Calculation and design of panels.

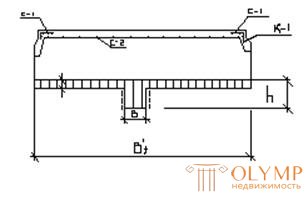

The shape of the cross-section distinguishes ribbed hollow core and solid panels. Ribbed panels are used mainly in industrial buildings. The width of the panels is 1.0 ... 1.8m through 0.1m; section height of the panels is 25 ... 35 cm. Hollow-core panels with smooth ceiling surfaces are mainly used in civil engineering. The most common panels with round voids are 1.4 ... 2.4m wide through 0.1m, with a section height of 20 ... 24 cm. Panels with oval cavities are less adaptable to manufacture and are rarely used recently.

Solid panels can be single-layer and double-layer with a top layer of lightweight concrete; the latter have high thermal insulation properties, low sound conductivity and are used in the attic floor

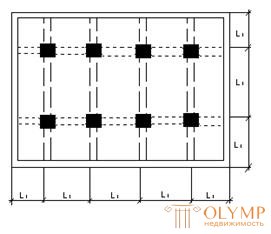

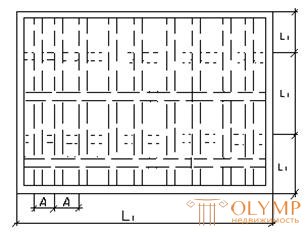

Monolithic ribbed floors with beam plates.

Monolithic ribbed floors consist of slabs, secondary beams and main beams, which are concreted together and constitute a single

construction The slab rests on the secondary beams, and the secondary - on the main beams, the supports of which are supports and walls. Design of monolithic overlap includes the layout of structural schemes, calculation of plates, secondary and main beams and their design. The main beams are located parallel to the longitudinal walls, or perpendicular to them and has a span  1 = 6 ... 8m.

1 = 6 ... 8m.

Span of secondary beams  2 = 5 ... 7m, plates

2 = 5 ... 7m, plates  = 1.5 ... 3m. The overlaps are made of concrete of class B15 and reinforced with reinforcement of class Bp-1, B-1 and rod reinforcement of class AI, AII, AIII.

= 1.5 ... 3m. The overlaps are made of concrete of class B15 and reinforced with reinforcement of class Bp-1, B-1 and rod reinforcement of class AI, AII, AIII.

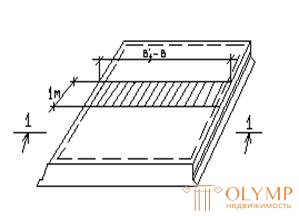

Calculation and design of the beam plate.

Distinguish slabs of monolithic ceiling beams and supported on the contour . Girders have an aspect ratio of L1 / L2> 2; supported along the contour of L1 / L2 £ 2. Beam slabs work in one shorter direction. In the other (long) direction, the bending moments are so small that they can be neglected. In slabs supported along the contour, bending in both directions must be taken into account. In the ribbed directions more often beamed slabs. For the calculation of such slabs, a strip 1 m wide is distinguished and is considered as a continuous beam supported on secondary beams and external walls. The calculation of the plate is made taking into account the redistribution of forces, and in order to simplify the design, it is assumed: in the first span and on the first intermediate support  In medium spans and medium supports

In medium spans and medium supports  The estimated value of the average spans is equal to the distance between the edges of the secondary beams

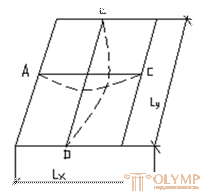

The estimated value of the average spans is equal to the distance between the edges of the secondary beams  , extreme spans (with the free unlocking of one end of the slab on the wall) - the distance and edge of the beam edge and the axis of the support on the wall

, extreme spans (with the free unlocking of one end of the slab on the wall) - the distance and edge of the beam edge and the axis of the support on the wall  . The area of the reinforcement in the calculated sections is defined as for a rectangular section of width = 100cm and height

. The area of the reinforcement in the calculated sections is defined as for a rectangular section of width = 100cm and height

The reinforcement of multi-span beam plates is carried out, as a rule, with rolled nets. In this case, continuous reinforcement with rolled nets with longitudinal working reinforcement (¯ £ 5mm) and separate reinforcement with flat or rolled nets with transverse working reinforcement are adopted. With continuous reinforcement, the main reinforcement with area As is selected according to the moment  , and in the first span and above the first support, additional reinforcement As is installed, selecting at the moment

, and in the first span and above the first support, additional reinforcement As is installed, selecting at the moment

. M =

. M =  .

.

Calculation and design of the secondary beam.

The secondary beam is calculated as a non-split structure based on the main beams and external walls, on a uniformly distributed load (  ) transferred by the slab from the band vf, and the load from the fold. Mass g2 beams =

) transferred by the slab from the band vf, and the load from the fold. Mass g2 beams =  ;

;

Bending momentary and transverse forces at equal spans ahead of the formula: in the first span of M1 =  ; on the first support from the edge, MV =

; on the first support from the edge, MV =  ; in other supports and over the spans M =

; in other supports and over the spans M =  ; Qa = 0.4

; Qa = 0.4  ; Q = 0.6; on the first industrial support on the right and on all other supports: QHF =

; Q = 0.6; on the first industrial support on the right and on all other supports: QHF =  : where ... is the calculated span of the secondary beam, assumed to be equal to the clear distance of m. main beams, unlocking to external walls; distance from the axis of the support on the wall to the edge of the main beam.

: where ... is the calculated span of the secondary beam, assumed to be equal to the clear distance of m. main beams, unlocking to external walls; distance from the axis of the support on the wall to the edge of the main beam.

1. Cooker

2. Secondary beam

3. Main beam

4. Column

The dimensions of the cross-section are specified by the moment on the first intermediate support, taking  then

then  . Then they unify the sizes and select the working reinforcement in the calculated norm of the section: in the first and middle spans — as for such a section, on the first intermediate and middle supports — as for the rectangular width c. The effect of negative mom-ba in medium spans is calculated as for a rectangular section. The calculation of the cross section is performed as for a rectangular section. Calculation of the cross-section is performed for 3 inclined sections: for the extreme free support (for QA) and for the first intermediate support for the left and right (for Qb.l and QB.h). The secondary beams are reinforced in a span by flat welded frames, and on intermediate spans by two identical roll nets with transverse working reinforcement that are rolled over the main beams. In order to save reinforcement, the overhead meshes are displaced one relative to another.

. Then they unify the sizes and select the working reinforcement in the calculated norm of the section: in the first and middle spans — as for such a section, on the first intermediate and middle supports — as for the rectangular width c. The effect of negative mom-ba in medium spans is calculated as for a rectangular section. The calculation of the cross section is performed as for a rectangular section. Calculation of the cross-section is performed for 3 inclined sections: for the extreme free support (for QA) and for the first intermediate support for the left and right (for Qb.l and QB.h). The secondary beams are reinforced in a span by flat welded frames, and on intermediate spans by two identical roll nets with transverse working reinforcement that are rolled over the main beams. In order to save reinforcement, the overhead meshes are displaced one relative to another.

Calculation and design of the main beams

Permanent and temporary concentrated loads from secondary beams, equal to their support reactions, are transmitted to the main beam. In addition, the own weight of the main beam is taken into account.

In terms of design, the main beam of a monolithic ribbed floor is considered as a rifled load loaded with concentrated weights.

The dimensions of the cross section of the main beam specify by the moment at the verge of the column, then

6 ……… 8)

6 ……… 8)

as above the main beams there is a reinforcement of the slab and grids of the secondary beams.

The calculated cross section of the main beams is taken in flight on a rectangular support (since a flexural moment occurs at the top, therefore this zone is stretched, and the concrete does not work on the bracings and the section of the tavern section is not taken into account).

In the span, the main beam is reinforced with 2 ... 3 flat frames, connected before installation in spatial frames with the 3rd frame, it is usually not brought to the verge of support, breaking off in accordance with the moment support. On the support, the main beam is reinforced with two independent frames and working reinforcement at the top. To the main beam, the load from the secondary beam is transmitted through the compressed zone of the latter. This load is perceived by the transverse reinforcement of the main beam, and if necessary, additional grids will be made.

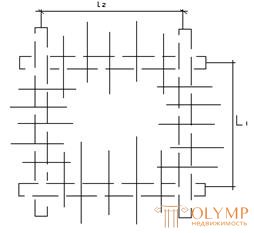

Monolithic ribbed floors with slabs supported along the contour.

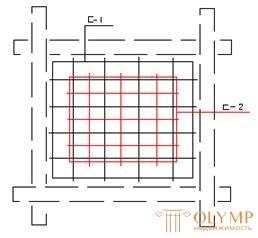

There are two types of such overlaps. In the ceilings of the first type, the beams are located along the axes of the columns, the pitch of which is 4 ... 6 m. beams have the same height of cross sections. Aspect ratio 1 ... 1.5. Type 2 ceilings, called cleon, are distinguished by a more frequent arrangement of beams, the absence of intermediate columns and small dimensions of plates not exceeding 2 m. The ceilings with slabs supported along the contour are less economical than those with beamed slabs with the same grid of columns, but aesthetically they iron better and are used to overlap public buildings: halls ... The slab supported along the contour works in 2 directions and is reinforced connected by grids, laid in the span along the bottom, and at the supports (above the beams) - on top, with the spans of the slab more than 2.5 m, separate reinforcement is used.

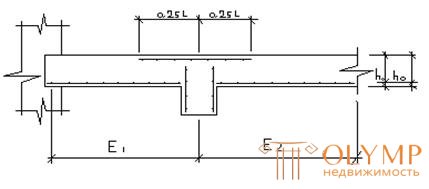

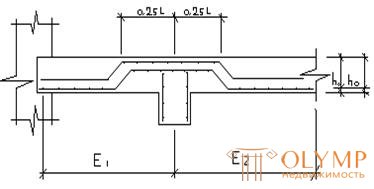

The lower reinforcement is made of two grids with the same area of the working reinforcement section in each direction. In order to save, each grid is brought to the supports, and the other is placed in the middle part and is not brought to the supports at a distance of 1 / 4L1 if the plate is adjacent to the beam, or to 1/8 L1, with free unlocking of the plate.

The upper reinforcement of the slab (above the beams) is made in the form of grids, in which the working rods are arranged in the direction perpendicular to the beam, and enter the spans through one at a distance of 1 / 4L1 and 1 / 6L1.

Questions for self-test.

1) What design is called a beam?

2) What design is called a slab?

3) What slabs are called beams? What slabs are called supported on a contour?

4) Draw a beam cage diagram.

5) What is the span of the main beams?

6) What is the span of the secondary beams?

7) What is the span of the slab?

8) What is the overlap thickness?

9) What are the components of the load on the plate?

10) What is constant load? How to get a load of 1m2 slab and floor?

11) What is the cargo area when calculating the plate?

12) In which direction does the bending moment occur when calculating the slab?

13) The design scheme of the beam plate?

14) Draw a plot of bending moments in the presence of a beam plate?

15) Do the calculation of the strength of the inclined section for the plates? Why?

16) How to determine the area of longitudinal reinforcement for the plate? (at the bending moment as for a rectangular section with a width of 100 cm and height h? in two moments of the average and first span).

17) Show reinforcement slabs. What is the% reinforcement plates?

18) How to determine the bending moments of secondary beams with equal spans?

19) How to determine the transverse forces on the slabs of secondary beams?

20) In which sections are selected the working reinforcement of the secondary beams?

21) How is the load on the main beam?

22) In which direction are the plates supported along the contour?

23) What is the general principle of panel design?

24) What is the load on 1 m2 of panel?

25) How to determine the load area of the load per unit length of the panel?

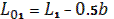

26) How to determine the estimated span panel?

How to calculate the strength

Что бы оставить комментарий войдите

Комментарии (0)