When laying concrete mixes, different types of vibrators are used to get rid of air inclusions, to evenly distribute them over the area or shape. The role of this device is the simultaneous compaction and alignment of structures with a small depth of the concrete layer and a large surface area. Often made vibrating rail for concrete with his own hands, it helps to reduce the budget of construction works.

The effectiveness of this device can be fully felt only over large areas.

The high efficiency of this tool with a relatively small investment of energy and labor costs make it indispensable for the device:

Note!

Elements made using a manual vibrator, have increased strength and durability, rather than being built without a specialized tool.

Work with a vibrolath has a number of features that favorably distinguish it from other type of vibration equipment:

Despite the simplicity of this equipment, the screeds have several modifications:

The floating design of this tool is installed directly on the concrete surface and, accomplishing its own smooth progress, fulfills its mission. Such vibrolaths for laying concrete are used to compact mixtures to a depth not exceeding 18 centimeters.

Control of the floating equipment is carried out by one person due to the ease of the device and ease of operation. The most effective floating rail for the device smooth self-leveling floor.

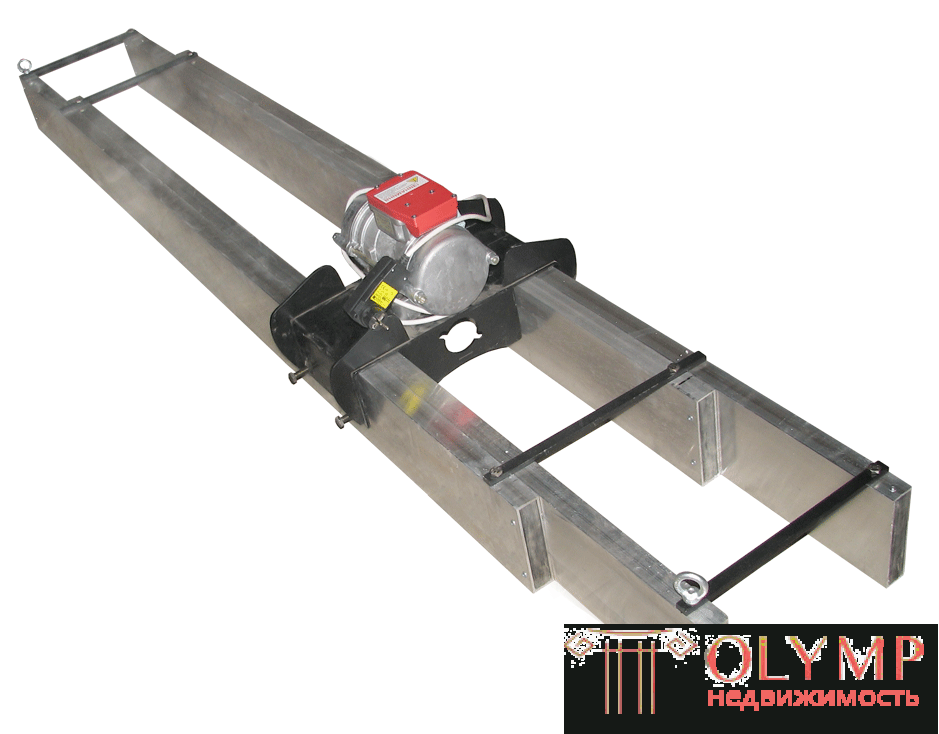

Vibrorail with existing guides copes with concrete with a layer thickness of 300 mm. High performance of this equipment is provided by equipping it with special guides of the required length and suitable configuration.

In the photo - the movement of equipment according to pre-set "limiters"

Guides allow the vibrating rail to hold onto the concrete surface. The power of such a tool allows to compact a solution of a specified thickness without involving submersible devices.

Interesting!

Quite often, the simplest equipment is made of suitable scrap metal: shaped pipes, angular steel, channel bars.

Equipped with such a device the simplest drive to create vibration.

To make the vibrating rail itself requires not only a piece of iron, but also the knowledge of connecting electrical devices

From the mechanisms operating along the guides, reversing devices are distinguished by a separate class. Due to its design with rounded edges, these vibrators operate when moving in the forward and reverse direction, which allows to increase the efficiency of the workflow.

The guides are installed at a level that allows you to avoid irregularities filled base

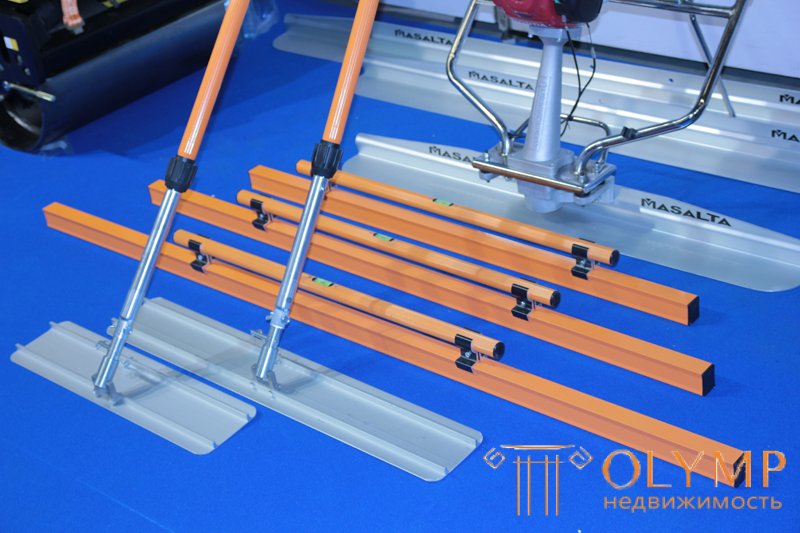

Separately, it should be noted the so-called sliding slats, which are made of aluminum or steel components.

Such telescopic structures allow you to adjust the working "capture":

Plus aluminum construction - lightness

Using such universal equipment, you can level the concrete floors, both in a large hangar and on a small platform, by setting the guides and dimensions of the mechanism in the required parameters. Vibrorail in this case performs compaction, and the alignment of the concrete mix at once over the entire area, and tightened along the treated surface with a cable.

The following type of hand-held vibrator reaches its maximum pickup length:

For the convenience of moving the device along the treated area, they are additionally equipped with hydraulic winches and a stop valve when there are possible obstacles to further advancement of the mechanism.

Note!

Cutting reinforced concrete with diamond circles also has some peculiarities in its working process.

After all, the denser the concrete, the less its structure is endowed with air, the more durable it will be, respectively, the effort and tools to work with it need more reliable.

Often, only diamond drilling of holes in concrete, which was made using the above tool, is available.

Instructions for working with vibrolath is quite simple:

Tip!

For single use, it is better to rent a vibrating rail.

The cost of renting does not significantly affect the cost of construction, but the price of the new mechanism does not pay off on a small amount of work.

Often in newspaper ads there are owners of home-made devices that are ready for a small fee to provide you with their own vibrolath.

As you can see, this manual tool is multifaceted and you need to clearly understand what work you want to carry out and what type of equipment will be more effective in different cases.

Что бы оставить комментарий войдите

Комментарии (0)