Preparation of elements for installation includes: pre-assembly in. flat or spatial blocks, temporary reinforcement of elements to ensure their stability and immutability during lifting, arranging with scaffolding, ladders, fences and other temporary fixtures for safe and convenient operation, securing safety ropes, braces, delays, etc.

Pre-assembly. Pre-assembly is necessary in cases where, due to the overall dimensions or weight of the elements, it is impossible to deliver them to the construction site in a ready, assembled form. From prefabricated reinforced concrete elements (dispatch stamps) delivered, an pre-assembly of farms with a length of 24 m and more, high columns of one-story industrial buildings of a heavy type is manufactured. Sometimes planar blocks are assembled - reinforced concrete columns and girders, creating frame systems, coating trusses delivered in the form of two halves, X panels of walls, drop wells and other structures. In metal structures, assembly at the construction site is carried out for the same structures, as well as coating farms with light and aeration light trusses.

Pre-assembly is carried out mainly in the warehouses of structures or on special sites with the installation of stationary racks. The elements to be enlarged in length, served by crane from the warehouse and placed on the supports of the stand or cassettes in such a way that their longitudinal axes coincide. Then make the fitting of the ends or releases of the reinforcement to achieve alignment of the elements or individual rods. After installing additional clamps and welding rods, assemble the formwork and concreting the joints. The class of concrete, which concretes the joint, and its strength after hardening is established by the project. Usually, the class of concrete is taken the same as that of the elements being joined, or one class higher.

In recent years, the integration of structures into assembly and assembly-technological blocks has been widely used. Such consolidation significantly reduces construction time, as it is conducted in parallel and even ahead of the construction of the building. Pre-assembly with significant amounts of work on enlarging structures produced at assembly sites equipped with stands or conductors, allowing to fix the structure and carry out their alignment and straightening during assembly; sometimes equip conveyor lines. Prefabricated sites are located in the area of installation cranes or near the objects to be mounted, or near warehouses, and conveyor lines - near objects.

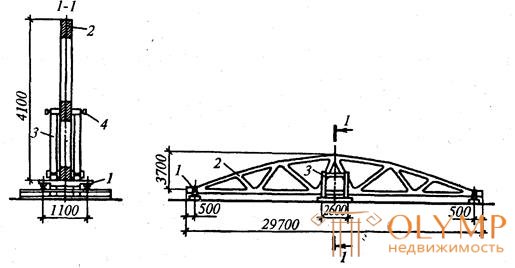

Integration into blocks is most common when installing coatings of one-story buildings on metal trusses and beams. Blocks the size of a building cell are enlarged from the trusses in pairs with their connections, runs, and often also stamped metal flooring or ready-made shields made of lightweight materials are laid on the ground. Often such a spatial unit includes: two subrafter trusses, three truss and lantern trusses, trunks for lanterns and lanterns, steel profiled flooring on top, as an element of the coating.

Reinforced concrete trusses and columns are enlarged in the warehouses of building structures and from there are supplied to the assembly in enlarged form. If it is difficult or even impossible to transport such an assembled element, the enlargement of the structure is carried out at the installation site, i.e., in the area of operation of the assembly crane. However, the work on consolidation of structures in the area of mounting cranes in most cases is unproductive. Therefore, if transportation conditions allow, it must be carried out at special sites of the pre-assembly equipped with lifting equipment and assembly-welding devices. In order to reduce transportation costs, these sites should be located as close as possible to the objects to be mounted.

For maintenance of assembly sites, it is more rational to use a gantry crane, which makes storage much easier, because structures can be distributed evenly over the entire area, regardless of their weight. The use of gantry cranes for the mechanization of pre-assembly operations reduces the cost of these works, reduces the need for railway and crawler cranes with a large carrying capacity, the cost of operation of which is 1.5 ... 2 times higher.

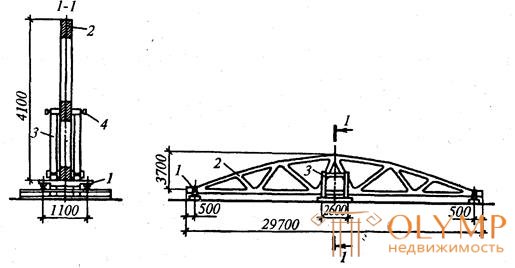

Reinforced concrete trusses are enlarged in a vertical position in special racks of cassette type. The cassettes are installed under two nodes of each semi-farm (Fig. 14.4). Under the supporting nodes make them deaf, without devices for adjustment, and in the span - with adjusting devices. The position of the junction of the assembled elements is adjusted with the help of mechanical or hydraulic jacks. The consolidation of reinforced concrete columns is carried out in a horizontal position, and the alignment of the abutting elements is provided by special conductors.

For pre-assembly of metal structures arrange stationary racks on special sites near the objects under construction. Metal trusses and crane girders, due to their large transverse flexibility, are enlarged mainly in a horizontal position.

Game: Perform tasks and rest cool.11 people play!

Play game

Fig.14.4. Rack for the consolidation of reinforced concrete trusses:

1 single cassettes; 2 semi-farms; 3-pair cassettes; 4 horizontal screws

sometimes enlarged farms with a length of 24 m and more, including with lanterns. Stacked horizontally parts of the enlarged elements are combined on the rack with assembly holes and fixed with bolts or plugs. In the absence of assembly holes, the correct alignment of the abutting elements is checked with the help of clamps attached to the girder rails. The design of the rack allows you to first weld the upper and lower belts from the top, then to avoid ceiling welding, the enlarged element is turned over to another plane and the joints are welded on the other side.

Game: Perform tasks and rest cool.11 people play!

Play gameThe number of stops of the conveyor varies from 4 to 16, for convenience, the finishing posts are equipped with heat sinks, which makes it possible to carry out the processes regardless of weather conditions.

Temporary strengthening of structures. Temporary amplification is carried out for the perception of installation effort. Structural reinforcement is used when the design design scheme and the forces arising during the lifting of an element do not coincide, which may lead to a loss of stability and durability of the structure or its individual parts and assemblies during lifting. The need for such reinforcement to a greater extent relates to metal trusses, whose belts, with a large non-disseminated length, may turn out to be insufficiently stable and rigid when lifting.

In the process of installation, many structures are in conditions that differ from the conditions of their work during operation, although the loads acting on them are usually less operational, but they are almost always applied in places that do not correspond to the design scheme. In order to avoid deformations, structural elements and blocks of structures that do not have sufficient rigidity in the process of transportation and lifting increase, increasing their rigidity, and, if necessary, strength. Need

Fig. 14.5. Reinforcement belts metal I-beam farm before lifting: 1 - strengthening the walls of the farm; 2-farm; 3 - shelf reinforcement | Gains are checked by calculation. In projects of works, there should be specific recommendations for reinforcement of structures for the period of transportation, lifting or addition of necessary strength to the structure. The most frequently strengthened columns are large heights, the lower parts of two-legged columns, steel and wooden trusses, arches and frames of large spans, elements of prefabricated reinforced concrete shells, reinforced concrete arches, steel cylindrical shells, elements of sheet structures. Strengthening high columns that do not have sufficient bending resistance from their mass is produced by tensioning a pair of cables attached to steel temporary stops. Tension creates a bending moment, the opposite of the moment arising from the mass of the column. Metal trusses are usually raised by the nodes of the upper belt. In the process of lifting for knots in the middle part of the truss, in the lower belt of the truss, compression forces arise, while lifting at the knots at the ends of the truss, off-design stresses appear in the upper belt; All this can lead to a loss of stability element. If the truss was not designed for installation efforts, then for |

Game: Perform tasks and rest cool.11 people play!

Play gameOften it is necessary to strengthen and two-branch metal columns, the rise of which is carried out by turning with hinged fastening of one of the branches. In this case, in order to prevent bending deformations, individual lattice braces are reinforced.

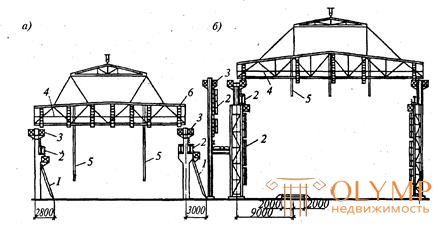

Arrangement and preparation of structures for installation. Arrangement of structures to be assembled implies their equipping with hinged scaffolds, attached and hinged ladders, hinged cradles (Fig. 14.6). This arrangement is arranged in order to ensure safe working conditions for installers at height. Inventory mounted scaffolding, platforms and ladders are fixed to the mounted elements at their installation sites.

Fig. 14 6. Arrangement of frame structures during installation:

a - reinforced concrete; b - steel; 1 - ladder; 2 - mounted ladder; 3 - mounted scaffolding; 4 - safety rope; 5 - inventory struts; 6 - hinged cradles

Game: Perform tasks and rest cool.11 people play!

Play gameScaffolds used for installation of structures are divided into assembly and installation. Assembly scaffolds serve as temporary supporting supports for structures during installation, and the mounting scaffolds are working. They carry out various operations: aiming joints, welding of assembly joints, monolithing, etc. For work at highly located assemblies in the surfaces of large-span buildings, towers are used - retractable or of constant height, moved along rail tracks. On the towers arrange assembly sites for the assembly of structures. Such towers can carry the functions of assembly and installation.

Installation platforms are of two types: ground, installed directly on the ground or other support, used when performing installation work at a relatively small height; suspended and mounted, which are attached to the structure to be mounted before it is lifted and lifted together with it, or hung on the structure after its installation. Usually such scaffolding is used for installation at a considerable height. As a ground scaffold, use the scaffolding and ladders (Fig. 14.7) for work at a height of up to 3.2 m and side ladders with platforms for work at a height of up to 14 m.

Scaffolds used for installation of structures are divided into assembly and installation. Assembly scaffolds serve as temporary supporting supports for structures during installation, and the mounting scaffolds are working. They carry out various operations: aiming joints, welding of assembly joints, monolithing, etc. For work at highly located assemblies in the surfaces of large-span buildings, towers are used - retractable or of constant height, moved along rail tracks. On the towers arrange assembly sites for the assembly of structures. Such towers can carry the functions of assembly and installation.

Installation platforms are of two types: ground, installed directly on the ground or other support, used when performing installation work at a relatively small height; suspended and mounted, which are attached to the structure to be mounted before it is lifted and lifted together with it, or hung on the structure after its installation. Usually such scaffolding is used for installation at a considerable height. As a ground scaffold, use the scaffolding and ladders (Fig. 14.7) for work at a height of up to 3.2 m and side ladders with platforms for work at a height of up to 14 m.

Fig. 14.7. Means of scaffolding:

a- mobile scaffolding; b - step-pad; in - a ladder with a platform; Mr. hanging cradle with a ladder; / - ladder sections; 2 - fencing; 3 - mounted platform; 4-screw clamp; 5 - column; b - cradle; 7 - stairs; 8 - holes for mounting the cradle; 9 –girl

Suspended ladders and scaffolding, mounted on the columns with clamps and embedded parts, are located at the junction of crane girders, trusses and trusses, girders, etc. Hanging cradles with ladders are hung on beams and trusses.

Assembly platforms, ladders and other devices for safe work at height are made of steel and aluminum alloys. They should be light, reliable, convenient for installation and removal after completion of work.

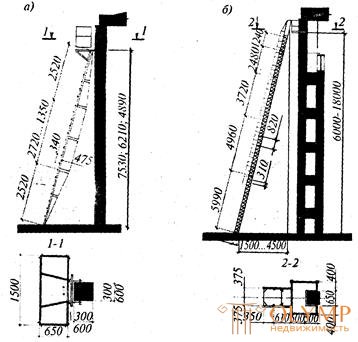

Ladders with platforms are the main element of arrangement of columns for fastening trusses and crane girders to columns with a small height of the building (Fig. 14.8). There are two main types of installation ladders with platforms: with a bearing structure in the form of truss or lattice truss. The first type is designed to perform work at heights up to 7.4 m, the second - up to 14 m. The upper part of the ladder is fixed to the column with clamping bolts, the lower one is supported with sharp stops against the ground or fixed with rods to the column.

Suspended ladders are designed with a height of 3.7 and 2.8 m with and without a safety basket; they are hung on collars specially fixed on columns on the ground, or embedded parts of columns. Clamps are of two types - normal for attachment to columns at the crane console and lightweight for mounting on the columns at the places of fastening of trusses or covering beams. The main way of mounting is for the upper hooks of the stairs. Clamps can be hung on columns of different widths; the lack of construction clamps - in the complexity of their removal after installation.

Fig. 14.8. Ladders freestanding:

Game: Perform tasks and rest cool.11 people play!

Play gameIn reinforced concrete columns it is much more convenient to carry out a hinge plate of scaffolding and stairs for embedded parts. For steel columns, the same hinge elements are used as for reinforced concrete, but these elements are welded not directly to the embedded parts, but directly to the column.

The mounting cradles, mounted on the beams, are intended for the design fastening of the beams after the preliminary installation on the mounting bolts. Ladders with cradles, hung on the upper belt of a rafter or subrafter truss (steel or reinforced concrete), are used to fasten ties, runs, struts and monorails. Ladders are attached to trusses for horizontal or inclined belts, and the cradles are hung on them with hooks behind the steps at any place in height. The cradle can be hung independently on the farm.

When installing medium and heavy columns on them before lifting hang mounting stairs and platforms-scaffolding. Ladders are made by separate links up to 4 m long.

Что бы оставить комментарий войдите

Комментарии (0)