paper tape or a special grid everyone decides for himself. Who is comfortable and who is accustomed to work with what. In any case, do not immediately try to glue sections of a length of more than 2.5 meters. This is very inconvenient and difficult.

Many are interested in the question of how to putty drywall seams with tape. Its use is a direct continuation of the above-described technology of filling joints with putty. When the solution dries, the seam will need to be coated again with a layer of putty. To do this, use a 20-centimeter trowel, on which a solution is applied with a 10-centimeter trowel.

The tape sits as tightly as possible to the drywall

Sealing drywall seams with reinforcing tape will help make the joints more durable. To do this, just put the putty tape is applied evenly in the center of the joint. She is pressed against the drywall 8-centimeter trowel. It is with such a spatula that it is best to squeeze the tape underside solution. Also such extrusion aligns the tape if it forms a wave somewhere. For this reason, the gluing of drywall seams starts from the corner. Speaking putty stretched in all directions with a wide spatula. But the putty of drywall joints is not yet complete.

After drying no hills should be

The tape is attached to the drywall, but it still needs to be covered with a layer of putty. Such a finishing finish reinforcing tape. The putty is smeared with a thin layer at the joint, pasted over with tape. If everything is done correctly, then there will be no bumps on the work site.

Что бы оставить комментарий войдите

Комментарии (0)