For the insulation of reinforced concrete floor slabs (including monolithic) one of two completely different technologies can be used. Both of them allow their own implementation. This article contains a complete description of these technologies.

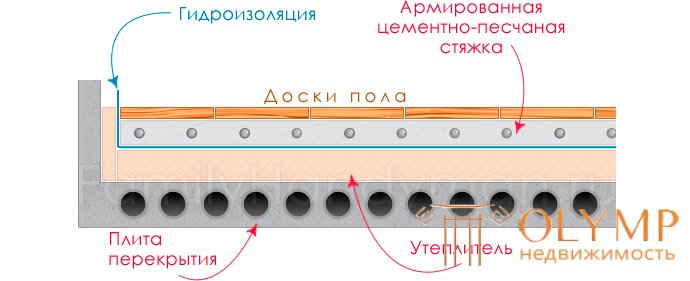

In the first variant of the reinforcement of reinforced concrete (concrete, reinforced) floors of the house, a concrete screed is arranged on top of the insulation plates laid on the ceiling.

Work begins with a search for existing seams and their subsequent incorporation with a cement-sand mortar. In the next stage, the entire overlap area is covered with insulating plates. The thickness of the insulation is determined by thermal calculations.

If a mineral-based material is used as insulation (similar to mineral wool), before laying it, the overlap is covered with a vapor-waterproofing film. The use of such insulation as EPPS - extruded polystyrene foam (which is not afraid of water) allows its device directly to the concrete base.

If the thickness of the insulation plates is not sufficient to achieve the planned height, then the laying of the insulation can be done in two layers.

On top of the heat-insulating layer is cement-sand screed. It must be reinforced, because the material with insufficient strength characteristics is used as the base - they are also heat insulating plates.

The coupler is leveled using a special leveling device. Such a base can be covered with any of the currently existing flooring: parquet, laminate, ceramic tile, carpet.

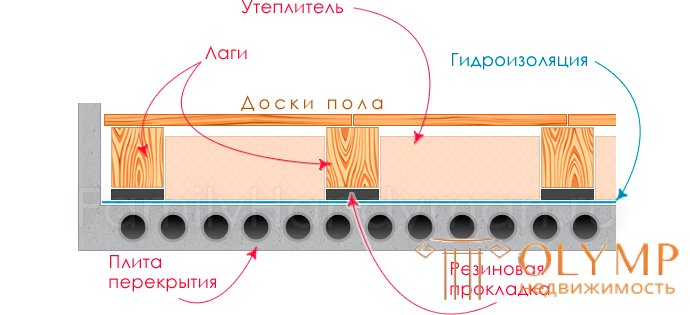

In the second variant, the floor slabs are insulated through the device of wooden flooring along the logs. Insulation is placed between the lags. Under the lags, on the reinforced concrete base, for the purpose of sound insulation put rubber pads. Top mounted wooden flooring.

Materials used for thermal insulation of floors are most susceptible to stress. In this regard, it is recommended to use materials with higher strength and small deformation under compression. These materials primarily include mineral wool and extruded polystyrene foam.

For insulating floors can be used, including unconventional materials, such as polyurethane foam and cellulose insulation. When such a device is blown onto a heat-insulated base under high pressure. Their advantage is the possibility of penetration into the smallest cavities. This creates a seamless thermal insulation.

Что бы оставить комментарий войдите

Комментарии (0)