Toxicity - toxicity, ie, the ability to exert a harmful effect on a living organism. The presence of toxicants, i.e., chemicals with toxic properties, leads to destabilization of ecosystems and possible death of all living things.

A new branch of scientific knowledge that studies the effects of toxicants on the environment, on humans and biota, has been called ecotoxicology. The central element in it is the study of the effects of toxicants on human health.

The toxicity of building materials is assessed by comparing their composition with the MPC of toxic substances and elements released. Of paramount importance is the hazard class, the composition of harmful substances and their quantitative content. In terms of toxicity, polymeric building materials are the main source of environmental hazard in residential buildings.

General concepts of polymers

In modern construction polymeric construction materials (there are over 100 items) are becoming more widely used.

Polymers are high-molecular compounds, the most important component of plastics. The raw material for the production of polymers is natural gas, as well as “associated” gas that accompanies the oil outlets and coal tar obtained during the coking of coal.

They consist mainly of three groups of chemical compounds:

1) a binder (various resins, polystyrene, phenol-formaldehyde compounds, etc.);

2) plasticizer;

3) filler

As auxiliary substances they also include pigments (dyes), stabilizers, etc.

For the first time, industrial production of polymers began in the 20s – 30s. The twentieth century, when urea-formaldehyde and some other types of polymers began to be mass produced.

With the introduction of polymerization methods (starting from the 30s), new types of them were obtained: polyvinyl chloride, polystyrene, polyvinyl acetate, etc. Even later, polycondensation plastics appeared: polyurethane, polyamide, etc.

Large-scale production of polymeric materials and their widespread use in construction began in the 60s. Currently, more than 100 million tons of polymers are produced in the world, a significant part of them is used in construction. For example, in CIIIA and Germany, more than 25% of polymers are used to make building and finishing materials. In the last decade, the production of such important polymers as polyethylene, polypropylene, polyvinyl chloride and polystyrene has increased dramatically. Polymers are increasingly used as the most important component of composite materials, for example, polymer concrete, polymer cement concrete, etc.

The widest use of polymers in construction, in addition to such positive properties as anti-corrosion, elasticity, flexibility, manufacturability, is primarily due to the ability to create materials from them with the properties specified by developers

The range of application of polymers in construction is very wide. They are universally used for: flooring (linoleum, relin, PVC tiles, etc.), interior decoration of walls and ceilings, waterproofing and sealing buildings, making heat - and sound insulation materials (foam plastics, foam plastics, honeycomb plaster), roofing and anti-corrosion materials and coatings , window blocks and doors, structural finishing and enclosing elements of buildings, varnishes, paints, enamels, adhesives, mastics (on a polymeric binder) and for many other purposes

Toxicity and other negative properties of polymeric materials

In assessing the environmental cleanliness of polymeric building materials are guided by the following basic requirements for them:

• polymeric materials should not create a persistent odor in the room;

• release volatile substances into the air at concentrations dangerous to humans;

• stimulate the development of pathogenic microflora on its surface;

• worsen the indoor climate;

• should be available wet disinfection;

• field strength of static electricity on the surface of polymeric materials should not be more than 150 V / cm (at a relative humidity of 60–70% in the room air)

Numerous studies have shown that almost all polymeric construction and finishing materials created on the basis of low molecular weight compounds, during use, can release (migrate) toxic volatile components, which upon long-term exposure can adversely affect living organisms, including human health.

The International Agency for Research on Cancer (IARC) draws attention to the carcinogenic risk of polymers derived from petroleum and hard coal, and the Agency for Toxic Substances and Diseases Registration (ATSDR) states that plastics use substances that are included in the list of the twenty most dangerous toxic substances.

We give the characteristic of some polymeric building and finishing materials capable of releasing toxic substances.

Chipboards emit formaldehyde in 2, 5—3 times and more than the permissible level. In the free state, formaldehyde is an irritant gas with general toxicity. It inhibits the action of a number of vital enzymes in the body, leading to diseases of the respiratory system and the central nervous system.

Fiberboard (Fibreboard), chipboard (particleboard) and fiberboard (particleboard). Phenol and formaldehyde are released into the indoor air environment. The concentration of formaldehyde in residential premises equipped with furniture and building structures containing chipboard may exceed the MPC by a factor of 5–10. A particularly high excess of the permissible level is noted in prefabricated panel houses. The toxicity of released substances depends largely on the resin grade.

Like other types of resins: carbamide, phenolic, furan and polyurethane, epoxy resins contain volatile toxic substances: formaldehyde, dibutyl phthalate, erichlorohydrin, etc. For example, polymer concrete (PB) based on epoxy resin Ed-6 with the introduction of the plasticizer MGF- 9 reduces the release of ECH and can only be recommended for industrial and public buildings.

PVC - linoleums have a general toxicity, during operation they can create on their surface a static electric field of strength up to 2000–3000 V / cm. When using polyvinyl chloride tiles in the indoor air environment, phthalates and brominating agents are detected. Very negative property of the tiles - low heat-shielding properties, which leads to colds. Recommended only in ancillary rooms and corridors.

Rubber Linoleum (Relin)

Regardless of the duration of stay in the room produces an unpleasant peculiar smell. Styrene rubber linoleums secrete styrene. On its surface, relains, like all plastics, accumulate significant charges of static electricity. It is not recommended to cover with floor in living rooms

Nitrolinoleum

Allocates dibutyl phthalate and phenol in quantities exceeding the permissible level

Polyvinyl acetate coatings (PVA)

In case of insufficient ventilation, formaldehyde and methanol are emitted into the air in the rooms in an amount exceeding the MPC by 2 times or more.

The most dangerous solvents and pigments (lead, copper, etc.). In addition, paint and varnish coatings pollute the air environment of residential premises with toluene, xylene, butyl methacrylate, etc. Toxic bitumen mastics, made on the basis of synthetic substances, contain low molecular weight and other volatile toxic compounds

Scientists at the Institute of Building Ecology in Sweden are among the most dangerous chemical compounds released into the atmosphere from polymeric building materials, isocyanates, cadmium and flame retardants

Isocyants are hazardous toxic compounds that enter residential areas from polyurethane materials (seals, compounds, etc.). According to Swedish experts, polyurethane foam is very convenient in operation, but it may be unsafe for future homes. The harmful effects of isocyanates, leading to asthma, allergies and other diseases, are enhanced by the heating of polyurethane materials by sunlight or heat from heating batteries. The possible release of isocyanates into the atmosphere requires constant monitoring, however, according to Swedish specialists from the Institute of Building Ecology, the existing methods are insufficient, and new ones are still under development.

Cadmium is very dangerous - a heavy metal contained in paintwork materials, plastic pipes, floor coverings, etc. Once in the human body, it causes irreversible changes in the skeleton, leads to kidney disease and anemia

Another environmental threat emanating from polymeric building materials is fire-fighting agents - flame retardants contained in non-combustible plastics. The connection of harmful substances released from them, and with the disease of the population with allergies, bronchial asthma, etc.

Conducted in recent years, detailed studies have shown that polymeric building materials can be a source of emission and such harmful substances as benzene, toluene, xylene, amines, acrylates, etc.

The migration of these and other toxic substances from polymeric materials occurs as a result of their chemical degradation, i.e., aging, both under the influence of chemical and physical factors (oxidation, temperature drops, insolation, etc.) and due to the insufficient ecological purity of the raw material, violation of the technology of their production or use for other purposes. The level of emission of gaseous toxic substances increases markedly with increasing temperature on the surface of polymeric materials and relative humidity of the air in the room.

One of the possible sources of deterioration of the ecological condition of residential premises is the resettlement of microflora (fungi, moss, bacteria, etc.) on the surface of polymeric materials. Some of the plastics act on microorganisms detrimental, others, on the contrary, have a stimulating effect on them, contributing to intensive reproduction. How dangerous is their property, can be judged by the time of preservation on the surface of the floors of polymeric materials of pathogens:

diphtheria - 150 days, typhoid and dysentery - more than 120 days

In this connection, only such polymeric materials are used in medical institutions and public buildings that have bactericidal properties, for example, polyvinyl acetate emulsion based floors

No less dangerous is the ability of polymeric building materials to accumulate charges of static electricity on its surface. This problem is extremely important, given the likelihood of a combined effect on the body of the electrified polymer and other negative factors.

In particular, it was found that the electrifiedness of polymers has a stimulating effect on the development of pathogenic microflora, and also contributes to easier penetration of volatile toxic substances that have received an electric charge into the body.

Particularly high degree of electrification (more than 65 V / sq. Cm) distinguishes the surface of linoleum on PVC base and other plastic-based floors.

An antistatic agent, i.e., a chemical compound that neutralizes charges of static electricity, forms a rubber-like film on the surface of a polymer material. For these purposes, various nitro compounds (amines, amides, etc.), polyglycols and their derivatives, sulfonic acids, phosphorus-containing acids, etc. are used. The choice of antistatic agent is determined by the purpose and type of polymeric material. Recently, in the preparation and laying of polymeric facing materials, the removal of electrostatic charges from their surface is also carried out with the help of neutralizers of static electricity - NES / A and others

The release of gaseous toxic substances from the combustion of polymeric building materials is another very serious danger associated with their use. It is enough to point out that thermal decomposition when burning 1 kg of polymer gives so many gaseous toxic substances that they are enough to poison the air in a room of 2000 m. In a person in that room, after 10-15 minutes, severe poisoning or even death occurs.

Combustion products of polymeric materials are toxic substances such as formaldehyde, hydrogen chloride, carbon monoxide, etc. When burning foams, a very dangerous gas is released - phosgene (in the first world war it was used as a poisonous agent of asphyxiation) when thermally decomposed polystyrene foam is hydrogen cyanide , gaseous styrene and other equally dangerous products

It is known that during a fire in the Moscow hotel "Russia" in the late 70s. the main cause of death for many people living there was not thermal burns, but toxic poisoning during burning of facing polymeric and paintwork materials

It follows from the above that, under normal conditions, the elimination of waste polymeric materials by simply burning them is completely unacceptable. During the combustion of polymeric materials, in addition to the above-mentioned phosgene, hydrogen chloride and hydrogen cyanide, formaldehyde, carbon monoxide and styrene gas, highly toxic substances such as hydrocyanic acid (hydrocyanic acid) are formed (destructive for all living things already at concentrations of more than 0, 3 mg / l ), hydrogen halides, nitrogen oxides, etc

An alternative option for simple combustion is thermal processing of polymeric materials in special chambers to obtain secondary materials from them.

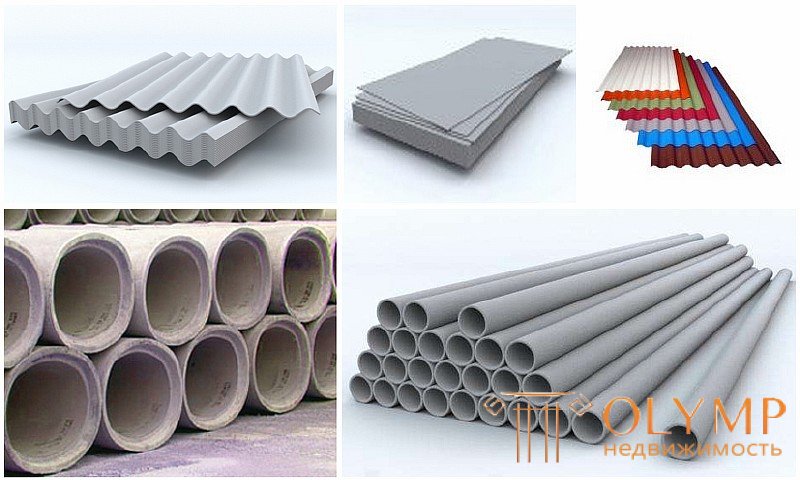

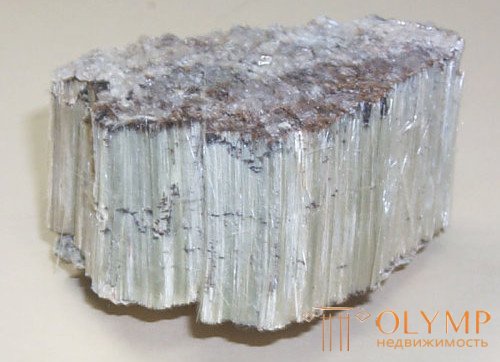

Asbestos is a natural fine-fibrous material of a group of silicates. There is white chrysotile and amphibole asbestos, photo 1 . Asbestos fibers are thin and flexible and have sufficient tensile strength. Asbestos is added to cement and other mixtures in the production of building materials and products.

Photo 1. White asbestos (chrysotile)

Asbestos is used in various industries:

Asbestos is produced in the construction industry,

Chronic asbestos poisoning develops for a long time and is caused not so much by the mineral itself, as by the structural disorders that it causes, accumulating in the lungs.

Inhalation of asbestos dust, which is formed during the production of this material or the mechanical destruction of products from it, part of the fibers enters the lungs. Due to the fact that chrysotile asbestos dissolves even in a weakly acidic environment, its accumulation in the lungs requires a significant dose of dust and a long time of exposure to it on the body. And even in this case, the harm of asbestos to a person can manifest itself in ten or more years.

The development of bronchitis is most likely caused by mechanical irritation of the respiratory tissue tissues with microfibres. It is also possible that the development of asbestosis - in this disease, dust that has settled in the lungs causes cicatricial changes in the lung tissue.

What is harmful to health asbestos in terms of cancer? It has been established that it is not in itself a carcinogen, but belongs to a group of promoters - substances that contribute to the effect of carcinogens on cells. It is associated with a rare cancer - mesothelioma.

Construction is always connected with concrete, and concrete is created from such material as cement. Cement production today remains a difficult process. Therefore, you should find out whether there is harm to cement and cement dust for human health?

Previously, as a binder, eggs were added to the mortar mixtures, they performed the adhesion property. This is an environmentally friendly product. Today in concrete and mortar put cement. Without this building material it is impossible to imagine any modern construction or repair in the house. Concrete or other derivatives of cement are present in almost every home, and is absolutely harmless to humans, it is an environmentally safe component. But the cement from which make concrete, has a negative impact on human health.

Special danger is posed to construction workers. When working with cement, there is always dust that rises into the air. The builder automatically receives "blows" on the body from three sides: eyes, skin, lungs. Cement dust primarily affects the eyes. They often begin to water, thereby protecting the body from external stimuli. Over time, the protective properties are destroyed, which leads to blindness.

Далее под «ударом» находится кожа. Если кожные покровы тела не будут защищены специальной одеждой, то цементная пыль начнет осушать кожу человека, поглощая из нее влагу. Таким образом, кожа становится сухой, появляются трещины и ранки, которые в дальнейшем могут кровоточить. Данный процесс является весьма болезненным и неприятным, и может повлечь за собой инфекционные заболевания.

Самая опасная область, куда может попасть цементная пыль – это легкие. Мягкая легочная ткань постепенно становиться огрубевшей. Воздействие стройматериала является очень опасным для здоровья человека. При попадании цементной пыли в легкие начинается необратимый процесс разрушения.

Структура легких меняется и появляется хронический бронхит или астма. Этот процесс происходит постепенно, и человек может не сразу почувствовать негатив. Через некоторое время начинают появляться заболевания, в процессе специалисты начинают выяснять, что эта болезнь связана с применением цемента, поэтому зачастую в конечном итоге ставится диагноз в результате профессионального заболевания.

Работодатель начинает выяснять обстоятельства и проводить необходимые расследования, а это очень сложный процесс. В любом случае ничем хорошим он не завершается, а наоборот работнику оформляют инвалидность, а работодателя облагают немалыми штрафами. Почему это все происходит? Дело в том, что работодатель не выдал работающему средство индивидуальной защиты – респиратор, или выдал, но не проконтролировал, что тот его применяет.

То есть вина в этом случае работодателя. Но если респиратор или маска были выданы своевременно и это можно доказать подписью работника в карточке выдачи спецодежды, да еще и постоянно предупреждали об использовании этой маски тоже письменно под личную подпись, то здесь точно виноват сам работник. Что делать во втором случае, решает представитель министерства здравоохранения.

При отсутствии полноценной защиты для работника стройки, его жизнь находится в опасности. К тому же, негативное воздействие оказывается и на растения. Пыль покрывает листья сверху. Тем самым препятствует проникновению солнечных лучей. Процесс фотосинтеза не происходит и растение в скором времени погибает. Поэтому однозначно, вред цемента и цементной пыли на здоровье человека и растения присутствует. В случае если не остановить агрессивное воздействие пыли, может наступить смерть.

Чтобы исключить контакт цементной пыли с организмом человека необходимо научиться правильно пользоваться средствами индивидуальной защиты и спецодеждой. Для защиты органов дыхания необходимо применять маски или респираторы. Чтобы защитить глаза от цементной пыли нужны очки. Для защиты кожного покрова необходимо надеть спецодежду и спецобувь.

Одежду следует застегнуть на все пуговицы, куртку заправить в брюки и только тогда приступать к выполнению работ. Важно помнить, что ваша безопасность находиться в ваших руках, и никто другой не спасет вас от воздействия негативных факторов, как бы он этого не хотел и не желал. Вы вправе отказаться от выполнения трудовых обязанностей, если вас не обеспечили средствами СИЗ и спецодеждой.

In conclusion, it should be emphasized that in construction, for reasons of environmental safety, only those polymeric materials and products (cladding, molded products, adhesives, mastic, etc.) can be used, which meet the requirements of current GOSTs and TU and have satisfactory sanitary and hygienic indicators

For example, the following types of polyvinyl chloride coatings are recommended for flooring: on a heat insulating base (GOST 18108-80), on a fabric base (GOST 7251-77), baseless (GOST 14632-79) and PVC floor tiles (GOST 16475-81), as well as foamed linoleum (TU 21-29-102-84), decolin (TU 21-29-103-84), carpet (TU 400-1-184-79)

For the installation of partitions and flooring, chipboard plates were allowed on an organo-mineral binder (TU 110-128-90), and chipboard - on a phenolic-formaldehyde binder (TU 0 and TU 674045-90) of the Krasnoyarsk plant. The remaining plates were not allowed to be used in residential areas due to their toxicity.

Currently, the release of the “List of polymeric materials and products approved for use in construction” has been discontinued. Each type of new polymer building materials and products now requires GOST and a separate hygienic certificate. The use of polymeric materials that are in the thickness of structures and communicating with the air of the premises only through joints and cracks, as well as adhesives and other low-toxic materials used in small quantities, is not regulated or limited. This provision does not apply to highly toxic substances, for example, such as isocyanates released from polyurethane seals, which even in very small doses can lead to respiratory diseases and allergies.

Along with hygienic regulation and certification, the development of new types of non-toxic polymeric building materials and products is crucial for improving the environmental safety of the materials used. The greening of the technological process of their manufacture, strict control over the quality of the raw materials

From an environmental point of view, the general trend in the use of polymeric materials in construction should be as follows: it is necessary to apply nontoxic as widely as possible, to limit the use of low-toxicity and to avoid toxic materials.

Что бы оставить комментарий войдите

Комментарии (0)