Cutting rod . The most favorable time for cutting the wicker lasts from the beginning of autumn leaf fall to the beginning of sap flow. In spring and summer cutting, the rod must be immediately cleaned of bark, because after 2-3 days the cambium dries out and the rod is poorly or even not cleaned at all.

|

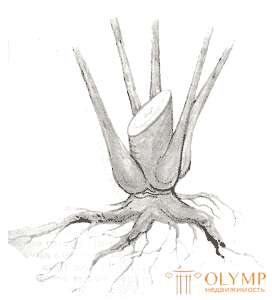

| The growth of shoots at low cutting bush |

The rod is cut with hand tools: pruners, garden knives, etc., and very sharp. The cut is made obliquely at a distance of 1-2 cm from the hemp and 3-4 cm in the spring and 3-4 cm for cutting. An ax cannot be used for cutting, since in this case the trunk and bark of the stump are destroyed, which causes it to rot and spoil the young shoots. The cut should be smooth, without scoring the bark and flakes of wood.

Sorting and storage . After cutting the rod sorted. Depending on their length and diameter in the butt cut, annual rods are divided into three categories: small (length 0.6–1 m, diameter 2–6 mm), medium (length 1.1–2 m, diameter 6.1–10 mm), large (2.1 m and more and 10.1-15 mm). The rod with a diameter of 15 mm and more is used on a furniture stick. Small rod is tied in 100 pieces, medium in 50, large in 25 pieces.

The green rod is stored in a dry, cool place or in the open air under a thick layer of snow. Moisture and severe frost are harmful to him: in a warm damp room, it becomes covered with mold and blackens, freezes in the cold. Usually the green rod is stored in trenches or pits covered with straw. It is perfectly preserved until spring.

It is recommended to store large batches of the rod on trellised platforms located 0.3-0.4 m above the ground. Tied bundles of willow twigs are laid by binding, i.e. each subsequent row is perpendicular to the previous one. To the top of the beams gradually bring together, forming a double-sided ramp. To protect the rod from drying out, the stack is covered on all sides with straw or straw mats, securing from above and from the sides with poles. The willow neogorenny rod laid in piles, best of all remains in the closed, blown rooms.

Bark removal . The technological process of manufacturing woven products begins with the cleaning of the rod from the bark. A peeled or, as it is also called, barked rod should be clean from the bark along the entire length, with a white shiny surface, should not have scratches, cracks and other mechanical damage. Whiteness, elasticity and flexibility of the rod depend on the method of its cleaning and drying, the conditions of storage and preparation for debarking.

Rod baring can be carried out practically throughout the whole year, depending on how the green bar is stored and prepared for cleaning. The most sturdy white bar is obtained by debarking cut sap flow, which in the central regions of Russia usually begins in late April - early May. Cutting the rod at this time does not weaken the strength of the bush and does not violate its livelihoods.

Sometimes it begins in early August and is carried out until the end of growth. During this period, the bark on the bars keeps weak, and they are well cleaned. The most favorable time for cutting plant rod life, as mentioned earlier, is autumn.

Rod, cut to sap flow, in the autumn-winter period, before debarking requires preliminary preparation. It is carried out in two ways: artificial recovery or heat treatment (boiling, steaming). During heat treatment, they never get such a white and beautiful rod, as when cleaning in the period of sap flow.

If the boiled or steamed rod sometimes gives a sufficiently white material, then it still becomes red or brown in color. Which one depends on what kind of tanning or dye from the bark penetrates the wood during the heat treatment.

Artificial revival of the rod (sap flow in it) can be caused by soaking in water. For this, dried ends are cut at the twigs, then they are not tightly tied into bunches and placed vertically in a container with water to a depth of 15-20 cm. The water temperature should not be lower than 14-16 ° С, that is, at which the growth of wood plants.

In winter, the rod is soaked in the room, and in summer - in the open air in pools with sandy bottom, in ditches and other bodies of water, where there is no fast current. Do not immerse the rod in water with a swampy, silty bottom, because it deteriorates: the wood in the water becomes covered with bluish spots, loses its flexibility and becomes brittle. Bundles of willow are immersed in water and tied to poles attached to racks hammered into the bottom of the reservoir.

Pre-rods are sorted by size, then bundles of long rods are immersed in deeper, shorter places - in shallow ones. All of them are installed so that they do not obscure each other, have free access of light, air and heat.

The duration of soaking is 13–20 days or more, depending on the willow variety, rod size, its initial humidity, water and air temperature. The first signs of the revival of the twig are the appearance of buds or even leaves on it and the easy separation of bark from wood. The readiness of the rod for debarking is determined by trial stripping of the bark.

Bars, harvested in autumn and winter and intended for cleaning after artificially induced sap flow, are immediately soaked in water or preserved by the method of freezing.

For freezing, freshly cut rods are placed in piles in layers with layers of snow 15–20 cm thick. Ready pads are covered with snow on all sides, and during frost they are poured with water until an ice crust forms.

The frozen shoulders are covered with leaves, straw, or, best of all, sawdust. An earthen roll-up thickness of 10–15 cm is arranged on top of the shelter. Freezing allows you to save willow raw materials during the whole spring-summer period until the next autumn bar is prepared. In this case, you can do without spring-summer blanks.

The willow raw material is thawed in a shaded place, with favorable warm weather, on the 10-12th day, sap flow begins, and the bark is easily separated from the wood. Rod, peeled after artificial revival, in its technical qualities is not worse than cut and peeled during sap flow.

The bars of the autumn and winter harvesting, not intended for artificial revival, are settled during the winter, before the onset of warm spring days, until it loses most of its moisture. Before debarking it is boiled or steamed. Special metal tanks and boilers are used for cooking, but sometimes wooden troughs in which water is heated using metal pipes.

The rod is boiled from 20 to 80 minutes, depending on its humidity and physical properties. With prolonged boiling, the bark is removed more easily, but the color of the twig is darker. To speed up and facilitate the removal of the bark, the rod after boiling is immersed in cold water. The rod is cleaned of bark in a warm condition, if necessary, it is heated on the lid of the welding tank. The water in the tank should be changed after 4-5 cooking. To get the rod less dark in color and speed up the cooking process, you can add 1.5-2% caustic soda to water; add more than 2% should not, because the rod becomes brittle. The degree of readiness of the rod is determined by trial stripping the bark.

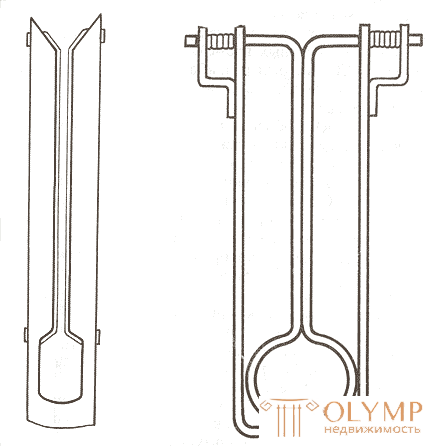

Steam rod is carried out in special chambers with airtight lids and pressure gauges. The camera is laid loosely tied into bunches of rods and allowed to steam. After 20-30 minutes, the steam supply is stopped, the rods are removed and immersed in cold water. The wetter the rod, the steaming takes place faster, so before barking it is useful to soak it in water for 1–4 hours. Peeled after steaming rods are lighter and cleaner than boiled. But in their qualities they are significantly inferior to the rod cleaned during the sap flow.

Removing the bark . To remove the bark from the twigs cut during the sap flow, no additional measures are required. It is enough to slightly break the adhesion of the bark to the stem of the rod with a special clamp, and the bark is easily separated. With his left hand they hold a scrambler, the end of which is stuck into the ground or into the hole of a bench, a board. Putting the rod into the scrambler, slightly squeeze it and, pulling, peel off the bark. If necessary, this operation is repeated.

Do not squeeze the scrambler very much, as it can crush the rod or make cuts or scratches on it. The rod prepared after the cessation of sap flow can be artificially revived. To do this, put the rod komlem in the water to a depth of 10-15 cm. Water should be running or change frequently. At the onset of a favorable thermal regime, the wicker starts to grow, i.e., sap flow begins, and the bark can be easily separated from the stem in the manner described above. Artificial revival can still be carried out throughout the winter in warm basements, setting the vine with komlami in wet sand.

The willow rod is most effectively artificially revitalized in heated greenhouses at a temperature of 14–16 ° C, where there is water and a translucent roof with a slope to the south or southeast. Flow under these conditions occurs in 12-14 days.

The wicker wood, sanded after artificial revival, has a natural white color and retains all of its mechanical properties. After debarking, the wicker is laid out in a thin layer to dry on special trellised floorings or placed vertically near the crossbars of poles.

In summer, this process is performed in the sun. In rainy weather, the rod is dried under a canopy, as from prolonged exposure to precipitation, it becomes stained, moldy and loses its presentation and mechanical properties. To remove the bark from the twigs special preparations are required. It is enough to slightly break the adhesion of the bark to the stem of the rod with the help of a shchemilki.

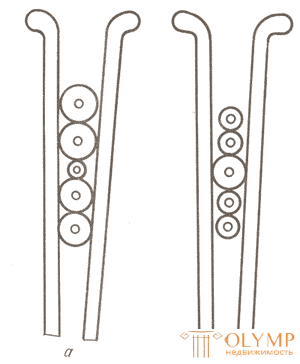

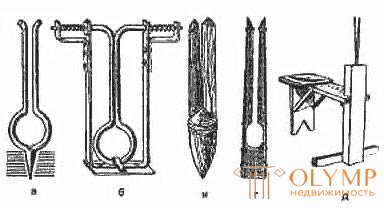

Scrapes are metal and wood. Metal shchemilki 35-50 cm long with a round or oval hole and an emphasis at the bottom is made of iron 10-15 mm wire. For the manufacture of wooden strands suitable for hardwood wood species. The 3-4 cm thick branch is cut straight and correctly split or sawed into 4 parts for 30–35 cm. Below the splitting stick is wrapped with wire, its other end is planed. Two opposite parts of the cleft are cut out, and between the remaining two they make a small gap.

|  |

| Scissors on the site of cutting rod | Wrong selection of rods according to the diameter when pulling through the scissors |

|  |

| The simplest design of shchemilok: a - for bar rod, b - for barking rod | Scissors for hardwood; Spring drill |

|  |

| Scissors with a seat | Scissors for debarking a wicker: a, b - metal; in - wooden; d - from an ash tree, lined with wire; d - used in the Ivanteevsky forest selection experimental indicative nursery |

There may be other varieties of wood curlers. In particular, thick twigs are rounded with a cheek made of ash wood and wire laid inside.

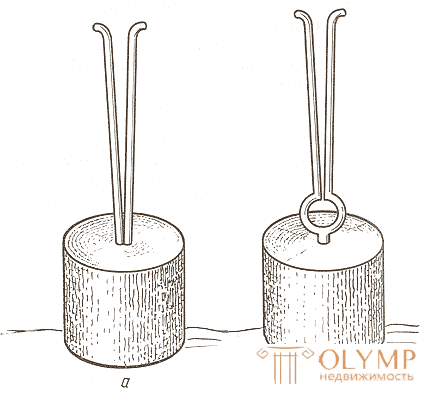

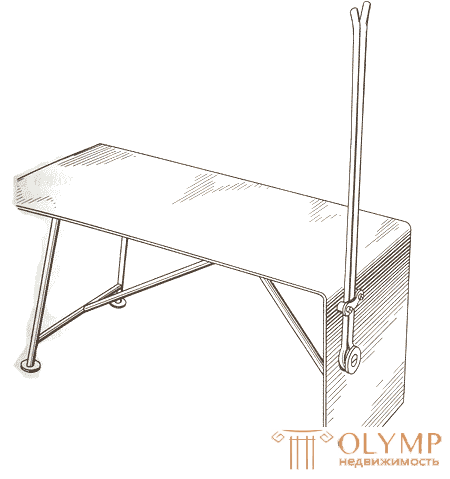

Scramblers strengthened in the ground or in a wooden block lying on the floor, it has a hole that serves as a nest for the lower end of the scrambler, which holds it in an upright position.

Many other types of scissors have been developed, but there is no particular need to describe them. The principle of their operation is similar, the only difference is in the design and fastening of the clamps. They make a variety of methods of labor for bar twisting, but this does not make labor itself less difficult and more attractive. This is the most difficult and time-consuming work in the production process of manufacturing woven products.

Sorting and drying . Peeled bark rod sorted by size and quality. If for any reason it is not possible to sort the rod immediately after debarking, it is dried. Immediate drying is necessary to preserve the luster and prevent stained darkening and the development of rot on it.

In the summer it is recommended to dry the rod in the open air, first in the shade to avoid cracking and warping, and then in the sun. From the sun the wood of the rod is bleached.

To dry the rod laid out on the floor of the boards or poles, in the process of drying it periodically overturned. If this is not done, one side of the rod will be lighter than the other. The rod is dried in good, clear weather, because of the long rains it darkens, becomes covered with mold and stains.

In rainy weather, the rod is dried under a canopy. Dried under a canopy or in other closed (even ventilated) premises, the rod does not have that beautiful white color that it gets when dried in the sun. In this regard, you need to use every fine day. To dry the rod should be as long as the moisture content in it will be no more than 12-15%. Do not overdry the rod, it becomes fragile, making it difficult to further processing. It takes 2-3 days to dry the rod in the spring or summer in the sun; in rainy times, it takes 5-6 days to dry under canopies. The dried rod is tied up in bunches and placed in the sun for another 2-3 days.

During the sorting it is necessary to disassemble the rod not only in size but also in quality. This means that you need to pay attention to the flaws of the rod (sbezhistost barrel, etc.) and its appearance. The sorted rod should be of a certain size, have a straight trunk, even, without mechanical damage, warts, wormholes and sukhobin, a surface free from bark, shiny, uniform color, sharp needle fiber when broken. It is completely unsuitable for weaving a rod that has a dull black color, a putrid odor, a deep spot that has lost its luster.

Whitening and dyeing . Yellowed, darkened or stained rods are whitened or used for weaving in a colored form. During the heat treatment of the green rod, the wood of certain species of willow is colored red-brown. Bleaching such rods should not be. Wicker products made from naturally colored rod have a pleasant, beautiful look and are greatly appreciated by customers. To obtain rods with intense color, it is necessary to boil the green rod up to 2 hours.

The easiest way to bleach is fumigating with sulfur in hermetically sealed boxes or chambers. Before bleaching the rod is moistened with water, freely laid out on a rack. For fumigation, take 60 g of sulfur per 1 m3 of the volume of the box (chamber). Sulfur is placed in a clay and metal vessel and lit. When it is well heated, the chamber is closed, all the gaps are sealed or covered with clay tightly. Bleaching lasts 3-6 hours.

Bleaching can be carried out with sulfuric acid vapor. The specially prepared solution contains 100 parts of water, 70 parts by weight of slaked lime and 2 parts of sulfuric acid. For bleaching take the solution at the rate of 1.2-1.8 liters per 1 m of the volume of the box (chamber). The dishes with the solvent are placed in the chamber, closed, the gaps are sealed or covered. The gases emitted from the liquid bleach the rod. This process lasts 1-2 days.

Finished products and materials for weaving are also bleached by soaking in a solution, which is prepared as follows: 1 part of bleach is mixed with 15 parts of water diluted with 1-2% sulfuric acid.

Dried and sorted rod tied in bunches. The bundle is tied up in two places: 25-30 cm from the butt and about half the length of the rods. In the butt part of the beam should not have a circle more than a meter. A bundle of twigs is stored piled in a dry, dark and well-ventilated area. The rod is laid on wooden planks and poles laid on the floor. In the piles for ventilation leave small voids. For this, the rows of beams are shifted with poles or placed on special floor boards. The upper and lower beams periodically change places so that the bars at the bottom do not rot.

With proper storage, the white rod does not lose its qualities and suitability for use within 4-5 years. To restore flexibility, before use, the rod is pre-soaked in special tanks or troughs in clean water at room temperature. Soaking is best done in several stages, since the rod turns black after a long stay in the water. Well soaked rod should be elastic, do not break during operation. The duration of soaking depends on the type of willow, the timing and storage conditions of the rod.

Что бы оставить комментарий войдите

Комментарии (0)