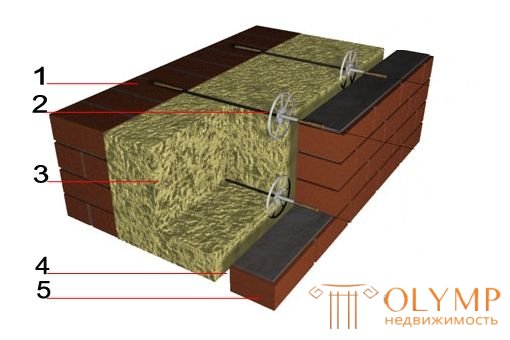

Composite flexible connections are used in construction to connect the inner wall with the facing layer through insulation in the system of three-layer walls (Figure 1.).

Figure 1. Layout of a three-layer wall:

1. The inner part of the wall;

2. Flexible communication;

3. Insulation;

4. air gap;

5. Facing part of the wall

The role of the flexible connection is to connect the inner wall through the insulation (and the air gap) with the facing wall into a single unit.

The bond is called “flexible” due to the structural characteristics of a three-layer wall. The inside of the wall is facing the inside of the room, and therefore its temperature and geometric dimensions are not subject to significant changes. The opposite situation occurs with the facing part: in the summer it can heat up to 70ºС and in the winter to cool to minus 40-50ºС. Due to temperature differences, its geometric dimensions change. Since the inner wall remains stationary and the facing “plays”, the flexible connection is subject to bending (hence the name “flexible connection”). Therefore, the strength of the joint of the walls and, consequently, the reliability of the entire construction object depends on the properties of the material from which it is made.

| |

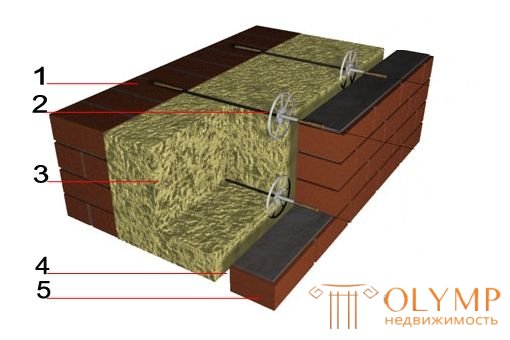

| Emergency situations: a - Collapse of the facade of the building due to corrosion of steel ties | b - condensation of moisture on the surface of the facing layer |

Figure 2.

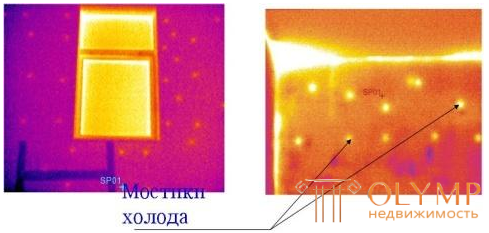

Figure 3. Thermal imaging of a fragment of a three-layer wall with flexible metal connections

According to SNiP II-22-81 "Stone and Arm-Stone Constructions", p. 6. 31: "Flexible connections should be designed from corrosion-resistant steels or steels protected from corrosion, as well as from polymeric materials." Composite materials are used as polymeric materials - these are basalt and fiberglass.

This SNiP indicates that the use of non-corrosion resistant fittings, ferrous metal fittings and wire as flexible connections is dangerous because their corrosion, leading to the collapse of facing walls, affects the safety of the building. This condition of the structure is emergency and living in this room is life threatening due to the real possibility of collapse (Figure 2). Repair of such an emergency building requires considerable time and material costs, which is unprofitable from an economic point of view.

Today in Russia there is an acute question about the energy efficiency of buildings and structures, therefore thermal conductivity is one of the main characteristics of flexible connections: the lower the value of thermal conductivity, the less flexible connection allows heat to pass and does not form so-called “cold bridges” - the location of the reinforcement in the wall through which heat loss occurs, condensate forms. Thermal imaging of a three-layer wall shows a large number of dark orange dots - “cold bridges” - locations of metallic flexible connections (Figure 3). It should be noted that when using flexible connections made of composite materials, “cold bridges” are not formed and there is a reduction in heat loss to 34%, which significantly reduces the cost of heating the building.

The technical characteristics of the materials from which flexible connections can be made are indicated in Table 1.

Table 1. Characteristics of materials of flexible connections.

| Indicators | Basalt plastic | Carbon steel | Fiberglass | Stainless steel |

|---|---|---|---|---|

| 1. Tensile strength, MPa | 1400 | 550 | 1000 | 550 |

| 2. Thermal conductivity | Less than 0.46 | 56 | Less than 1.0 | 17 |

| 3. Fire resistance, ° С | up to 600 | up to 600 | up to 150 | up to 600 |

| 4. Modulus of elasticity, GPa | 60 | 200 | 50 | 200 |

| 5. Electrical conductivity | does not conduct electricity | conducts electricity | Does not conduct electricity | Conducts electricity |

| 6. Magnetic characteristic | Not magnetized | Magnetized | Not magnetized | Not magnetized |

| 7. Density | 2.1 | 7.85 | 2.2 | 7.85 |

| 8. Reliability indicators | very high corrosion and chemical resistance | low corrosion and chemical resistance | high corrosion and chemical resistance | high corrosion and chemical resistance |

Figure 4 . Basaltoplastic flexible bond

Figure 5 . The calculation of the length of the flexible connection in the construction of a three-layer wall with an air gap

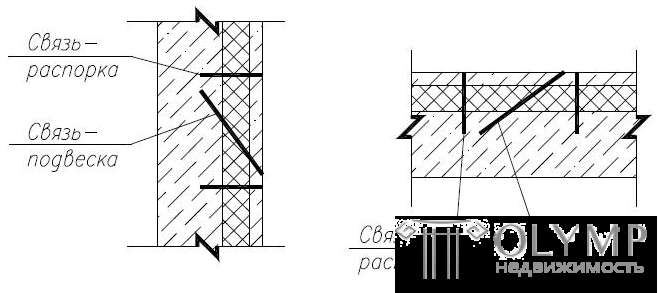

Figure 6 . Connection of concrete layers by suspensions, struts and struts

In the Russian Federation, fiberglass flexible connections are most common. They are a rod of circular cross section with thickening of sand at the ends, which act as an anchor (clutch) when fixing in the joints of the masonry. Sand anchors provide a strong bond with mortar and provide additional corrosion protection in the alkaline environment of concrete. To create an air gap, a clamp made of impact-resistant and frost-resistant material is used (Figure 4). The air gap creates conditions for natural ventilation of the facade.

When building a three-layer wall, use the following formula to calculate the length of the flexible connection (Figure 5):

L = 90 mm + T (+40 mm) + 90 mm , where

L is the length of the flexible connection;

90 mm - anchoring depth for flexible connection ends;

T is the thickness of the insulation;

40 mm are added when erecting a wall with an air gap.

Example: if the insulation thickness is 120 mm, then:

Flexible couplings are widely used in large-panel housing construction as spacers, struts and suspensions:

internal (Figure 6).

Thus, the energy efficiency and safety of the building, as well as the subsequent costs of its operation depend on the correct choice of the material from which the flexible connection is made.

Что бы оставить комментарий войдите

Комментарии (0)