When performing mechanized plastering work, some manual operations are preserved: leveling mortar, plastering slopes and blind spots, small-sized rooms, rubbing husks, grills and chamfers, smoothing ceilings on the ceilings, smoothing out trowels or troweling with ordinary graters, hanging, beacons.

The mechanism for applying the solution is chosen depending on the preparedness of the object, the scope of work and the required solution.

When applying the solution in a mechanized way, there is always a large rebound of the solution, especially from the ceiling. The solution must be collected and reused in the case. Most often it is applied manually on the surface of the walls. To make it easier to collect the solution, the floors are covered with glass or other material. As you work, glassine or sheets move from one room to another. This must be taken into account when recruiting teams and links. If only walls are plastered, then glassine or other sheets are laid only around the perimeter of the premises.

When starting work, all members of the link should know what kind of operations they will perform, how much, etc. At first, the entire team is engaged in preparatory work. As preparation of the work front, the units gradually move to their main work. The organization of work also depends on their composition: whether only walls or walls and ceilings are plastered, are they rubbed with pods or pulled out cornices, or padugs are made by hand.

Consider the possible options for recruiting specialized teams , i.e. teams performing only finishing work and consisting of workers of the same profession.

Organization of work by a brigade of 39 people . The brigade is divided into five units.

The first link consists of 10 people. They are carrying out preparatory work - they caulk window and door frames and the joining of gypsum partition walls to walls and ceilings, as well as install ventilation grids, windowsill boards and carry out other types of training. The second link also consists of 10 people. They plaster slopes, sew seams, rusty between the slabs. The first and second links are mostly manual.

The third link consists of three people servicing the installation, with the help of which they spray and primer.

The fourth link includes eight people. Their responsibilities include leveling the spray and soil solution, applying a hand-applied coating, leveling it, and grouting with a trowel.

The fifth link also consists of eight people. They plaster small, uncomfortable, for mechanized application of the mortar premises (storerooms, sanitary facilities).

Organization of work by a brigade of 28 people . To perform high-quality plaster with the extrusion of the eaves, the team is divided into six units.

The first link consists of four people: two drivers of the 4th category and two workers of the 4th category. The link prepares and transports plaster solutions. One driver works on a mortar mixer, and the second on a mortar pump; he also ensures that the brigade is supplied with a smooth solution. If necessary, one driver can replace the other. Workers bring and sift materials, load them into the bunker and perform other work.

The second link consists of two plasterers of the 5th and 6th grades. They fix vertical and horizontal surfaces, hammer in nails, arrange plaster or mortar marks and fix wooden or metal beacons to them. On the walls, the lighthouses are fixed horizontally, but so that the upper rule can simultaneously serve both to level the solution on it with bead and to draw out the cornices. To do this, the extreme rules on the ceilings and the upper walls are set on the template. This event saves time on hanging the rules for pulling.

The third link consists of four people: one driver of the 5th category, his assistant of the 4th category and two plasterers of the 5th category. The responsibility of the link is the application of spray and soil on the plastered surface, leveling the solution and its collection from the floor.

The work begins with the fact that in the first half of the day they spray the ceilings and walls. Two plasterer level the mortar on the ceilings and walls, if it is applied in places above the level of the lighthouses, and also clear the lighthouses from the mortar, collect the fallen mortar and manually apply it to the well-defined places. In the second half of the day or the next day, which depends on the temperature conditions, the driver with the assistant returns to the room where the spray was sprayed, and a solution of the soil is applied to it. Plasters re-level the applied soil solution, collect the fallen and put it manually on the surface, while cleansing the fry from the solution. These operations are repeated until the solution is applied to the level of the lighthouses. Sometimes in the same room you have to return several times.

The fourth link consists of five people: two plasterers of the 6th category, two plasterers of the 4th category and one working lowest category. The link pulls out the eaves with the usual pattern, cuts the corners with a corner with a manual tweak.

The extrusion is carried out with a lime-gypsum solution, which is applied manually with paddles. Sometimes it is applied with scoops or buckets. A lower-level worker provides plasterers with mortar, gypsum, water, rearranges the tables and arranges the flooring on them. Having finished stretching and dividing the corners, the tables are not removed, since they will be needed by the subsequent links.

The fifth link consists of eight workers: two plasterers of the 6th category, four plasterers of the 4th category and two working lower categories. This link removes the rules from the walls and ceilings, covers the remaining places from them, plastering the slopes and bumps, rubs the husks, ussenka, chamfers, plastering sanitary facilities, corridors, niches and built-in wardrobes. Lower-level workers provide plasterers with a solution, clean and transfer the rules to other rooms, rearrange tables.

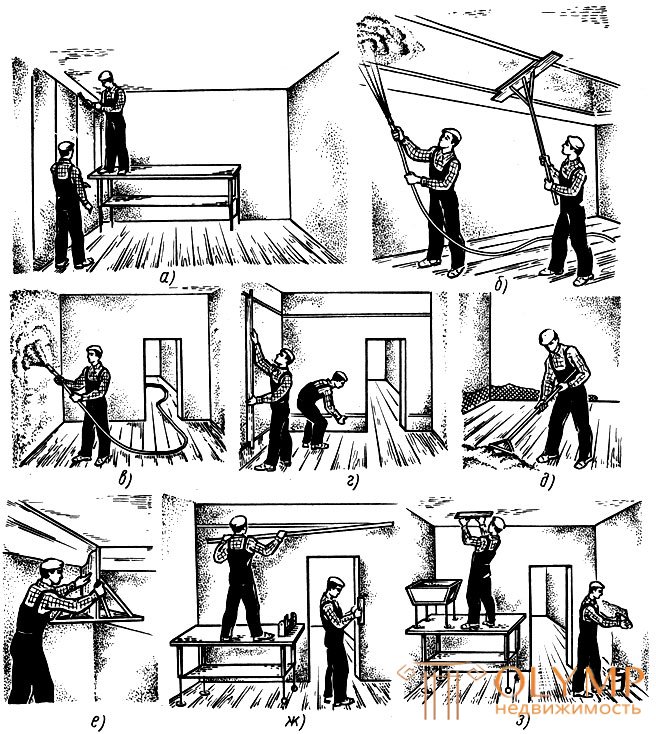

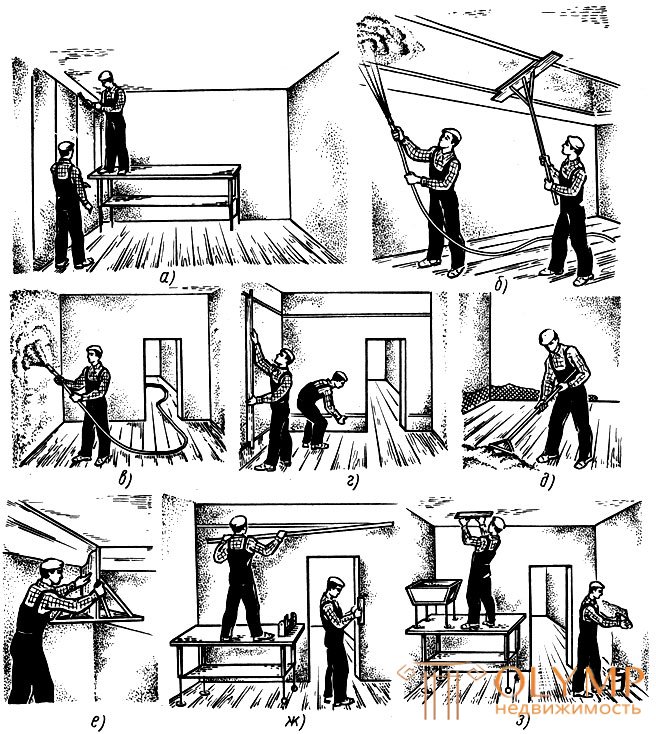

The sixth link consists of five people: three plasterers of the 5th category and two lower-level workers. The link is engaged in the preparation of a solution for a sandless coating and applying it on the walls and ceilings. The applied spread is smoothed and smoothed with trowels. The preparation of the solution with a toe of the necessary materials is performed by the workers of lower discharges. The sequence of work is shown in Fig. 102

Fig. 102. The sequence of works in a mechanized way: a - hanging with the device of beacons, b - applying the solution on the ceilings and leveling it; and cutting corners, OK - removing the rules and finishing the slopes, h - applying a sandless covering and smoothing it down

In addition to specialized brigades, there are complex brigades consisting of workers of various professions who participate in the creation of certain products. An integrated brigade is usually divided into specialized units.

When performing work by integrated teams of end products , the building can be completely building. This form of organization provides the opportunity for the most complete combination of construction processes, the development of related occupations by workers, which ultimately leads to savings in labor and an increase in the quality of work.

Что бы оставить комментарий войдите

Комментарии (0)