For many years, galvanized steel pipes were the main material for the creation of water supply systems. But, over time, their popularity has decreased in view of the emergence of a new material such as polymers, of which now make plastic pipes for water supply. They made the same revolution in the market as cast iron at the end of the 14th century.

Contents

Today, polymer products have several varieties, characterized by different properties, advantages and disadvantages. Common advantages of using plastic pipes for water supply include:

The disadvantages of plastic pipes for plumbing are very peculiar and are not obvious drawbacks. Among them, it is possible to single out only the fact that they cannot be used among fire-fighting water supply systems, have limitations on the temperature of the water being conducted and differ in their own installation technology for each type of pipe and polymer.

PVC plastic pipes for water supply are pioneers in the use for the manufacture of water supply systems. It implies the arrangement of hot and cold water supply systems. They are successfully used for technical and food water. The following features distinguish them from other types:

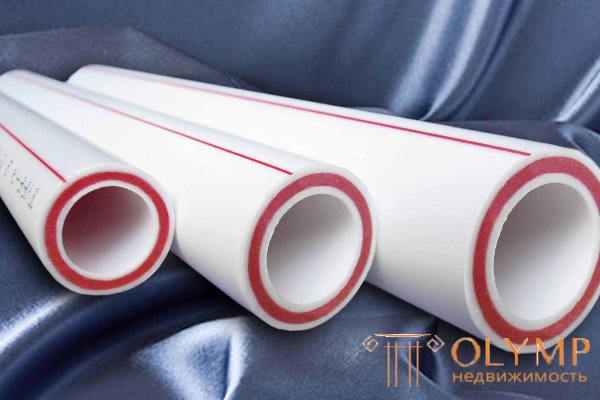

They may be multi-layered or single-layered. The standard pipe length is four meters, and the outer diameter varies from 16 to 125 millimeters. The joints of pipe fittings are arranged by means of special mounting equipment using the method of thermoplastic welding. Special fittings with existing threads allow you to connect polypropylene pipes with metal risers. Most often used in the arrangement of cold water systems, less often - hot or heating.

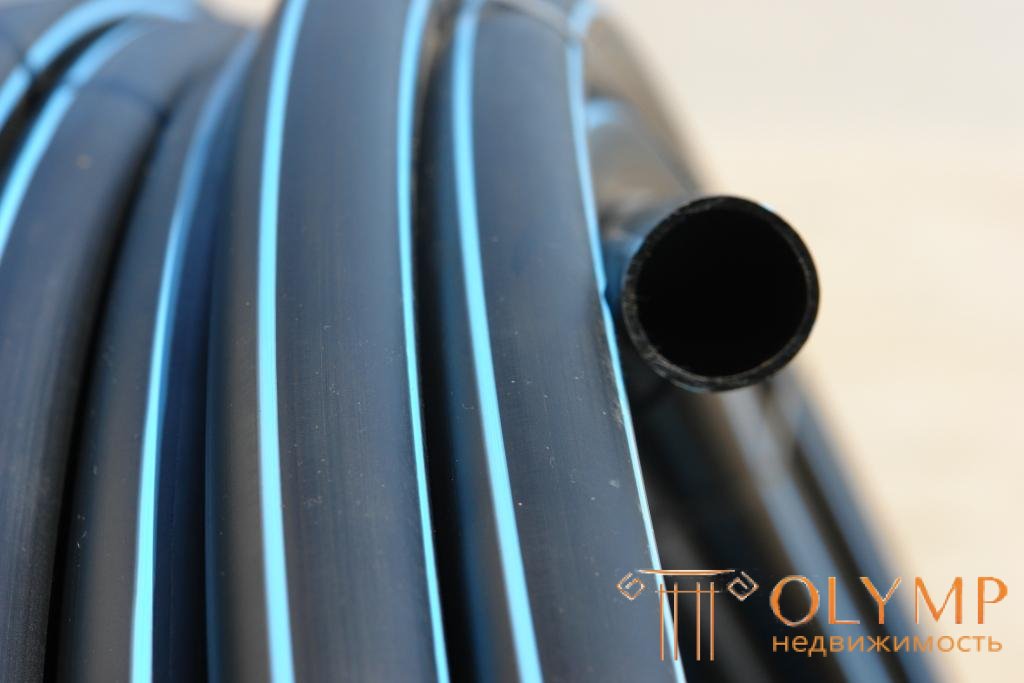

These plastic pipes for water supply differ from other types by the lowest limiting temperature at which they can work. It is equal to -20 degrees Celsius. They are divided into two types: "C" - medium and "T" - heavy. In the first case, the working pressure is about six atmospheres, and in the second up to 10 atmospheres. Widespread pipes of this type received in the arrangement of sewage and drainage systems. The diameter varies from 20 to 160 millimeters. The connection is made by brass or polypropylene fittings, as well as electrofusion couplings or butt welding. Polyethylene pipes are produced only at 15 plants of the Russian Federation and neighboring countries.

They are created by processing the material under high pressure, as a result of which they become more durable and resistant to various temperature influences. The process is called "stitching." There are several ways to crosslink polyethylene:

Such pipes are reliably protected from the penetration of oxygen inside, are used to create a system of snow melting, installation of water floors and water mains.

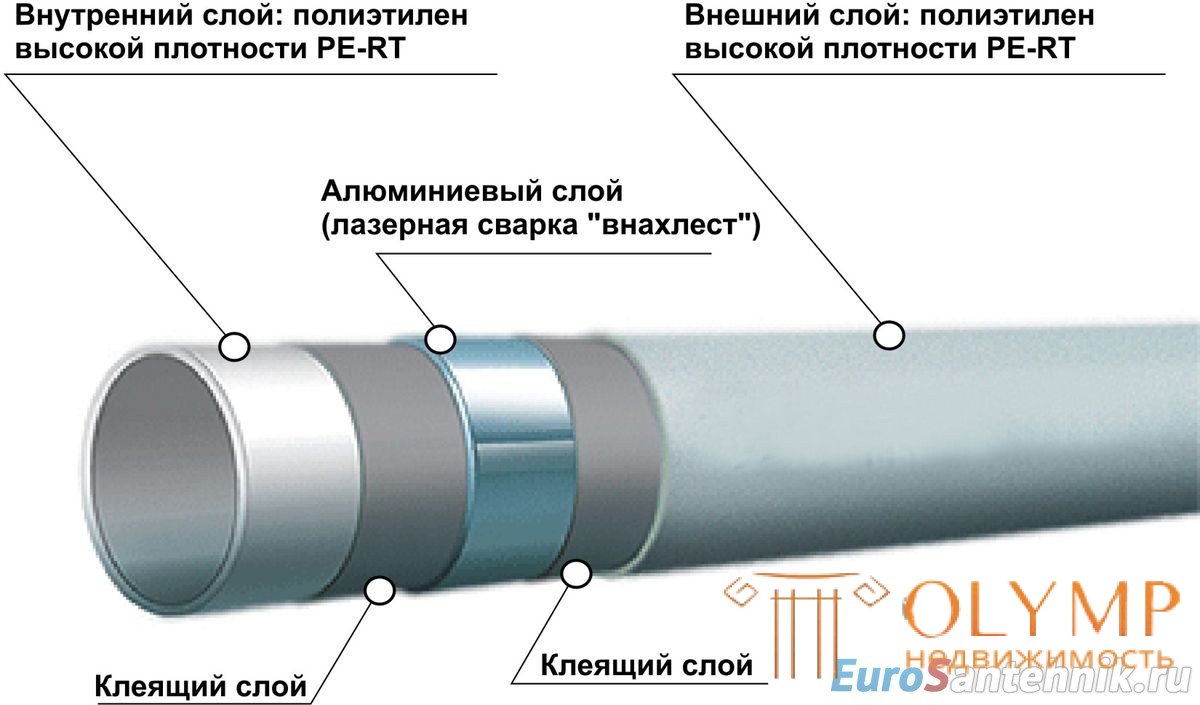

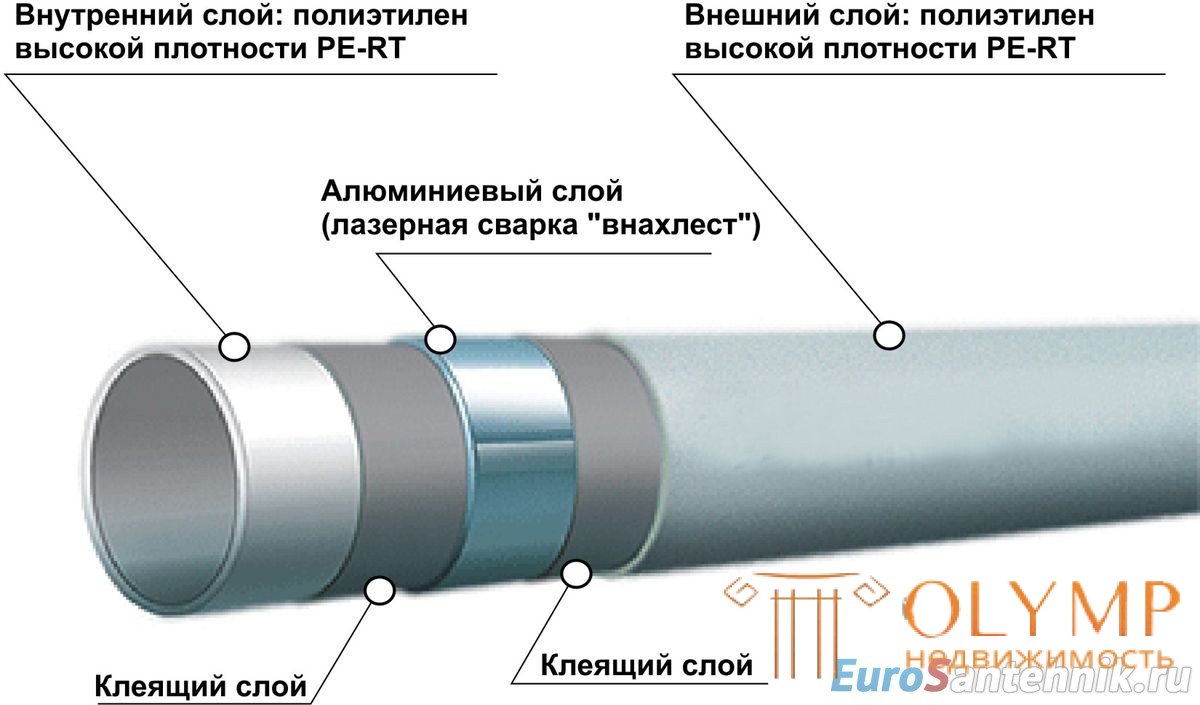

The youngest subspecies of plastic pipes for plumbing. For the first time appeared about one decade ago in the territory of England. They are a type of metal-plastic pipes, but they are equipped with a special layer of aluminum foil. Thus, the creators have achieved a reduction in the coefficient of linear expansion of the pipe. Have a complex composition of five layers.

Main advantages:

1. Welding or so-called soldering pipes. Today it is actively used in PPR plastic pipes for water supply. The process is based on melting the ends of the pipe and fitting in a special welding machine and then fastening them together. This is how a solid connection is achieved.

Pipe welding example:

2. Using crimp fittings with a special press machine. This method is applicable to metal and plastic pipes. Pipe joints are interconnected by special fittings and then pressed by a special press machine.

3. Flange method. With this method, the pipes can later be corroded among themselves. The connection takes place with a special flange. Special rubber gaskets are responsible for tightness.

Among all classes of pipes made of polymers it is difficult to choose one, it all depends on the requirements for the water supply system. We try to work with metal-plastic pipes and pipes made of cross-linked polyethylene. There are several reasons for this.

The first and most important - these pipes are more environmentally friendly than the same CPD pipes. Second, these pipes have a solid structure and their joints are all on the surface. And the third reason - pipes are relatively affordable.

Что бы оставить комментарий войдите

Комментарии (0)