Preparation of the farm for installation consists of the following operations: pre-assembly, arrangement of cradles, ladders and braces, slinging, lifting into the installation zone, turning with braces across the span, temporary fixation using conductors, braces, struts between the trusses and delays. The position of the truss is calibrated by the position of the axial scratches at the ends of the truss.

Depending on their mass and length of the farm, they are lifted with the help of traverses with one or two cranes. The slinging of the trusses is made only in the nodes of the upper belt so that bending forces do not occur in the rods; trusses sling at four points with cross-arms with semi-automatic remote control grippers. At high installation loads, temporary reinforcement of elements is effected with wooden plates or metal pipes. The first raised farm is unwrapped with the help of delays in the design position at a height of 0.5 ... 0.7 m above the top of the columns, lowered onto the mounting tables welded to the columns, temporarily fixed on the bolts, checked and carried out the final fastening. When lifting to avoid rocking, it is supported by four flexible braces.

After installing and securing the first truss and unfastening it with four stretch marks, they install the second one, which is connected to the first one with the help of runs, ties and struts, they all together form a rigid spatial system. On the columns of the middle rows, the farm is additionally bolted to the trusses near the mounted span.

In the case of building schemes with trusses and subrafter trusses, the latter have a length of 11.75 m and are installed on columns with gaps of 25 cm. In this gap, a headboard is installed on which the roof truss will be supported.

Coatings made of steel profiled flooring is used in buildings with a metal and reinforced concrete frame to facilitate its weight, as well as when installing coatings in large blocks. Wired panels of prefabricated flooring can be supplied for installation.

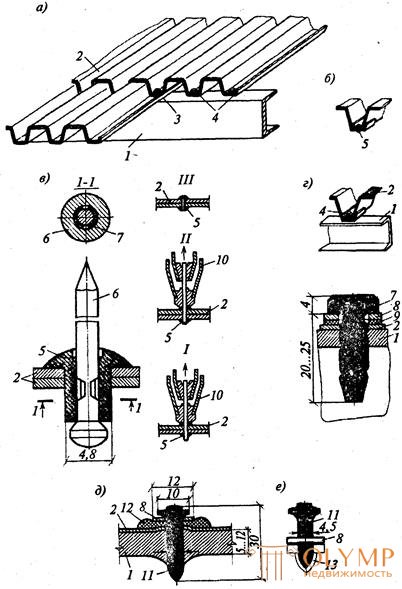

Steel profiled flooring is a galvanized panel, and then a steel sheet coated with an anti-corrosion layer, 3 ... 12 m long, 0.8 ... 1 mm thick, with longitudinal corrugations 60, 79 mm or more in height. The width of the sheets of flooring is 680 ... 845 mm, the length is a multiple of three - 6, 9 and 12 m and is appointed by the project in accordance with the location of the truss girders (Fig. 17.2).

Sheets are enlarged into cards on horizontal stands, equipped with stops aligned to the size of the cards, and joined together by combined rivets or resistance spot welding. After the sheets are laid out with a hand-held electric drill, holes are drilled for rivets at the joints of the sheets in a wave of overlap. The holes are drilled in accordance with the design, usually 50 ... 60 cm. The rivets are inserted into the drilled holes, thus joining the sheets into a single map of the desired size.

| Fig. 17.2. Steel profiled flooring: a - coverage scheme; b - joining of flooring sheets with a combined rivet; in - the sequence of installation of the rivet; d - fixing the flooring with a self-tapping screw; d - fixing the flooring with a dowel; e - dowel; 1 - steel pro-gon; 2 - flooring; 3 - connection of the flooring with a self-tapping screw at the joint; 4 - the same, in the gaps (slots) of us; 5 - aluminum alloy rivet; 6 - steel rod; 7 - self-adjusting screw; 8 - steel washer; 9 - sealing washer; 10 - tool for setting rivets; 11 - dowel; 12 - polyethylene gasket; 13 - polyethylene tip Coatings from profiled flooring is inadvisable to mount element-wise (sheet) |

way due to the large labor intensity - the entire amount of work has to be done at height. Often mounted cover maps of the above sizes. The assembled cards are mounted in the course of installation of the coating structures (following the installation of columns and crane girders). The stand on which the coverage maps are collected is rearranged, if necessary, by a crane to new parking areas.

The card is sling according to the slinging scheme and, depending on the size of the card, is lifted by a crane and fed to the place of installation. Flooring in the form of sheets or pre-enlarged maps of 6x6, 6x12, 12x12 m in size is placed on the roofing girders or covering blocks. Cover runs are installed on the truss nodes, and when using trusses from rectangular closed profiles, directly onto the upper truss belts. The position of the maps of the profiled flooring is customized according to the risks of marking the laying places.

The card is sling according to the slinging scheme and, depending on the size of the card, is lifted by a crane and fed to the place of installation. Flooring in the form of sheets or pre-enlarged maps of 6x6, 6x12, 12x12 m in size is placed on the roofing girders or covering blocks. Cover runs are installed on the truss nodes, and when using trusses from rectangular closed profiles, directly onto the upper truss belts. The position of the maps of the profiled flooring is customized according to the risks of marking the laying places.

Cards are attached to the runs with self-tapping galvanized screws, less often with dowels and electrical rivets. To fasten the floorings to the girder, they are pre-drilled through holes with a diameter of 5.5 mm using a power tool, then self-tapping screws with a diameter of 6 mm with a plastic or steel washer are turned into these holes with a wrench.

For combined rivets (which are used to join the coating sheets to each other), the holes are also drilled in the sheets with a diameter of 5 mm, put rivets in the holes, lowering them with the steel rod head down and the aluminum rivet head up. Riveting perform pneumohydraulic gun or special lever tongs. When riveting, the head of the rivet is pressed down and the gripped steel rod is forced upwards. When the rod is drawn, its head crushes the lower cylindrical part of the rivet, thus forming the lower head of the rivet. As soon as the formation of the lower head of the rivet is completed, the metal rod breaks off in a narrowed section and its upper part is pulled out of the rivet.

Steel profiled flooring used in the installation of coatings large blocks, assembled on a conveyor belt. In this case, on the flooring, when assembling into ready-made cards, vapor barrier is applied, a layer of insulation is laid, and a waterproofing carpet is glued.

Very rarely used precast concrete for the device cover. In this case, the slab is laid symmetrically in the direction from the support nodes to the ridge. In the presence of a lantern, the plates are initially mounted on the farm, and then on the lantern from the ridge to the edges.

Что бы оставить комментарий войдите

Комментарии (0)