A truss is a lattice structural element consisting of individual rods connected in knots and working for the most part in bending. When loads are applied to the nodes in the truss rods, only compressive or decompression forces arise. The truss consists of belts and lattice rods. The distance between adjacent nodes of the belts is called the panel. The size of the panel depends on the size of the roof plates, the angle of the diagonal bars and the span of the truss. For type truss size of the panel adopted 3m, on the support h = 2.2m, incl. ce i = 1: 12 or i = 1: 8.

Farm span is taken as a multiple of ce.

Runs:

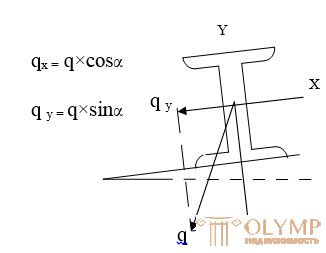

Sling. f. in a covering rast. in increments of 6 m or 12 m at the roof of small-sized plates, aluminum, steel or asbestos cement sheets, runs are used. At step farms 6m. girders are used from rolling, with a step of 12m - bar or rank. Runs are installed in the nodes v.p. if the farm has a slope, the run runs and is calculated for oblique bending.

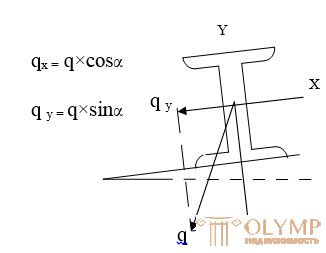

Vert. ... ... is disclosed to the lead axes of the girder, its value is determined and the bend is found, moments in two mutually perpendicular planes. Knowing the running vert. … .. and the inclination angle v. trusses, find qx and qy, voltage in the run:

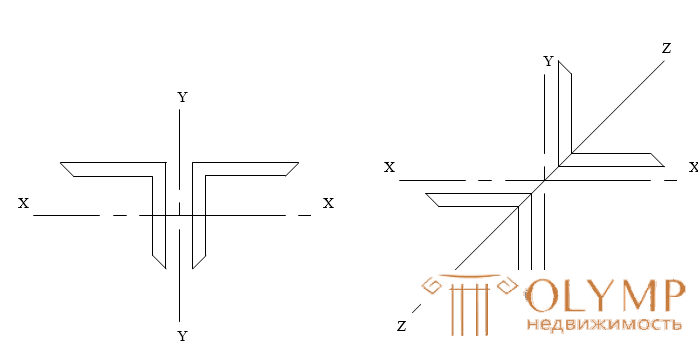

Links and their appointments:

Connections are designed to give the construction of spatial rigidity and immutability, as well as to ensure the sustainability of its elements (farms). In pokr. applying horizontal and vertical communications. Of particular importance are the links in the compressed belt farms, providing them with stability. Belts sling farm serve belt slings. farms, grating is usually used in the cross system.

In industrial buildings ties raskr. and n. farm belts.

Vertical connections are established in the plane of the supporting walls of the truss, as well as in the span by vertical and horizontal connections connecting two trusses into a spatial immutable block. The length of the communication shop set after 60m.

Collecting loads:

The following loads act on the farm: its own weight of the roof structures, all the roofs, in the presence of a suspended ceiling, all of it, temporary loads on the attic, and snow load. Sometimes on the farm m. transferred load from wind, rolling vehicles and equipment. All loads perceived by the farm d. attached to its nodes.

Having calculated the nodal load from its own weight of the structure and roof with the same size of truss panels, we will determine by the formula:

|

n = 1.1 - overload factor for its own weight of structures,

qnkr - the weight of the roof on 1m2 area.

α - the angle of inclination in the projection of the farm to the horizontal

d is the size of the panel.

B - step farms.

If there is a lantern, then its weight must also be included in the nodal load.

Рсн = n * Pно * с * d * B;

Where n = 1.4 is the overload factor for snow load.

Pno - snow cover weight per 1m2 horizontal surface

C - coefficient taken depending on the configuration of the roof.

Similarly, one should determine the concentration of forces from any other loads perceived by the trusses and fastening them in the nodes.

Having established the nodal load, go to the definition of effort in the rods of the farm.

4. SELECTION OF SEC. RODS of the TRAIL FARM.

GENERAL PROVISIONS:

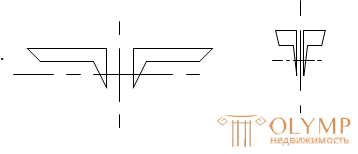

Truss bar sections can be designed in any shape. The most common Tavrovye, consisting of two corners.

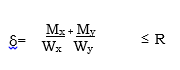

When selecting sections of truss rods, it is necessary to ensure that their flexibility does not exceed the limit of values; mouth in v.2.

|

|

|

LIMIT OF FLEXIBLE STEM FARM:

The cross section of the truss rods from two corners:

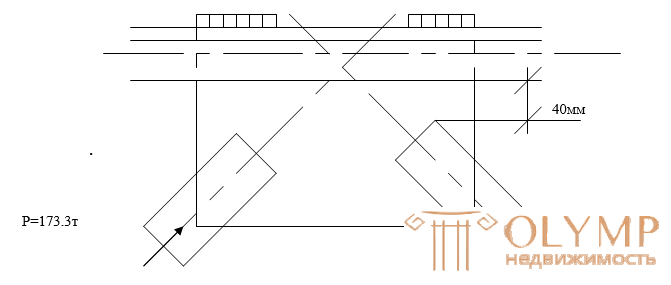

The thickness of the gouges is usually assumed to be the same in all the nodes of the truss and is taken according to the greatest calculated force in the support diagonal according to the table.

5. Determination of the estimated lengths of the truss rods.

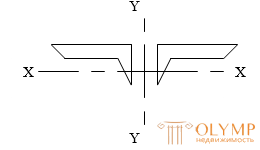

The calculated lengths for the belts are taken equal: in the plane of the truss ℓx = ℓ and from the plane ℓу = ℓ1, where ℓ is the distance between the centers of the nodes; ℓ1 is the distance between the fixed nodes from the silt. The fastening of the truss belts from its plane is achieved by connections, girders, slabs or roof shields.

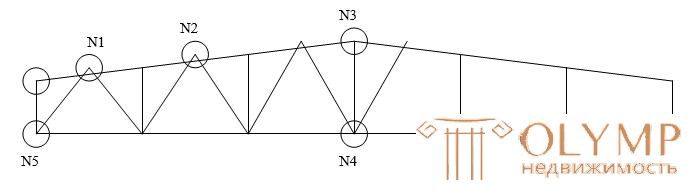

Farm Node Numbering.

The estimated lengths of the support braces and racks are = ℓx - ℓy = ℓ.

For intermediate braces and racks, the calculated lengths are assumed to be equal, in the plane of the truss, ℓ x = 0.8ℓ, from the mud. =y = ℓ.

Coefficient taking into account the partial pinching of the lattice rods with the gussets in the nodes of the lower stretched belt.

Starting the selection of the cross section of the belts you need to outline the places where the cross sections change. It is recommended for flight up to 24m inclusive to maintain a constant section along the entire length of the belt, selecting it for the greatest effort. Over 30m in order to save metal, the cross section of the belt is better to change. For the upper belt, it is possible to use both equilateral and non-equal angles.

Equal angles are recommended to apply when the opportunity to fix from the square. truss every knot belt and ℓx = y.

When attaching vp through the node, when ℓу = 2ℓx, it is advisable to use unequal angles connected by smaller angles together.

Pl. cross-section of the upper compressed belt:

Ftr = N / Y * R, where

N is the largest effort for the accepted site of a belt with constant section;

Y is the buckling coefficient, for which you need to be flexible, taking it in advance. = 80 ÷ 100.

With the efforts in the belts more than 150 ÷ 200t. It is recommended to use low-alloyed steels for belts and bearing braces, for Art. 3 lattice rods.

Having picked up a section of a squeezed belt, it is necessary to check its stability, adhering to the following order:

1) Determine the radii of inertia of the sections rх and rу;

2) Determine the flexibility λx and λY and for the most flexibility take φ .

3) Perform a stress test:

σ = N / φ F ≤ R , where

F-actual Il. adopted section. Ultimate flexibility for sys. belts

λ before = 120; at the time of installation λ before = 200.

Stability check syst. rods of trusses according to the formula ( φ production, provided that the corners (or other profiles) of the section are joined by welding closely or through gaskets.

In the latter case, the distance between the gaskets in the light is not made greater than > 40r, where r is the radius of inertia of the profile, relative to an axis parallel to the plane of the gasket. For tensioned rods, the marginal distance between the gaskets = 80r.

For the lower stretched and. it is recommended to apply the developed from silt. f. Sech., which improves the conditions of transportation and installation of farms.

The required cross-sectional area is determined by the formula:

FTP = N / R

σ = N / F nt ≤ R

7. SELECTION OF GRID GRILLES.

Section of compressed cross strut at осаx = ℓy. compose them of two non-equal angles at ℓу = 2ℓx, (if a cross-section strut is present, it should be taken) also from non-equal angles.

Selection of the section and stability check of the compressed brace should be performed in the same way as for the cef.

For stop compressed rods lattice Sich. of the two equally spaced corners is the most satisfying condition of equal stability.

Required Il sech. should be determined by the formula:

F Tr = N / m * φ * R

where m is the coefficient of the service. slave. We assume for the system of braces and racks, (except for the supporting ones) with λ≥60 equal to 0.8, with λ <60 = 1.

φ - prod. from., depending. from X, previously taken 80-130. (a smaller value should be taken for more heated and shorter rods).

Having picked up the section, check the stability according to the formula:

σ = N / m * φ * R ≤ R

Cross-section of braces adjacent to the middle of trapezoid. trusses, due to small efforts in them, are selected for maximum flexibility.

For brands. the cross section of two equally spaced angles with the minimum radius of inertia is rx = ℓx ⁄ λpre, where λ pre = 150.

According to the obtained value of rх, according to xxxxxxxxxxx, the smallest size of the angle is established.

For compressed racks, to which vertical links are adjacent, a cross-section of their two corners is convenient. Check the stability of the rod of the cross section is made about the axis. As min we take *50 * 5.

DESIGN SOLUTIONS AND CALCULATION OF FARM NODES:

1) General guidelines for seam calculations.

Rasch. defined the dimensions of the seams attaching the truss rods to the gussets or to each other. Occasionally, a test of the strength of the gussets is performed.

For attaching the truss rods to the gussets, it is recommended to use flanking seams with their output to the end of the corner (approximately 20 mm) or to use contour trimming.

Typically, the thickness of the seams xxxxxxxxxx are set, assigning it depending on the thickness of the welded elements and a multiple of 2 mm. According to the angle of the corner, the thickness of the seam should be taken at 1-2 mm <thickness of the corner shelf; on the edge xxx of the seams it is allowed to take not> 1.2 xxx, where xxx is the smaller thickness of the connection of elements (gusset or angle).

The weld xxx must not be <4mm; the length should not be <4mm hш and not <50mm.

The number of differences in thickness of the seams should not exceed 3-4 x for the entire truss.

The length of the flank seams is determined by:

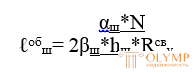

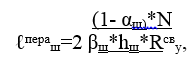

For feathers

where Lш - coefficient depending on the type of angle and its position in the section. For equal angles, Lш = 0.7, for non-equilateral, welded to the gusset by large shelves, Lш = 0.65 and smaller Lш = 0.75.

Βш - coefficient taken in manual welding = 0.7.

Rcвy - calc. resist fillet welds cut off.

The length of the seam is equal to the length of the grommets, installed. usually when designing a node, min the thickness is determined by the formulas:

where T is the shear force equal to the difference in the forces in the belts.

Lsh - the length of the seam in cm, equal to the length of the gusset, minus 10 mm.

In the nodes of the farm, which are only adjacent to the rack, belt seams should be counted on the force in the racks.

Что бы оставить комментарий войдите

Комментарии (0)