For waterproofing swimming pools, reservoirs, basements, a dense, waterproof gunning plaster is used, which is applied using a cement gun by gunning. This method consists in the fact that a jet of a solution under pressure of compressed air hits the surface and a layer of shotcrete plaster 15-25 mm thick is formed. 28 days later. hardening in natural conditions of sprayed plaster reaches a tensile strength of 1.5 MPa.

Gunnery plaster is applied using the unit, which consists of a cement gun, air cleaner, water tank and compressor. The main machine is a cement gun. Regardless of the design of cement guns, the principle of their operation is the same.

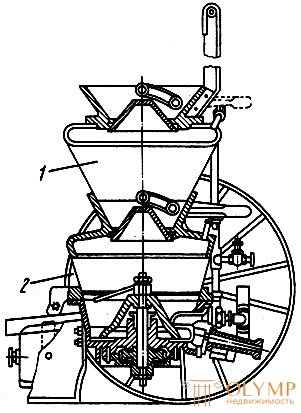

Cement-gun (Fig. 99) consists of the upper 1 and lower 2 truncated cones-tanks, or chambers, connected in one piece. The upper tank has a feed hopper through which it is filled with a dry mixture. From the outer side of the body passes the steel pipeline; flexible hoses are connected to it from the compressor. Compressed air is fed through these hoses into the cement cannon.

Fig. 99. Cement Cannon: 1.2 - Tank Cones

To clean the compressed air blown into the cement gun by the compressor, an air cleaner serves. It is a welded cylinder, in the upper part of the bottom of which there is an inlet. It connects to a hose for supplying compressed air from the compressor. In the lid is located the outlet to which the air hose is connected, which supplies compressed air that has been cleaned of water and oil to the cement cannon. Inside the air cleaner is arranged porous filter.

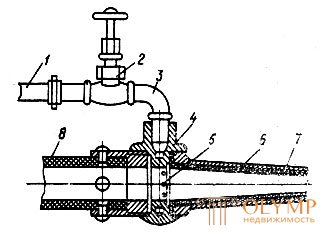

To connect the cement gun, air cleaner, water tank and compressor, as well as to feed the workplace from the cement gun to the dry mix nozzle, and from the water tank of water, use rubber hoses. Hoses through which a dry cement-sand mixture is supplied are called material, through which air is supplied — air, and through which water — water.

Material hoses produce a diameter of 25-38 mm. It is more expedient to use hoses with a diameter of 32 mm. The use of hoses of smaller diameter reduces the performance of cement gun and leads to the rapid formation of traffic jams. Water hoses are used with a diameter of 13 mm. The links of the hoses are connected by screwed couplings. Hoses with rivets or countersunk head bolts. Connections must be strong and tight so that the hoses do not allow air to pass through.

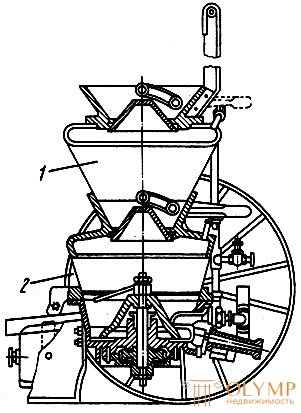

A nozzle is used to mix the dry mixture with water and apply the solution to the surface (Fig. 100). The nozzle consists of a housing 4 and an annular chamber with inserted mixers 5. The mixer is a ring with eight oblique-radial holes. A metal conical barrel 6 with an internal rubber liner 7 protecting the barrel from rapid abrasion is attached to the mixer body from the front. A material hose 8 is attached to the rear of the housing, through which a dry mixture is fed into the nozzle. A nozzle 3 with a valve 2 is attached to the body at the top, a water hose 1 is attached to the valve. Water supplied from the nozzle enters the mixing chamber in trickles and, meeting with the cement-sand mixture, mixes and a solution is formed. The solution is ejected with compressed air from the nozzle to the surface, penetrates into all its irregularities and is firmly connected to it.

Some cement guns work without an air cleaner, which makes the unit more compact. The water pump of this cement gun can supply water under the necessary pressure to the nozzle from any source.

Fig. 100. Nozzle for applying the solution: 1 - water hose, 2 - valve, 3 - tube, 4 - body, 5 - mixer, 6 - tapered barrel, 7 - rubber liner, 8 - material hose

Dry mix for gunning plaster is usually prepared on stationary installations and delivered by car to the place of work. At the construction site the mixture is prepared in mixers and as an exception on the striker manually. To protect the dry mixture from moisture, it is stored at the work site in a chest with a tight-fitting lid. Before use, the mixture is sieved through a sieve with 8 x 8 mm cells. This mixture is well transported through the hoses.

For the preparation of gunning plaster used cement brands 300 or 400 m and river sand. The ratio between cement and sand ranges from 1: 1 to 1: 8. The sand must be dry and clean; sand pollution reduces the strength of gunning plaster. Allowable sand moisture 6-10%. If its humidity is less than 4%, sand should not be used, since the prepared mixture will be stratified during transportation through the material hoses. The overdried sand does not mix well with water in the nozzle, it turns out uneven in composition cement mortar. The use of excessively fine sand lowers the strength of the sprayed plaster. To speed up the setting of the shotcrete plaster, additives of calcium chloride or water glass are added to the mixture. Calcium chloride is injected no more than 5% by weight of cement. Calcium chloride is used only in conditions of low temperature (below + 5 ° C). Liquid glass is injected in the amount indicated by the laboratory. In order to obtain greater water resistance in shotcrete plaster, ceresite is added in a ratio of 1:10 (1 part ceresite and 10 parts water) or sodium aluminate from 1: 6 to 1:15, where from 1 hour they take 6 to 15 hours. water. These chemical additives are dissolved in water and poured into the dosing tank.

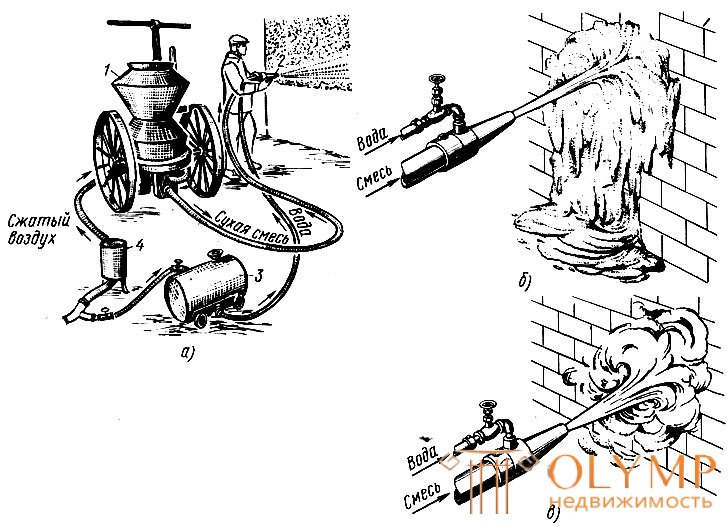

Before starting work, install a unit for shotcrete (Fig. 101, a): near cement-cannon 1 air cleaner 4, water tank 3 and a little further on the compressor. From the compressor hold the hose with two branches. One end is connected to the air cleaner, the other to the water tank. From the air cleaner hose connected to the cement gun. A material hose is connected to the nozzle from the cement gun, and a water hose is connected from the tank. After installation of the unit, it is checked how it works and if it does not let air through.

Fig. 101. Gunning of surfaces: a - unit operation, b, c - solution jets with excess and lack of water; 1 - cement gun, 2 - nozzle, 3 - water tank, 4 - air cleaner

Cement-sand mixture is loaded into the upper chamber of the cement gun, under the action of its own gravity, the mixture is poured into the lower chamber. The shutter closes and compressed air is let into the chamber. The mixture is served with a distributor plate to the nozzle. Compressed air passing through the nozzle picks up the mixture and blows it through the nozzle and the material hose to the nozzle. As soon as the loosened, suspended in the mixture, picked up by a jet of compressed air, comes to the nozzle, it is moistened with water, mixed in the mixer, turns into a solution and ejected by a strong jet from the nozzle.

The amount of water supplied to the mixer is regulated by a valve. The dosage of water supplied to the mixture is checked by the color of the jet ejected from the nozzle and the sprayed plaster applied. With an excess amount of water (Fig. 101, b), a liquid solution is obtained, sliding down from the applied surface. With a lack of water (Fig. 101, c) in the mixture, the solution is not fully wetted and when ejected from the nozzle it is very dusty.

The shotcrete of surfaces is performed by a link consisting of two plasterers of the 4th category, one plasterer of the 3rd category and the driver of the 4th category. The duties of the link include washing the shotcrete surfaces with water, preparing the dry mixture, loading it into the cement gun and gunning.

The driver observes the work of the cement cannon, the air pressure that must correspond to that specified in the passport of the machine, and the presence of water in the tank; periodically 3-4 times a shift, he should blow the air filter. In addition to controlling the cement gun, the machinist also takes part in loading the cement gun with the mixture.

Plasterer of the 4th category flushes the surfaces, manages the preparation of the mixture, applies a layer of mortar to the surface, tightens and cleans the hoses, identifies the resulting mortar plugs and eliminates them, monitors the quality of work and performs various auxiliary works.

The second plasterer of the 4th grade helps the first one and, if necessary, replaces it, in addition, it is connected between the plasterer and the machinist. With plasterer of the 3rd category, he prepares a dry mix and loads the cement gun. If the dry mixture is prepared on the spot, "the 3rd category plasterer delivers sifted sand and cement to the work site, pours them onto the firing pin, and together with the 4th category plasterer shovels the prepared mixture and loads it together with the machinist into the cement gun.

If the surface of the gunning plaster is required to wipe, then plasters of the 3rd or 2nd category are additionally attached to the link. At performance of the improved plaster plasterer of the 3rd category works, idle time - the 2nd category.

For work it is necessary to prepare such an area that could be plastered during one shift. The surface is cleaned in advance, and before applying the sprayed plaster only moistened with water. Plastering recommended from the top down. The thinner the applied layers of plaster and the more of them, the stronger the current-plaster and the more reliable it will provide water and gas impermeability. Each new layer is applied to the previous one after it grabs, but not earlier than in 60 minutes. The first layer of sprayed plaster is most often applied with a thickness of 15 mm, then it is leveled, cutting off irregularities with a spatula or trowel. The first layer is kept for 24 hours, then it is moistened with water and the second layer is applied.

When gunned, the nozzle is kept perpendicular to the surface at a distance of 70-90 cm from it. Smaller grains of mortar are more quickly clogged up in the pores and shells and are primarily deposited on the surface; larger grains of sand, hitting small ones, compact them, but at the same time partially rebound. With the buildup of the sprayed plaster layer, large grains of sand also begin to sink into it.

First, the amount of coarse sand that bounces reaches 20-25%, but gradually, as the layer is applied, it decreases. Mostly grains of sand without a cement layer bounce off, so that the loss of the binder is negligible. Before starting work, the joints of the shotcrete sites are cleaned of settled dust and moistened with water.

To avoid shrinkage cracks and increase the resistance of the applied shotcrete plaster, gunned areas should be protected from drafts of excessive solar heating and mechanical damage. It is best to cover the surface with two or three sheets of canvas that overlap one another. Tarpaulin should be pre-moistened with water; To permanently moisten the tarp over it, they arrange a perforated tube through which water flows. Where the sprayed plaster is used in the form of ordinary plaster, it is recommended to moisten it for 5-7 days.

Every day after work, the cement cannon, hoses and nozzles should be cleaned: first flush with compressed air, and then, without disassembling the machine, clean all accessible places. Regularly, at least once a week, it is necessary to disassemble, clean and lubricate the machine, and wash its individual parts with kerosene.

Prior to the commencement of work, the crew serving the cement cannon should be instructed in the labor protection regulations.

Since an almost semi-dry mixture is thrown out of the cement cannon, plasterers should work in glasses and respirators, in tight workwear and mittens. When working at height, workers are required to wear safety belts and attach themselves to reliable structural elements of buildings. Plasterer should carefully ensure that no one gets hit by a shotcrete plaster.

All electrical cables leading to the unit must be carefully insulated and laid in the box if they pass on the ground, or are suspended above the height of a person, since the unit operates from a lighting network of 220 V.

Before starting work, the plasterer is obliged to check all hose connections, in the process of work, ensure that the air pressure in the cement gun does not exceed that indicated in the instructions.

During the liquidation of the solution plugs, workers who are not associated with this operation are prohibited from being near the hoses; The nozzle and the open mortar hose must be directed away from the workers.

When disconnecting the hose, pressing the assembled unit and testing it, there should be no unauthorized persons near the unit.

Что бы оставить комментарий войдите

Комментарии (0)