Very often, when working with plasterboard, it is necessary to assemble a skeleton from a metal profile. Most of them have an idea of how drywall should be mounted, but very few people guess all the intricacies and nuances of securing the profiles to each other. There are various ways to do this, but a plasterboard metal cutter is the most convenient.

Content:

The panes can have a very different shape depending on the manufacturer.

Prosekatel is a device for fastening profiles to each other. On his account, many have ambiguous views. Most agree on his needs, the smaller part considers this method of fastening as very unreliable. We will understand the situation, showing what positive qualities the slider has for the profile.

Immediately I would like to dwell on the negative aspects. The last paragraph dealt with the quality tool, but not all of them. Cheap sneakers can make weak cuts that easily loosen, which leads to a weakening of the mount. Sometimes more sinful sifters also sin in this way. Therefore, before choosing a tool, you need to make sure that it makes the correct cuts. In this case, the money is not worth it.

Prosekateli, which can do the work with one hand, more expensive two-handed

Do not forget that the cutter is used to temporarily fix the profiles before the frame of them is sheathed with plasterboard. Some consider it as a means by which you can firmly secure the frame. This opinion is wrong.

The question of which prosekatel better for connecting profiles does not have a single answer. However, it is possible to designate the qualities that a tool must possess in order to be considered good enough for work. D and in general it is worthwhile to pay attention to how this device works.

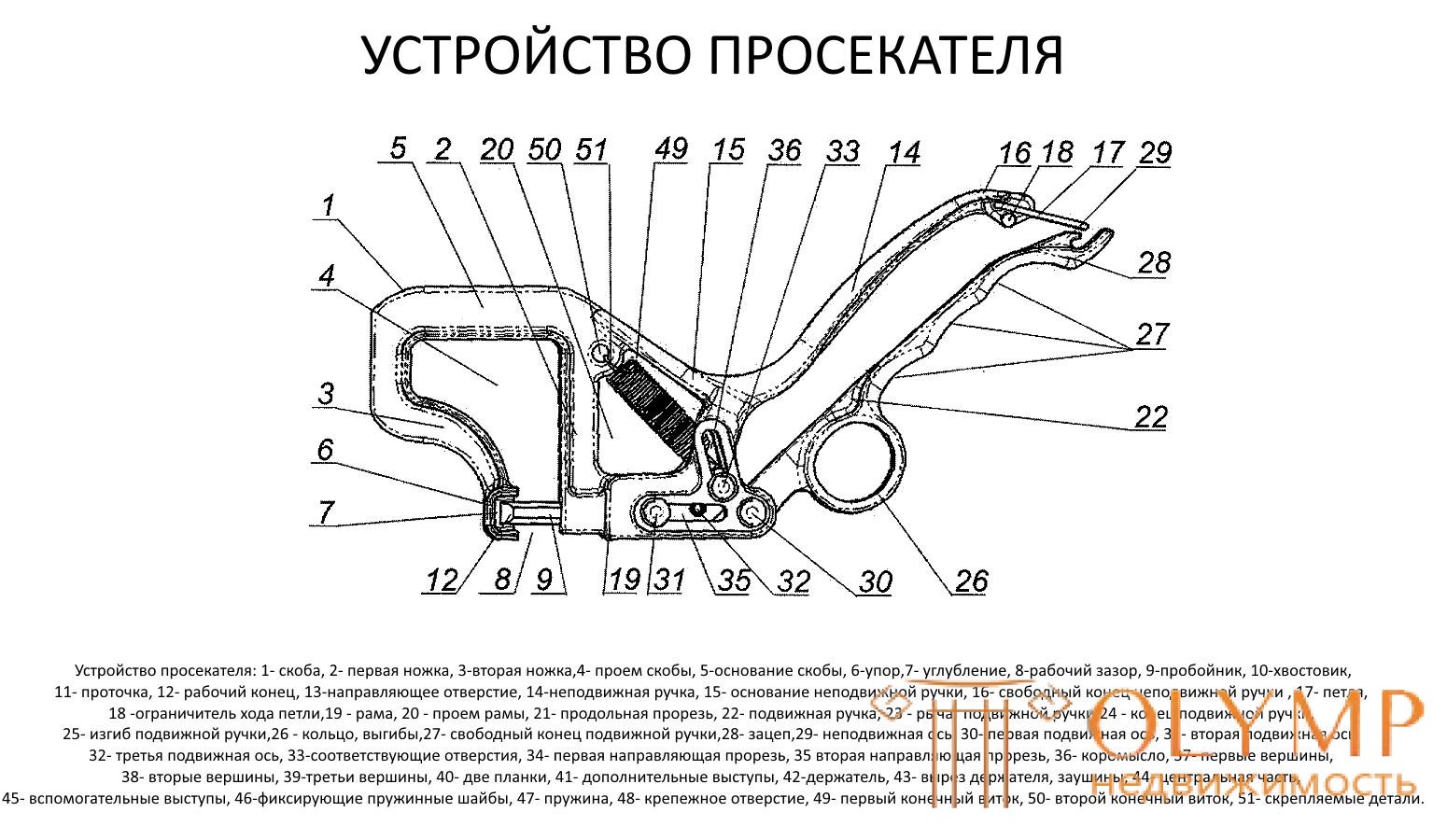

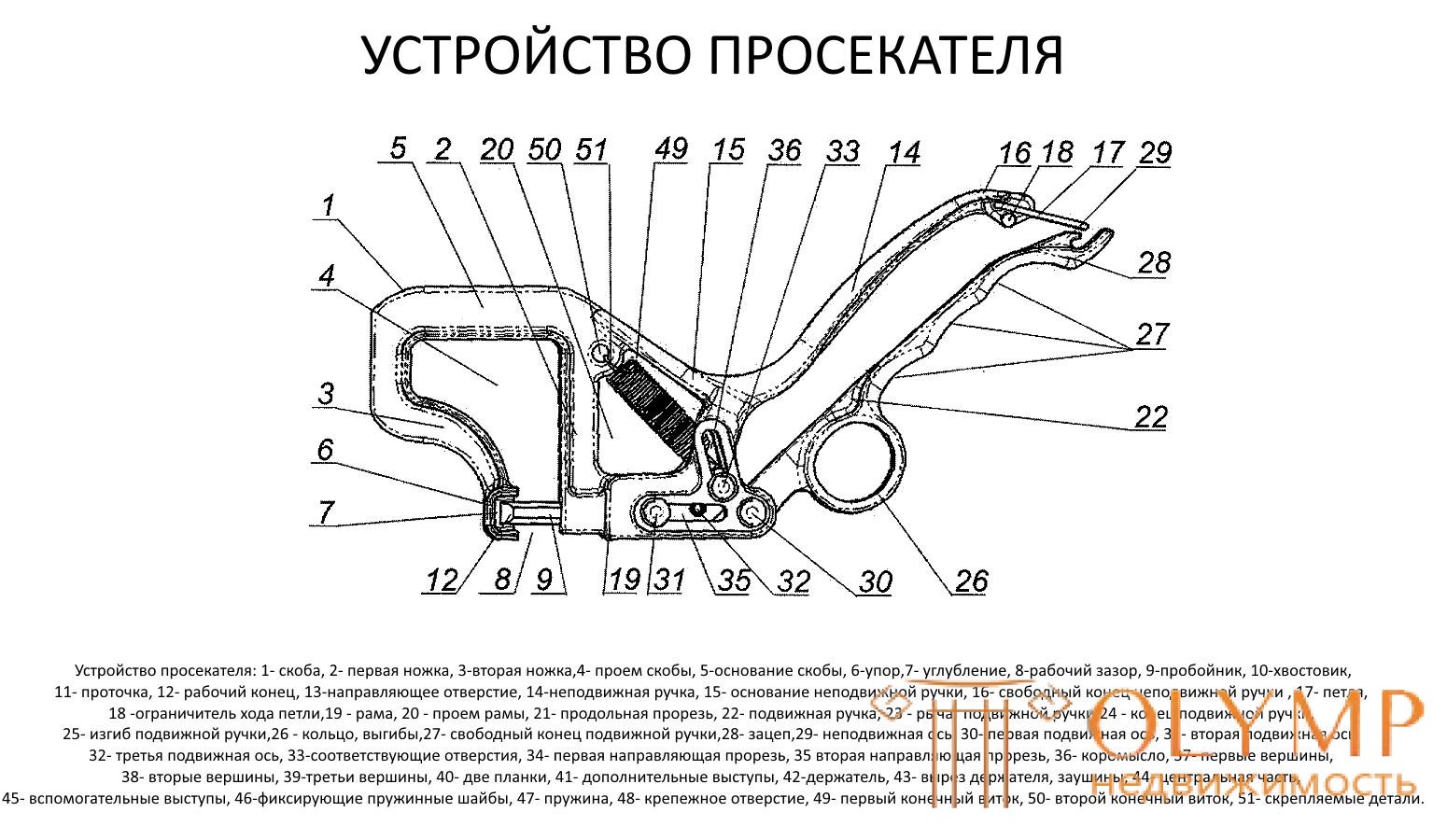

Detailed sifter device

10 years ago it was difficult to find a cutter that could be used to assemble a drywall frame. Now there are no such problems. In fact, there were so many cutters that it was difficult to make a choice. They come in different brands, models and types. By design, they are divided into the following types:

The simplest model of a prosekta no less qualitative than expensive analogs

At the prosekta the clip (ear) has to be rather big size. This is necessary so that the profile can enter into it and the tool is quite maneuverable. This is especially true when working with rack and guide profiles. Sometimes the bracket is so small that you can work comfortably only with the guides, but not with the ceiling profile.

When choosing a tool you should pay attention to the enhanced models. At their production strong materials are used, and the prosekatel practically cannot break during operation. Its cutting part can always be replaced if blunt.

To choose a cutter for the drywall profile, you need to focus on several indicators. But in the end it starts to seem like they all look the same. Even after filtering out unsuitable tools and picking up a hand-held cutter from good metal with a big ear and an ergonomic handle, questions remain. Under such criteria the weight of tools all the same approaches. And then you start thinking about the manufacturer.

The market leaders are companies that also manufacture drywall and profiles for it. Not surprisingly, many prefer Knauf products . Their model is very simple, but at the same time quite functional. The whole design of Knauf sifters consists of a fixed handle with a bracket, a movable handle and a piercer.

If you need a reinforced model, then choose the brand Stanley . The advantage of such cutters in their reliability and ability to work with one hand. But the price is higher than all competitors.

Prosekatel Knauf for fans, and Stanley - for professionals

If you want to save money, you can choose a Chinese Matrix or a domestic Centro Instrument . The price is small, the quality is appropriate.

The model of KB Prok is very convenient and easy to use, but it can only be used when creating partitions.

Knipex and EDMULTRAPROFIL products are made of thick steel . It is intended for professional use and costs accordingly.

There are many other brands whose products are not much different. Moreover, the price of such a tool can vary tenfold. If a cutter for a metal profile for drywall is needed for one repair, then you can take a cheap model that will be more difficult to work with. If it will be used often, it is better to take an expensive professional tool.

The order of work is very simple and even a child will cope with it if he has enough strength. For even greater accessibility we will make instructions on how to use step by step.

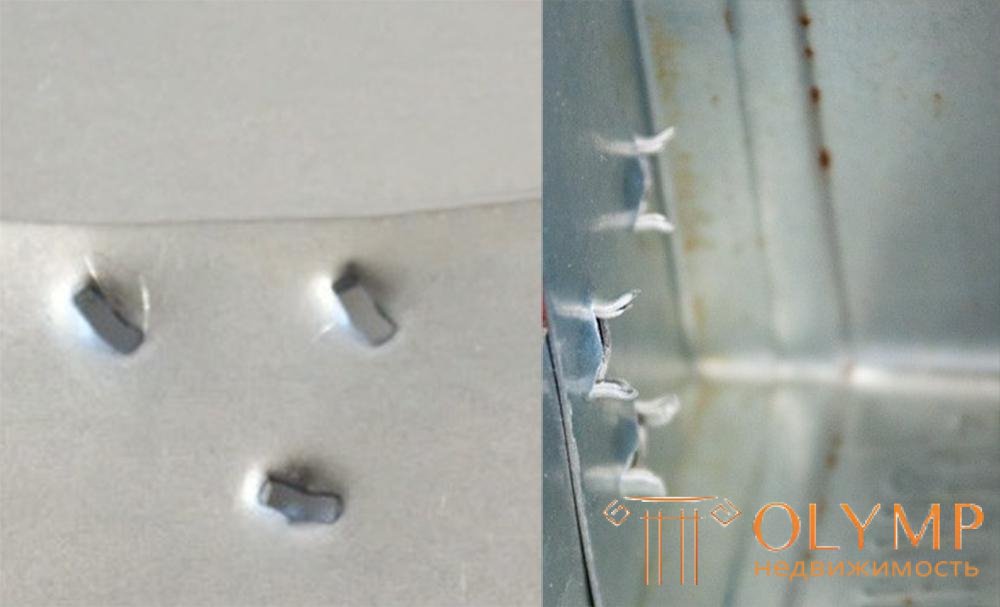

The resulting perforation may have a different shape, which depends on the model of the interceptor.

It is desirable to fasten each connection of profiles with two cuts, so it is more reliable. During operation, do not pull the tool in different directions. It must be in the same position during the fastening of the guides. During operation, the center of the punch should be placed at a right angle to the profiles that are held together.

The model should indicate the maximum size of the profile thickness with which it can work.

A number of requirements are put forward to professional cutters for a metal profile for drywall, as to how to care for them. However, for home repair with your own hands, all this is not relevant.

Что бы оставить комментарий войдите

Комментарии (0)