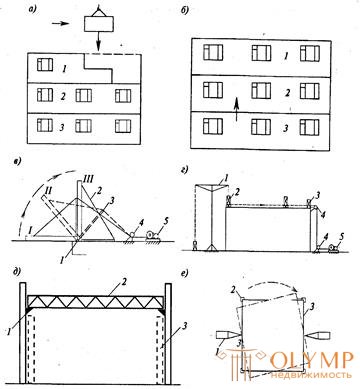

In the construction practice, the following methods of installation of structures were established: building up, growing, turning, sliding and vertical lifting (fig. 16.1).

| Fig. 16.1. The main methods of installation of buildings and structures: a - capacity (1..3 - sequence of installation); b - growth (1 ... 3 –sequence of rise); in - the method of the falling stre-ly; 1 ... 1 II - stages of the structure rotation; 1 - articulation; 2 –stretch; 3 - “falling arrow”; 4 - block; 5 - winch; g - sliding; I - mounting crane; 2 - thrust piece; 3 - the element in the design position; 4 - block of the chain hoist; 5 - winch; e - vertical lift with hydraulic lifts; 1 - hydraulic lift; 2 - raised structure; 3 –Application of supporting structures; e - mon-taj tandem cranes; 1 - mounting crane; 2 - permanent support; 3 - lifting and turning the structure onto the supports |

The method of building is widespread when installing all types of buildings. Installation of elements can be carried out on all three methods of installation - differentiated, complex and mixed. The assembly is mounted on top of the previously installed structures, and it includes slinging, lifting to the design position, mounting the structure on the supports, temporary fixing and alignment of the position, loosening and fixing the structure in the design position. The method consists in successively building up the elements of the building horizontally along the entire length (over the entire floor area), with the continuation of work in the same sequence and on subsequent floors. Separate structures, enlarged linear elements, flat and spatial blocks can be used as mounting elements. The method allows you to organize the construction of the building by any modern methods, with any organization of work, to apply the most diverse complex mechanization of all work, to ensure maximum combination of technological processes in order to reduce the total duration of work.

This method of installation of structures allows wide use of blocks and elements of full factory readiness (sanitary ware cabins, volumetric block rooms), complete-block installation from building structures enlarged into spatial blocks with transferring a part, and sometimes a larger amount of subsequent finishing or general construction and finishing works in factory conditions.

The method of rearing is the sequential construction of buildings, starting with the top floor and ending first. First, on the assembled structures of the underground part of the building, the uppermost structures are assembled and raised, then the elements and structures below are grown to them. The advantage of this method is to perform basic assembly and welding operations at ground level. The method is widely used, in particular in the construction of buildings by means of lifting floors and floors.

In residential and industrial construction, rearing is carried out on guide columns, stiffening cores using jacks and means of tightening structures. When the method of lifting floors initially concreted all floors, including the cover panel. With the help of jacks, the upper covering is raised to a certain height, usually with a finished roof. Further, consistently, in accordance with the established technology, they carry out lifting of one overlap or plate pack to an intermediate height, building up columns, again lifting plates from both intermediate marks and from ground level. When all the floor panels are at their design elevations, they will be equipped with other structural elements, including a hinge of wall panels. The construction of the floors with this method produced from top to bottom.

In the method of lifting floors, initially all floors and the upper floor are raised, which is raised to an intermediate height, prefabricated structures of the upper floor are erected on the upper floor, the whole floor is raised to the level of the floor and connecting

yut with him. Next, on the upper concreted ceiling, the next floor is mounted, raised to the upper one and together they are raised to the design marks. Next, collect the next floor and raise to design marks. All subsequent constructions are assembled and raised to the design position in a similar way.

yut with him. Next, on the upper concreted ceiling, the next floor is mounted, raised to the upper one and together they are raised to the design marks. Next, collect the next floor and raise to design marks. All subsequent constructions are assembled and raised to the design position in a similar way.

The method of rotation is used for structures or structures assembled in a horizontal position, usually at ground level. Lifting structures in the design position is carried out by turning around a fixed hinge with the help of portals, shevrov, masts with tackles, winches, using self-propelled cranes. The task of all these mounting devices and tools is to ensure a smooth rise and turn of the mounted structure from the horizontal to the vertical position. To ensure the stability of the structure when lifting, especially at the final moment of installation in a vertical position, use brake winches and other devices that perceive inertial forces from the movement of the raised system, perceiving lateral wind forces and other loads arising during the ascent.

The way of turning is mounted radio masts up to 120 m high, power transmission towers. Two types of method are most commonly used:

- method of rotation using a self-propelled crane for lifting the top of the structure to an intermediate height with the subsequent lifting of the structure using a winch;

- the method of "falling arrow" - on the structure in the hinge is installed vertically and rigidly fix a high rigid rack, the top of which is connected to the top of the raised structure, thus creating a rigid triangular system. This system is rotated around the support hinge with the help of a winch, the cable from which is fixed at the top of the rack (boom) passes through a stationary block anchored in the ground.

The sliding method is based on the assembly of individual structures into a large spatial block (in the concreting of a large-sized spatial structure) aside from their permanent supports. In the design position, the finished spatial structure is moved along special paths. At the same time, the design either slides (sliding method) or rolls on rollers (rolling method). The method is used in the installation of structures for industrial buildings, during the sliding of structures in the constrained conditions of the site or in case of insufficient lifting capacity of mounting cranes.

The method of vertical lifting is characterized by the fact that the spatial structure is completely mounted on the ground, lifted with the help of lifts (usually hydraulic) slightly above the design mark, supporting structures, most often columns, to which the mounting element is lowered, are brought under it. In some cases, the spatial unit, prepared for installation, is lifted and mounted on supports using two synchronously operating installation cranes.

Methods of installation of elements are an integral part of the project work. Optimization of installation methods is carried out by means of a feasibility study taking into account the determining factors: the design features of the building, the mass of elements, the topography of the site and the required areas, the availability of installation equipment, and standard construction time.

Что бы оставить комментарий войдите

Комментарии (0)