The mounting organization accepts the structures arriving at the construction site. Acceptance of prefabricated structures produced by passports for these products, taking into account the permissible deviations in size and picking lists. When accepting delivered products, it is necessary to check:

■ the presence of a stamp of the Quality Control Department of the plant;

■ the presence of axial slips and mark the position of the center of gravity of the structure;

■ the presence of mounting marks for unilaterally reinforced elements;

■ no damage, the correctness of the geometric dimensions, the location and fastening of embedded parts, the presence and passage of channels, holes, etc .;

■ compliance with the front surface of the product requirements of the project;

■ no deformations, holes, cracks, flows;

■ the presence of the necessary grooves, niches, quarters, releases of reinforcement, protective coatings for embedded parts.

If the product has turned out to be of poor quality, it will be rejected, a corresponding claim statement will be drawn up with the participation of representatives of the general contractor, the mounting organization and the manufacturer. The product is repaired, if possible, or sent back to the manufacturer. In exchange for the construction site comes a new, high-quality product.

Storage of prefabricated elements. The labor costs for the storage of structures of the total labor intensity of the installation work for metal structures are 12 ... 25%, for reinforced concrete structures - 13 ... 27%.

Warehouses are placed on a planned site, taking into account the flow of storm and melt water. Warehouses are divided into central at the ways of arrival of goods and on-site.

The size of the stock of prefabricated structures depends on the conditions of delivery and can vary from the full volume of elements to the building almost to zero when the building is installed from vehicles. The usual supply of structures - for 3 ... 7 days of operation of erection cranes. In some extreme cases, the stock of structures is adjusted to 1 month of work.

When storing structures in an on-site warehouse, you must:

■ lay out prefabricated elements and place the piles in the area of the crane, taking into account the sequence of installation;

■ structures with a large mass (or windage) should be located near the installation crane;

■ store prefabricated elements in conditions that exclude their deformation and pollution;

■ on the territory of the warehouse to establish signs of passages and aisles.

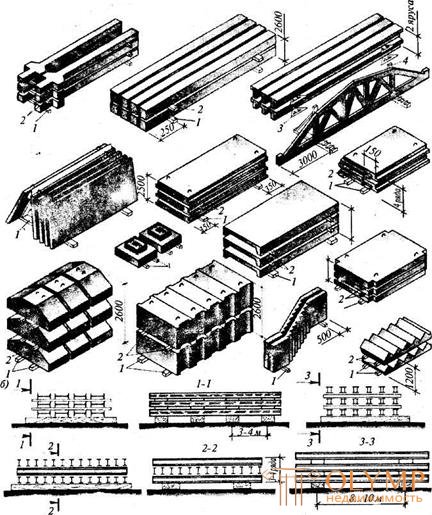

■ All elements are stored on wooden linings of 6x6 and 8x8 cm in size, while alignment of the elements should be ensured, the possibility of the formation of cracks and overvoltages in the concrete structures (Fig. 14.2) is excluded.

|

Fig. 14.2. Storage of reinforced concrete (a) and metal (b) structures: / - linings; 2 - gaskets; 3 - metal supports; 4 - cassette

In stock, heavier structures are closer to the erection crane, and lighter ones are farther away. In order to reduce warehouse space, structures are usually stored in piles. Passages between the piles must be arranged in the longitudinal direction after every two adjacent piles, in the transverse - no less than 25 m. it is necessary to organize so that to have access to any design in order to be able to determine its labeling and preparation for installation.

Slabs, columns, girders, column and spans should be stacked in a horizontal position. The optimal sizes of the stacks: for columns - 4 rows, for bolts and girders - 3 rows, for slabs and floors - up to 10 ... 12 rows, but the maximum height of the stack should not exceed 2.5 m.

Fig. 14.3. Layout of columns in the installation area | In stock, wall panels are installed vertically or obliquely in metal pyramids or cassettes, large-sized partitions are also stored in wooden cassettes, in a position close to vertical. (fig. 14.3), crane girders are parallel to a row of columns at a distance of 40 ... 50 cm from them. The location of prefabricated elements in the warehouse should |

to be such that when they are raised to be installed in the design position, the reach of the boom of the crane does not change, i.e., the boom of the crane does not rise and fall during installation.

Reinforced concrete and metal elements of the frame of one-story industrial buildings are laid at the installation sites: light columns - tops to the foundation, heavy - lower end to the foundation

.

.

Что бы оставить комментарий войдите

Комментарии (0)