Strengthening at overloads . The need to strengthen stone walls of pillars occurs when mechanical damage to the masonry, overgrowth of openings, the elimination of intermediate floors, excessive loads, the presence of cracks or other signs of deformation, etc. The consequence of each of the reasons is overloading of the working sections of the masonry, either eccentrically crimped or repeatedly reducing the carrying capacity, for example, when the instruction is stratified into separate flexible elements. Therefore, most types of strengthening walls and pillars is to ensure the local stability of the compressed masonry.

The traditional method of strengthening is the device of the external "corset" or clips that prevent the horizontal "spreading" of the masonry. The posts of pillars and narrow walls represent a system of several angular profiles, combined by horizontal strip ties, whose pitch depends on the flexibility of the struts and the magnitude of the compressive pressure. The metal holders fortified many pillars and walls of ancient buildings, including the central pillar of the Faceted Chamber of the Moscow Kremlin and the pillars in the premises of the so-called Own half of the Grand Kremlin Palace.

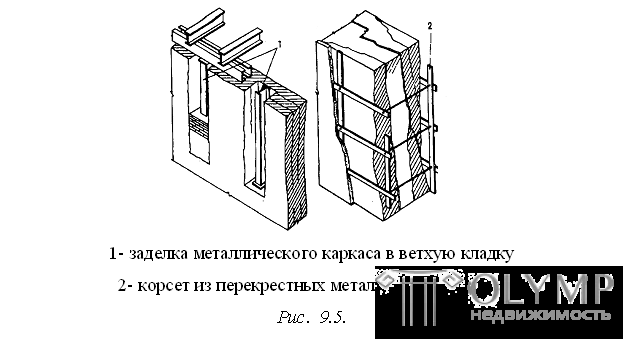

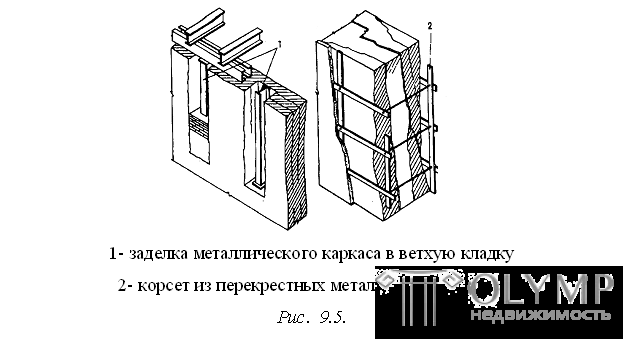

To reinforce wide walls, double-sided corsets are sometimes used in the form of flat welded gratings connected to reinforcing bars through holes drilled in the masonry. In a similar way, the weak and overloaded walls of the old Moscow Art Theater building were fixed (restoration of the 1980s). Metal corsets are usually masked in specially punched stubs or inside a thick plaster layer, which creates considerable difficulties in strengthening the pillars and pylons of a complex profile, bearing stucco or painting decor.

In the practice of restoration, it is not uncommon to replace an old building material with a more durable modern one.

This can be a simple external ligation and a through-lining with reinforcement of the danger zone. For example, an emergency sagging pillar of the porch of the Trinity Church in Nikitniki (Moscow) was disassembled and moved along with the foundation (with temporary complex “hanging out” of the above structures).

Sometimes the old masonry is preserved fragmentary or only as a facing layer hiding a metal or reinforced concrete bearing embedded in the structure body (Fig. 9.5). The installation of a modern bearing frame in a dilapidated or overloaded brickwork is a rather complicated task, connected with the need for deep stubbing, the introduction of a unloading element, temporary fastening, etc. In addition, a complete transfer of the load to the new design must be ensured, since the inclusion of heterogeneous materials in the joint proportional operation is practically impracticable due to the different deformation modules.

Metal racks are often used also for strengthening or unloading of wooden buildings of frame type and log cabins.

Reinforcement during structural failure of masonry. Structural destruction here means, firstly, the destruction of the building material of masonry elements, and secondly, the violation of the solidity of the masonry structure of entire structures. Structural destruction is subjected to overloaded, as well as wet laying (with leakage of roofs and utilities, capillary suction of moisture from the soil, corrosion of the embedded metal, changes in temperature and humidity conditions).

Characteristic signs of structural damage during overloads are the formation of a system of X-shaped cracks, puncturing of triangular prisms and depletion of compressed sections, sometimes vertically oriented cracks, delamination or undulating curvature of surfaces.

Frost and salt damage during soaking can be expressed in softening and spilling out the solution from the seams in the surface layer, peeling and falling of whole layers of masonry, the formation of loose, crumbling macadam conglomerate.

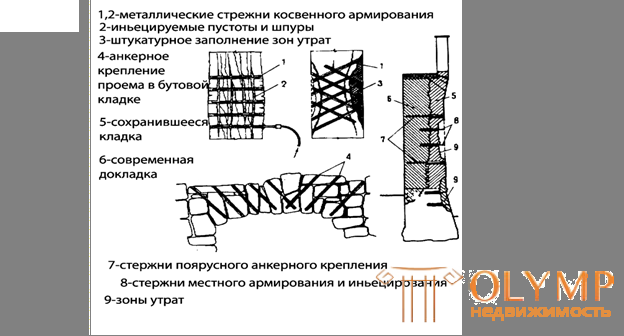

These types of damage create the need to develop so-called technological or combined methods of strengthening, for example, reinforcement and masonry injection (Fig. 9.6.)

Fig. 9.6. - Injection and combined masonry reinforcement

Layered brick structures can be reinforced with a system of anchor rods installed in the drilled holes normally or at a certain angle to the plane of the bundle. At the first stage, the rods work as anti-accident elements that prevent further stratification and reduce the free length of each layer as an independent compressible structure. In the second stage, when injecting gaps between the layers, the anchor rods perceive the overpressure of the solution created by the pump and which can cause the outer layer to collapse. Further, after the solution hardens and the layers are bonded, the rods serve as reinforcement elements.

Often located intersecting rods of "indirect" reinforcement reinforce the overloaded emergency structures of a small section - pillars, buttresses, and arch-butane. For massive walls of large stretch, having one or two open side surfaces, only transverse reinforcement is possible. Tiered arrangement of rods, the ends of which can be combined with reinforcing nets, is convenient for creating “supporting” reinforced rows or reinforced concrete belts when restoring a lost facial masonry.

Anchoring and other combined methods require a high production culture. Stainless steel is recommended for reinforcement, the amount of ferrous metal should be minimal even with its anti-corrosion coating. Corrosion of the embedded metal in wet masonry can lead to its ruptures and delaminations, pulling out a stretched rod or anchor, shear and collapse of masonry blocks. Practice shows that in the conditions of poor-quality work, anchoring or reinforcement of particularly important structures should be considered only as part of a fortifying complex, but not as the main or only type of reinforcement.

Injecting with specially selected solutions is a modern and very rational way to strengthen brick, stone and mixed masonry, dissected by cracks into large and medium blocks or gravel fractions. The effectiveness of injection reinforcement depends on the structure of the masonry, the degree of its separation, the moisture and chemical composition of the material, the quality of the solution, the frequency of the wells and other factors. The best results are usually achieved by injecting a comparatively dry, exfoliated masonry of brick, white stone, sandstone and tuff when cracking more than 1 mm. The hollow masonry from granite, basalt and other heavy non-porous materials is reinforced poorly by injection, since there is no water withdrawal, and the solution filling the seams remains loose, weakly adhering the fractured blocks and individual stones.

In general, the solidified injection solution must be close in its physical and technical properties to the masonry material. Components of the solutions can be lime-dough, cement, quartz dust, white stone flour, and cemyanka. For the injection of solutions used manual or mechanical pumps that create pressure up to 6-8 atm.

Injection is undesirable for strengthening the masonry of walls and arches with tempera or oil painting, as the water withdrawal from the solution is accompanied by the movement of salts destroying the soil and the painting layer.

Strengthening flexible and inclined racks and walls.

Externally unstable structures requiring the introduction of open, logically completing the working scheme of the reinforcement elements include inclined fortress and retaining walls, as well as enclosing walls and pillars of buildings with collapsed or disassembled interfloor overlappings. If the restoration of these overlaps is difficult or not justified methodically, then the excessive free length of the walls and columns can be reduced with the help of rod ties-puffs and struts, combining the elements into spatial blocks (Fig. 9.7).

Separate flexible walls in the absence of close stiffness modules (staircases, corner mates of walls, etc.) can be strengthened by open struts of tubular and other sections, lattice diaphragms, and also buttresses. Buttresses - a fairly common way to strengthen the restoration.

Depending on the architectural requirements and the nature of the load, they are made either from traditional materials - brick and stone, or from reinforced concrete. The effective operation of the buttress is possible only with the proper stability of its base. Practice proves that many historical buttresses, erected both before and after the onset of deformations, do not fulfill their functions, existing independently of the object being strengthened. When reinforcing retaining walls, it is possible to use reverse buttresses, as well as brown injection piles in combination with distribution pickups, caulking and masonry injection.

Fig. 9.7. - Strengthening unstable structures

Straightening walls, pillars, pilo new. If the slope of the walls, pylons, towers, etc. quite noticeable, and strengthening with the help of open structures is not possible, for example, for aesthetic reasons, there is a need to lift them (turn).

The simplest way is to straighten out detached continuous structures or compact rigid volumes — obelisks, pedestals, pylons, low decorative turrets, serf teeth, and console walls, the mass of which does not exceed 10-15 tons. In this case, the lifting can be done with light screw and hydraulic jacks with minimal labor costs.

A temporary holder of metal profiles (reinforced concrete) cuts into the base of the straightened structure, serving either directly above the jack-bar or focusing with lever application of forces (straightening the gravestone of Ahmet Yasavi in Turkestan). The bottom stop of the jack can be foundation laying or a specially reinforced slab. To lift the inclined drums of the Cathedral of the Annunciation of the Nizhny Novgorod monastery, reinforced concrete belts of the corset cathedral were used as the bottom stop of the jack. If not all the structure is straightened out, but some part of it or a tier, then the jack's effort is spent not only on raising this part, but also on the “rupture” of the structure, that is, on overcoming the adhesion forces of the solution. Therefore, in the area of the intended rupture, masonry stitch is made or the joint is cleared.

Relatively high pillars, and also, through-cracked or dissected structures, are straightened using safety fasteners of delays, traverses, frames, etc. The force of the jacks with inclined log or metal stops is transmitted to the vertical distribution element or into the yoke of one of the upper mounting levels.

Straightening belfries, minarets, and towers, that is, buildings with a very high center of gravity, is a complex task that requires a phased calculation of stability and the development of a system of interrelated lifting and holding devices. Since the length of the pushing stops is limited by their maximum flexibility, weight and angle of inclination (not more than 45 °), straightening of high-rise structures is carried out by tensioning cable systems.

There are straightening methods that are not based on lifting, but on lowering the structure with jacks, sandbags, combustible sleeper cages laid in special fines and openings on the side opposite to the slope. Both during lifting and lowering, the intermediate position of the structure is fixed with temporary gaskets and controlled by a plumb line system. When the design position is reached, the penalties are laid, the seams are caulked and injected.

A special kind of difficulty arises when straightening long, wavy-inclined walls, for example, fortifications, or fragments of deformed buildings. The principle of lifting or lowering remains, however, it becomes necessary to artificially divide the structure into blocks — with vertical sawing and horizontal walling. The rise of serfs of the multimeter thickness and the walls of the so-called half-block masonry requires double-sided or through-mounting, as it can be accompanied by the separation of masonry and bulging of the face layer.

Strengthening of wooden structures. The main type of core system gain is trusses, trusses and finishing structures - partial or complete replacement of their damaged elements. The method of replacement and docking depends on the nature of the rod operation in the system. Compressed elements - the upper belts of the trusses and the struts are joined and put into operation with the help of frontal and angular cuts, secured with clamps and studs.

Most responsible for the compressed parts of the trusses are the support node. With its loose connection, allowing play, there is a "spreading" of the contour of the upper belt. Respectively overlapping structures or tightening suspended to it are lowered accordingly. The sag of the lower belt is the greater, the sharper the angle of inclination of the upper, for example, when the upper belts of the farms of the Moscow Manege are inclined, 18 ° sags of puffs and the ceiling is 40-60 cm.

Replacing stretched elements — hangers and lower trusses of trusses — is more difficult, since with any method of joining, the material of the joined structures works in an unprofitable mode of spallation or lateral crushing of the fibers. Usually the joint of the lower belts is carried out with the help of side wooden or metal plates, tightened with bolts. Sometimes with small tensile forces, the old method of joining is used - the so-called “Dutch tooth”.

A short insert in the belts of trusses, rafters, and also in floor beams is usually called a prosthesis. Prosthetics of bent elements, for example, the ends of long ceiling beams, require high strength of work, the use of carefully fitted collars and rods. Usually, unique continuous truss belts and beams or ceiling structures that carry valuable stucco décor and have acoustic value (floor structures of the Moscow Conservatory) are usually prosthetic.

If for any reason the prosthetics of the elements and the tightening of the nodes do not provide the bearing capacity of the structure (or the proper geometry of the overlap), trusses and rafters are either reinforced with additional rods, or duplicated by modern structures. The partial duplication includes, for example, the construction of metal puffs, unloading the lower belts of the trusses and the spacing finishing systems, the racks and the runs of the metal half-timbered houses in the frame wooden buildings. With full duplication, all elements of historical constructions, which mainly play an expositional role, are unloaded. A proportional and controlled separation of functions between redundant and basic elements, such as steel and wooden floor beams, is unrealistic both because of the different stiffness characteristics of the materials and because of the difficulty in transferring the load.

In addition to solving methodological problems, as well as issues of statics and design of assemblies from dissimilar materials, the strengthening and preservation of wooden structures also implies the provision of optimum temperature and humidity conditions, ventilation and fire protection. Timber that replaces destroyed elements should be conditioned and in no case serve as a stimulator of the spread of fungus and beetles.

Strengthening and conservation of log cabins. Strengthening of massive wooden structures in the form of simple and complex log cabins, bridges, ryazhey, etc. consists mainly of the bulkheads of the walls, basements, and reels. Selective replacement of rotted rims is made with local “unclamping” of a log house with wedges or jacks. When replacing several whole crowns, corners and bearing walls in succession, the upstream part of the log house, along with the overlap structure, is pre-hung. The most difficult to strengthen high log cabins - towers, churches, mills.

It should be noted that the introduction of fresh logs in heavily deformed (skewed and failed) log houses has little effect on their stability. Moreover, new elements that are not connected into an independent framework may turn out to be alien rigid inclusions in the plastic structure of the old log house, concentrating the loads and stresses. Corner joints when drying new (raw) wood diverge, and, the larger the diameter of the rims and their humidity, the greater the gap on the cuttings. Loose and empty corner mates can cause a whole wall to fall out or the entire log house to collapse under the influence of wind and any other lateral load.

Among the ways to preserve log cabins there is a complete bulkhead with preliminary numbering of the rims and the subsequent special processing of wood, for example, impregnation in vacuum chambers.Untreated, disassembled material, remaining on the site or in a stack, can quickly lose its condition - shrink, rot, or destruct due to a change in the environment of existence. Newly assembled old or, especially, new untreated wood houses often change their geometry so much that their carpentry and decorative elements - doors, windows, etc., are completely unsuitable, not “fitting” into their openings and places.

Что бы оставить комментарий войдите

Комментарии (0)